Mold capable of weaving plane oblique-crossing woven fabric of any angle and gap

A technology of weaving cloth at any angle, which is applied in the direction of braided fabrics, hand-woven fabrics, textiles, and papermaking. It can solve the problems of high production cost, long cycle, and constraints of plane bias composite fiber cloth, and achieve simple use and fast cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] combine Figure 1 to Figure 4 Specific embodiments of the present invention will be described.

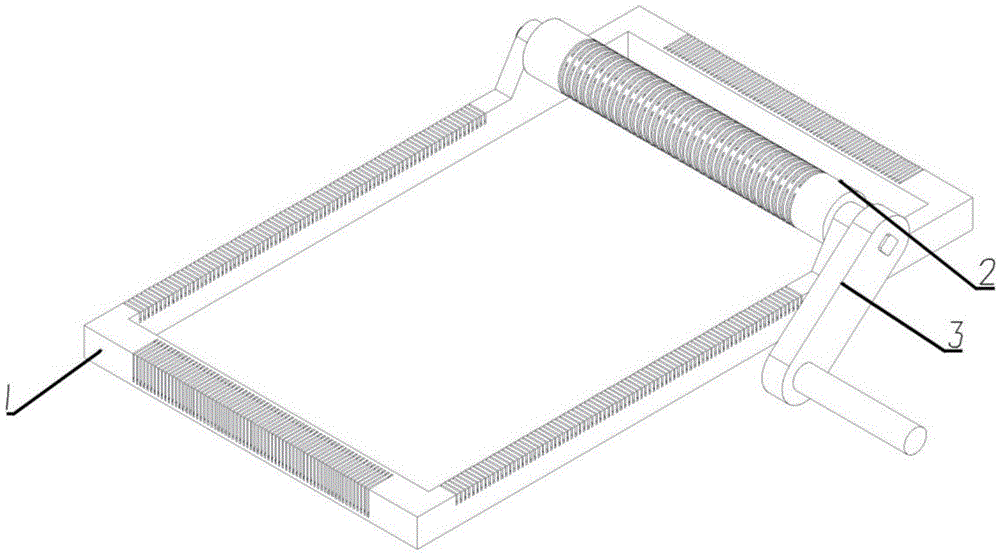

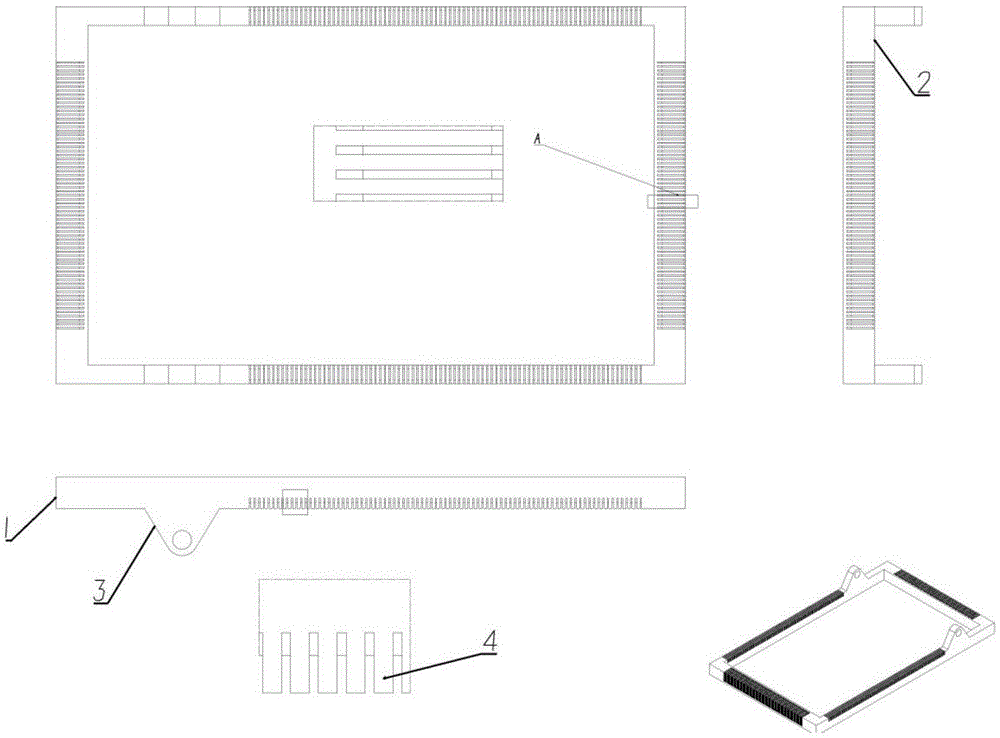

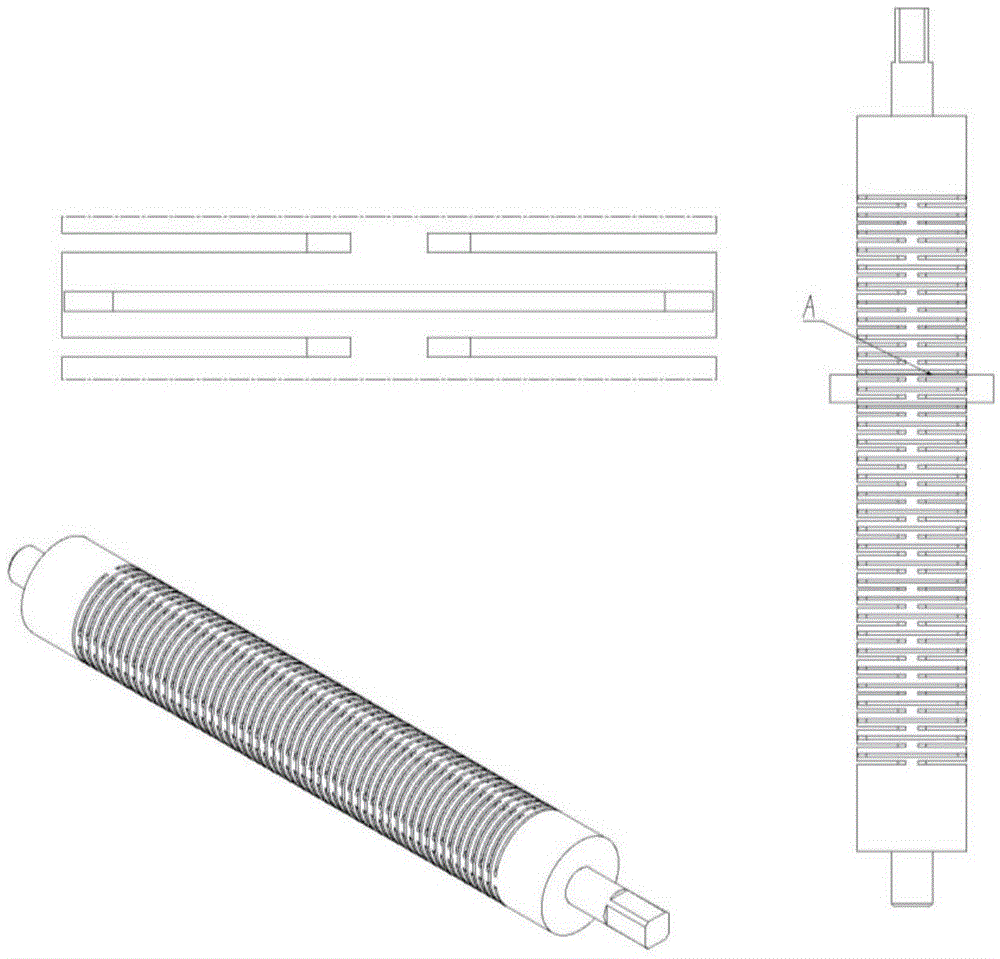

[0024] figure 1 It is a mold for weaving plane bias weaving cloth at any angle and gap. It is composed of a metal frame with grooves, a warp fiber bundle splitting shaft, and a splitting shaft crank. The positional connection relationship between them is: fiber The beam splitting shaft is placed on the grooved metal frame in parallel, and is connected with the frame by a reinforcing rib, and the crank of the splitting shaft is connected with the boss of the warp fiber bundle splitting shaft.

[0025] The working principle is as follows: rotate the warp fiber bundle splitting shaft to displace the warp in space, and divide the warp yarns into upper and lower layers according to odd and even numbers, so that there is a large gap between the two layers. Use the splitting shaft crank Rotate, intersperse two adjacent warps in the same direction with only one weft bundle in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com