Method for synthesizing slow release type high slump loss resistant polycarboxylate water reducer at normal temperature

A room temperature synthesis, slow-release technology, applied in the field of room temperature synthesis slow-release high-slump polycarboxylate superplasticizers, can solve the problem of low solid content of water reducers and increase the synthesis and sales costs of synthetic polycarboxylate water reducers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

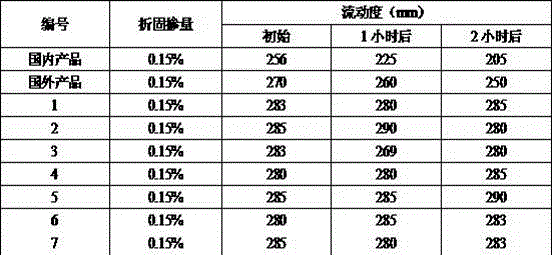

Examples

Embodiment 1

[0039] At 35°C, add 100 parts of isopentenol polyoxyethylene ether macromonomer, 3 parts of maleic anhydride and 77 parts of tap water into the reaction kettle, stir and dissolve into a uniform mixed solution a; dropwise add 5.4 parts of persulfuric acid Mixed solution b made of ammonium and 5.4 parts of hydrogen peroxide; after 10 minutes, add dropwise the mixed solution c made of 3.6 parts of sodium dithionite and 3.6 parts of mercaptopropionic acid; The mixed solution d made of sodium bicarbonate, the dropping time is 1.5h; after the dropping, keep warm for 2.5h to end the reaction; use NaOH solution to adjust the pH value to 6, and the obtained light yellow transparent liquid is polycarboxylate superplasticizer.

Embodiment 2

[0041] At 30°C, add 100 parts of isopentenol polyoxyethylene ether macromonomer, 4 parts of maleic anhydride and 76 parts of tap water into the reaction kettle, stir and dissolve into a uniform mixed solution a; dropwise add 5.4 parts of persulfuric acid Mixed solution b made of ammonium and 16.2 parts of hydrogen peroxide; after 10 minutes, add dropwise the mixed solution c made of 4 parts of sodium dithionite and 6 parts of mercaptopropionic acid; The mixed solution d made of sodium bicarbonate, the dropping time is 2 hours; after the dropping, keep warm for 2 hours to end the reaction; adjust the pH value to 6.5 with NaOH solution, and the obtained light yellow transparent liquid is polycarboxylate superplasticizer.

Embodiment 3

[0043] At 25°C, add 100 parts of isopentenol polyoxyethylene ether macromonomer, 5 parts of maleic anhydride and 75 parts of tap water into the reaction kettle, stir and dissolve to form a uniform mixed solution a; dropwise add 6 parts of persulfuric acid Mixed solution b made of ammonium and 12 parts of hydrogen peroxide; 10 minutes later, add dropwise the mixed solution c made of 6 parts of sodium dithionite and 12 parts of mercaptopropionic acid; The mixed solution d made of sodium bicarbonate, the dropping time is 2h; after the dropping, keep warm for 2.5h to end the reaction; use NaOH solution to adjust the pH value to 7, and the obtained light yellow transparent liquid is polycarboxylate superplasticizer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap