Drinking water packaging container

A packaging container and drinking water technology, applied in the direction of containers, transportation and packaging, and anti-rot containers, etc., can solve the problems of heavy weight, high cost, drinking water pollution, etc., achieve small size and/or weight, and reduce economic burden , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

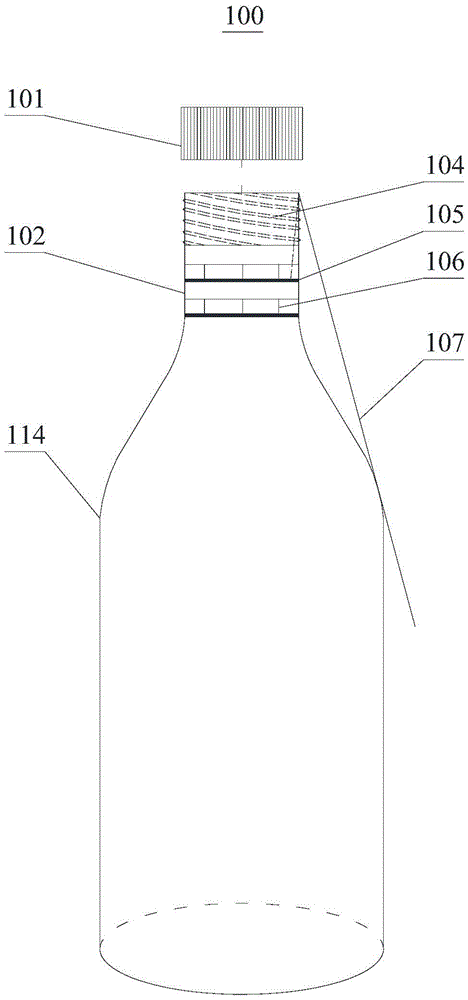

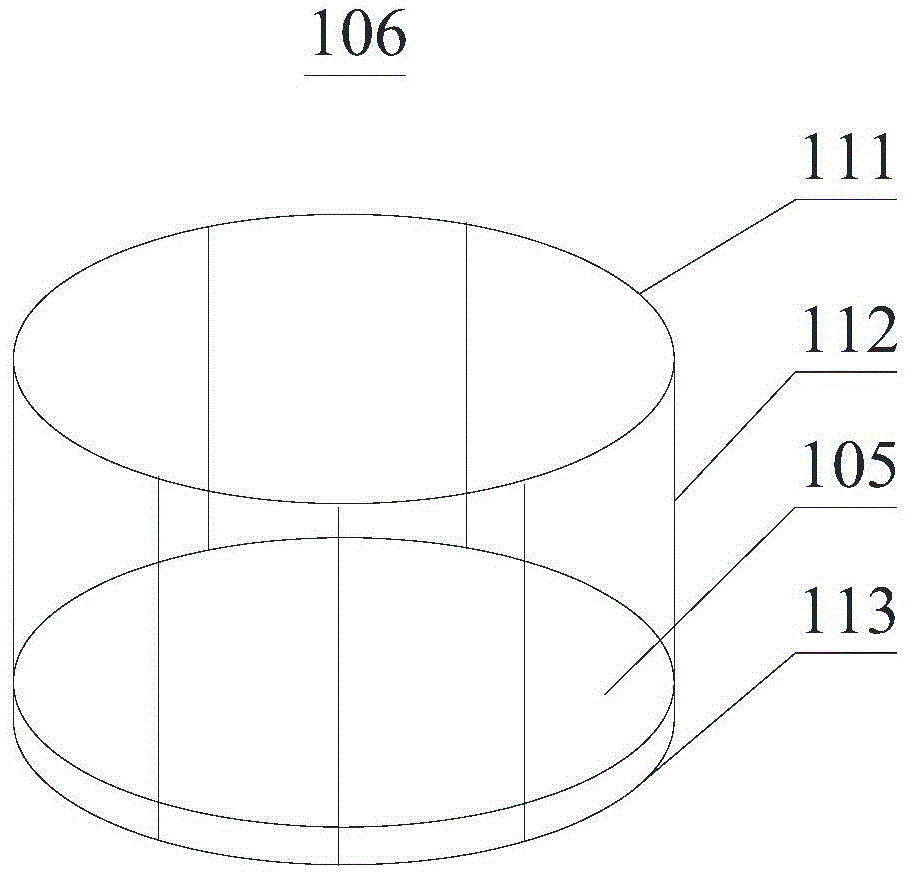

[0028] see figure 1 As shown, embodiment 1 provides a kind of drinking water packaging container 100, has the container body 114 of bottle mouth and the container cover 101 that is used to seal container body 114, is provided with non-slip texture on the container cover 101, and container cover 101 is set on The bottle mouth, the container body 114 includes a container neck 102 , and the container cap 101 is connected to the container neck 102 through a first screw thread 104 . Preferably, a filter including at least two filter layers 105 is arranged in the container neck 102 at the mouth of the bottle, and all the filter layers 105 are arranged at intervals along the axis of the container body 114 , and the edge of the filter is attached to the inner wall of the container neck 102 . In this embodiment, two filter layers 105 are arranged at intervals in the container neck 102 along the axial direction of the container body 114 .

[0029] The drinking water packaging container...

Embodiment 2

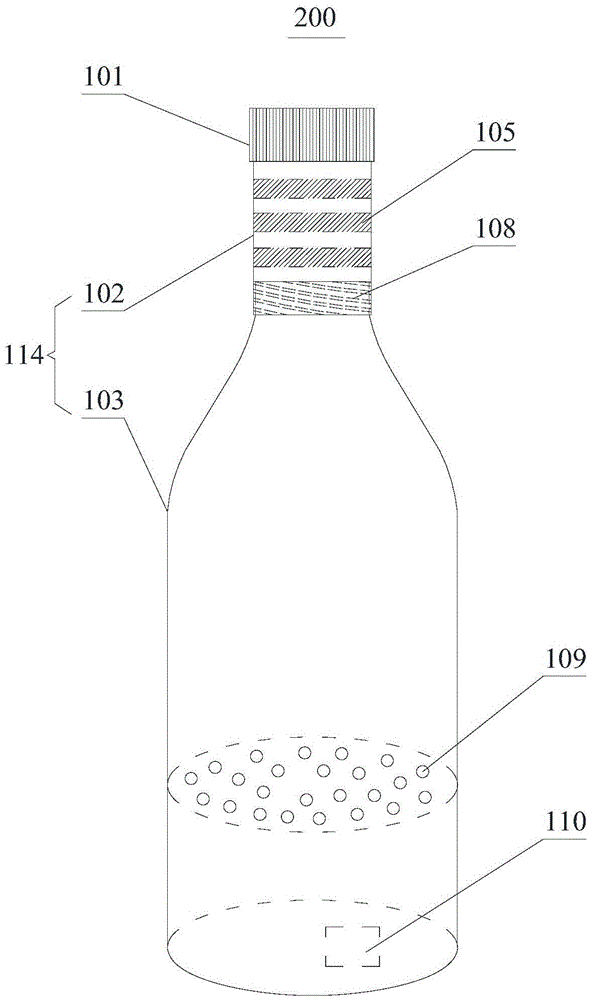

[0038] see image 3 As shown, embodiment 2 provides a kind of drinking water packaging container 200, comprises the container body 114 that has bottle mouth and is used for the container cover 101 of sealing container body 114, and container cover 101 covers and is located at bottle mouth; Bottle mouth place is provided with A filter comprising at least two filter layers 105 , all filter layers 105 are arranged at intervals along the axis of the container body 114 . In the preferred container neck 102 of this embodiment, three filter layers 105 are arranged at intervals along the axis direction of the container body 114: one filter layer 105, two filter layers 105, and three filter layers 105, three different filter layers 105.

[0039] The drinking water packaging container 200 is provided with a filter that can remove pollutants including bacteria, and the container cover 101 is closely connected with the container body 114 to protect the filter. The filter is closely conne...

Embodiment 3

[0045] see Figure 4 As shown, embodiment 3 provides a kind of drinking water packaging container 300, comprises the container body 114 that has bottle mouth and is used for the container cover 101 of sealing container body 114, and container cover 101 covers and is located at bottle mouth; Bottle mouth place is provided with A filter comprising at least two filter layers 105 , all filter layers 105 are arranged at intervals along the axis of the container body 114 . The filter is located outside the container body 114 , the bottom end of the filter is threaded with the bottle mouth, and the top end of the filter is threaded with the container cap 101 . The filter of this embodiment preferably includes two filter layers 105 and two filter bodies 115 that are threaded, each filter layer 105 is located in a filter body 115 respectively, the filter body 115 positioned at the lower floor is threaded with the bottle mouth, and the filter body 115 positioned at the upper floor The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com