A screw propulsion external heating type coal dry distillation device

A technology of screw propulsion and screw conveying device, which is applied in the direction of charging device, special dry distillation, coke oven with mechanical device transportation, etc., can solve the problem of low dust content of raw coal gas, avoid complex equipment structure and realize cycle Utilization, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

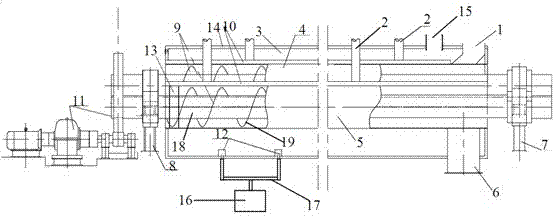

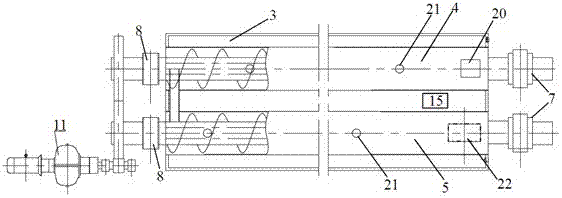

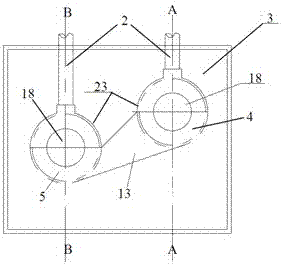

[0048] Attached below Figure 8 to attach Figure 11 The specific composition structure and working process of the second preferred embodiment of the spiral propulsion external heating type coal carbonization device of the present invention are given. as attached Figure 8 to attach Figure 11 As shown, the difference between the second preferred embodiment of the screw propulsion external heating type coal pyrolysis device of the present invention and the above-mentioned first preferred embodiment is only that, in the second preferred embodiment, the front bearing support 7 It is installed inside the heating chamber 3. Specifically, the rear ends of the cylinders of the upper carbonization chamber 4 and the lower carbonization chamber 5 are sealed and fixed on the rear end surface of the heating chamber, and the front ends of the cylinders of the upper carbonization chamber 4 and the lower carbonization chamber 5 are located inside the heating chamber. , and the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com