Multi-loop control device in vehicle braking system

A technology of vehicle braking and control device, applied in the direction of brake transmission, hydraulic brake transmission, brake, etc., can solve the problems of the brake wheel cylinder not working, the loss of brake fluid, the failure of the brake system, etc. Improved shutdown effect, guaranteed braking performance, improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

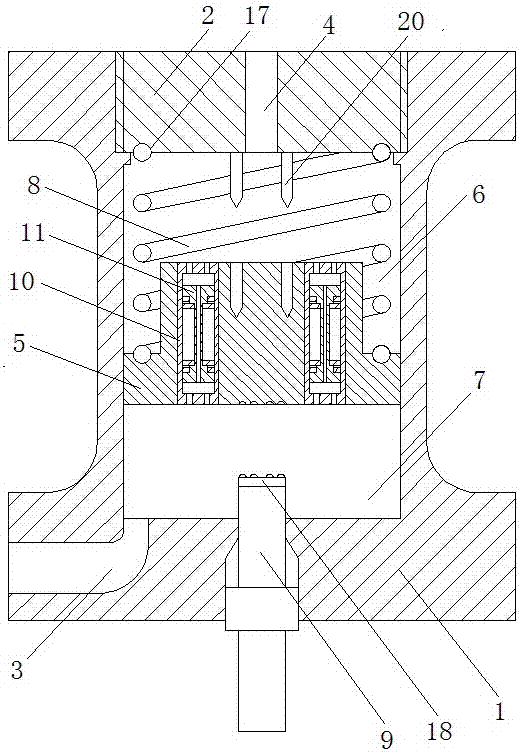

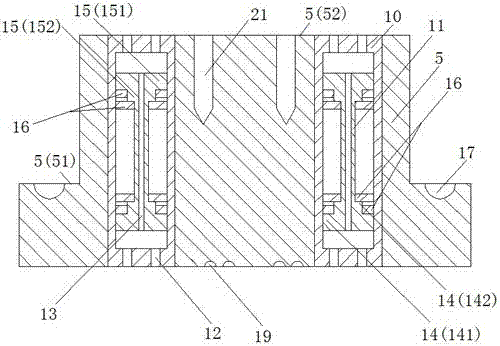

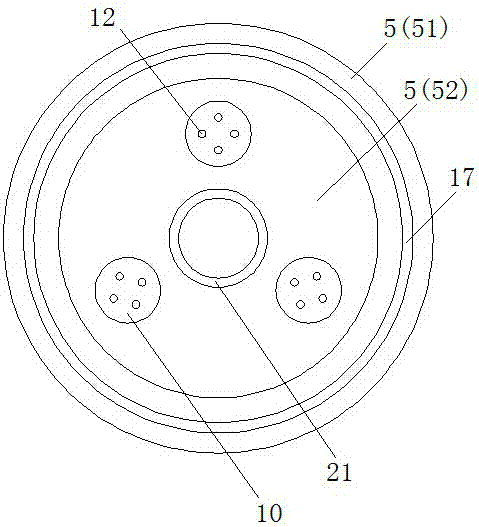

[0029] Such as figure 1 A multi-circuit control device in a vehicle braking system is shown, which includes a control cylinder 1, the upper end of the control cylinder 1 is provided with an end cover 2, and the inside of the control cylinder 1 is provided with a cavity. 1 is provided with an oil inlet 3 and an oil outlet 4 extending to the inside of the cavity, and the end cover 2 and the control cylinder 1 are connected by threads. A piston 5 is arranged in the cavity, and its side end surface is attached to the inner wall of the cavity. In the cavity, the cavity area between the piston 5 and the upper end surface of the cavity is the upper cavity 6, and the piston 5 and the cavity The cavity area between the lower end surfaces is the lower cavity 7, the oil inlet 3 is connected to the lower cavity 7, the oil outlet 4 is arranged in the end cover 2, and it is connected to the inside of the upper cavity 6; The end of the oil outlet 4 in the upper cavity 6 is located at the ax...

Embodiment 2

[0039] As an improvement of the present invention, in each diversion valve, the diameter of the first diversion hole is 3 millimeters, and the diameter of the second diversion hole is 0.8 millimeters, which can pass through the first diversion hole and the second diversion hole. The micro-diameter of the hole is set to form a good throttling effect on the brake fluid.

[0040] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0042] As an improvement of the present invention, such as Figure 4 As shown, in each diversion valve, the axis of the second diversion hole 13 inside the diversion valve core 11 extends in a corrugated shape in the vertical direction. With the above design, when the brake fluid flows inside, the corrugated structure of the second diversion hole can extend the flow path of the brake fluid, so that the second diversion hole can save the brake fluid. The flow effect is more significant, so that the hydraulic pressure of the brake fluid in the lower cavity can be guaranteed relative to the upper cavity, so as to improve the working performance of the control device in this application.

[0043] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com