Method for dyeing regenerated cellulose fibers through isatis root natural dyestuff and application of method to mask

A technology of regenerated cellulose and natural dyes, applied in the field of fiber dyeing, can solve the problems of high dimensional change rate of finished products, low color fixation rate, low dyeing rate, etc. The effect of less waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

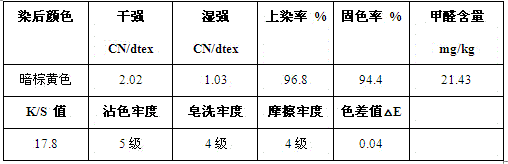

Embodiment 1

[0052] Example 1 A method of dyeing regenerated cellulose fibers (viscose fibers) using Radix Radix natural dyes

[0053] (1) Cleaning, drying and crushing of Radix isatidis raw materials

[0054] Take Radix Isatidis (the dried root of the cruciferous plant Isatis indigo), ultrasonically clean it at 20KHZ for 2 minutes at room temperature, then clean it with 40KHZ ultrasonically for 1 minute, air-dry at low temperature, and perform jet milling. The condition of jet milling is set as follows: The pressure is 1.2MPa; the screw feeding speed is 22HZ; the frequency of the classifier motor is set to 12HZ, and the particle size of the crushed material is crushed to 100 mesh to obtain Radix isatidis powder.

[0055] (2) Ultrasonic-assisted subcritical extraction of Radix isatidis dye

[0056] Take Radix isatidis powder, choose ethanol with a concentration of 65% as a solvent, ultrasonic power is 1200w, and ultrasonic frequency is 51-60KHz. The mass ratio of Radix isatidis powder to...

Embodiment 2

[0108] Example 2 A method of dyeing regenerated cellulose fibers (modal fibers) using Radix isatidis natural dyes

[0109] (1) Cleaning, drying and crushing of Radix isatidis raw materials

[0110] Take Radix Isatidis (the dried root of the cruciferous plant Isatis indigo), and use 10KHZ ultrasonic cleaning for 2 minutes at room temperature, then use 20KHZ ultrasonic cleaning for 5 minutes, air-dry at low temperature, and perform jet milling. The condition of jet milling is set as: air storage tank The pressure is 1.5MPa; the screw feeding speed is 30HZ; the frequency of the classifier motor is set to 20HZ, and the particle size of the crushed material is crushed to 200 mesh to obtain Radix isatidis powder.

[0111] (2) Ultrasonic-assisted subcritical extraction of Radix isatidis dye

[0112] Take Radix isatidis powder, choose ethanol with a concentration of 70% as solvent, ultrasonic power is 1500w, ultrasonic frequency is 60KHz. The mass ratio of Radix isatidis powder to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap