Winding device of tubular medical instrument

A medical device, tubular technology, applied in the field of coiling devices for tubular medical devices, can solve the problems of slow manual packaging, poor product quality, low work efficiency, etc., to avoid excessive local coiling, good product quality, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

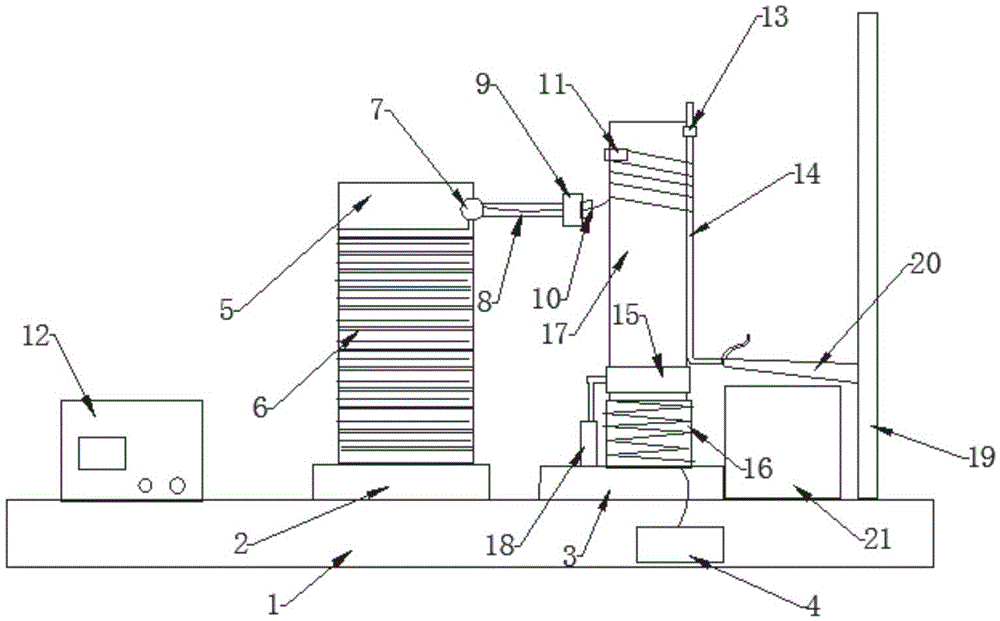

[0020] like figure 1 As shown, a coiling device for a tubular medical device of the present invention includes an operating platform 1, a first fixed base 2, a second fixed base 3, a motor 4, a raw material box 5, a tubular medical device 6, a swivel joint 7, a guide Tube 8, length meter 9, anti-off clip 10, winding clip 11, numerical control instrument 12, easy-to-pull clip 13, finishing winding belt 14, unloading ring 15, elastic rod 16, rotating shaft 17, lifter 18, support rod 19, finisher 20, wrapper 21;

[0021] Numerical control instrument 12, first fixed base 2, second fixed base 3, wrapper 21 and strut 19 are arranged in sequence from left to right on the operating platform 1;

[0022] The first fixed base 2 is provided with a raw material box 5, and a tubular medical device 6 is housed in the raw material box 5. The upper end of the raw material box 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com