An anti-seepage outer wall thermal insulation decorative finished board

A technology for exterior wall insulation and finished products, applied in insulation, building insulation materials, floors, etc., can solve problems such as loss of waterproofing effect, difficulty in filling and dense filling, and different gap widths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

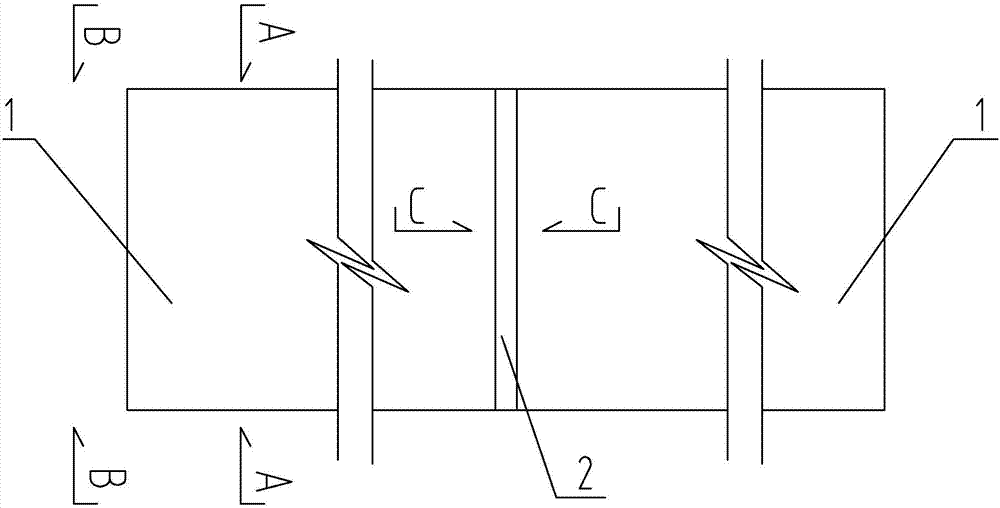

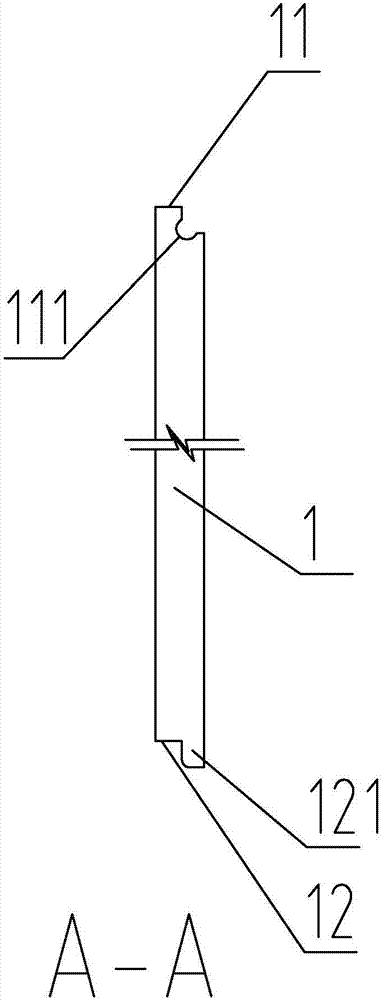

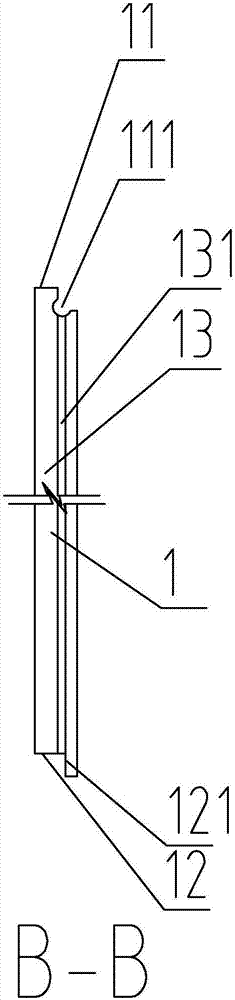

[0025] Refer to attached Figure 1 to Figure 8 A further detailed description will be made on the finished board for thermal insulation and decoration of an anti-seepage external wall of the present invention.

[0026] An anti-seepage exterior wall thermal insulation decoration finished board, comprising several exterior wall thermal insulation decoration finished board main bodies, each top edge 11 of the exterior wall thermal insulation decoration finished board main body 1 is provided with an inwardly recessed notch 111, the outer wall thermal insulation The bottom edge 12 of the main body 1 of the finished decorative board is provided with a protruding head 121, wherein the notch 111 of the main body 1 of the finished board body 1 for thermal insulation and decoration of the external wall is in contact with the convex head 121 of the main body 1 of the finished board body 1 of the finished board body for thermal insulation and decoration of the outer wall. Fastening; there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com