An Adaptive Coring Inner Tube

An self-adaptive, inner tube technology, applied in the direction of extracting undisturbed core devices, earthwork drilling, etc., can solve the problems of increasing drilling costs, reducing coring efficiency, and reducing work efficiency, so as to reduce drilling costs and increase recovery rate , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

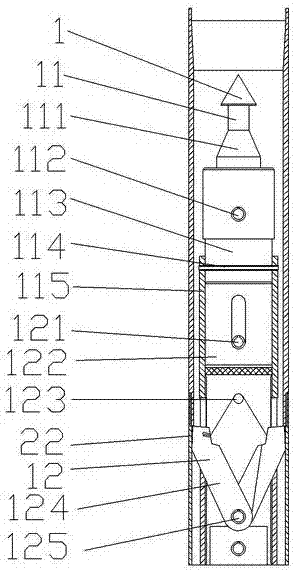

[0023] see figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention is composed of an inner tube mechanism 1 and an outer tube mechanism 2, and the inner tube mechanism 1 is arranged in the outer tube mechanism 2;

[0024] The inner pipe mechanism 1 includes a salvage mechanism 11, a cartridge positioning mechanism 12, a suspension mechanism 13, a single-action mechanism 14, an adjustment mechanism 15, a compound coring mechanism 16 and an inner pipe 17, a salvage mechanism 11, a cartridge positioning mechanism 12, a suspension mechanism 13. The single-action mechanism 14, the adjustment mechanism 15, the compound coring mechanism 16 and the inner tube 17 are sequentially arranged in the outer tube mechanism 2;

[0025] The fishing mechanism 11 includes a spearhead 111, a positioning pin 112, a cone shaft 113, a first elastic cylindrical pin 114 and an upper recovery pipe 115. The spearhead 111 is hinged to the cone shaft 113 through the positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com