Spiral conveying type septic tank cleaning device and septic tank cleaning method

A screw conveying and cleaning device technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of complex equipment price, environmental pollution, large site, etc., and achieve the effect of high dredging efficiency, cheap price and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

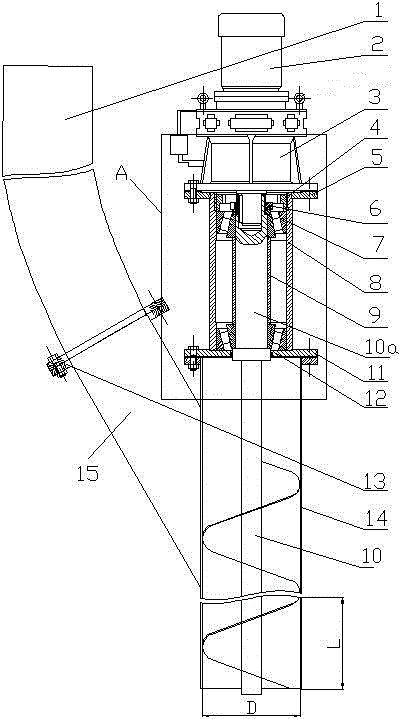

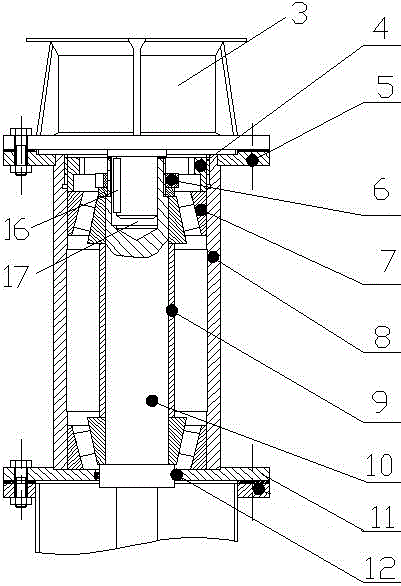

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

[0023] refer to figure 1 and figure 2

[0024] A screw conveying type septic tank cleaning device, comprising a vertically arranged auger outer casing 14, the upper side wall of the auger outer casing communicates with an obliquely upward output pipeline 15, and the auger outer casing is provided with a motor driven mechanism. An auger shaft 10 with helical blades is used to spirally convey the feces and soil accumulated in the septic tank upwards. The included angle 17 between the output pipeline and the outer casing of the auger is 30-50°, so as to facilitate the output of sludge. The delivery pipeline is also connected with a delivery pipeline 1 via a flange 13, so that the soil is sent to the transport v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com