Tunnel inverted-arch self-propelled trestle

A self-propelled, tunnel-based technology, applied in tunnels, tunnel linings, pedestrian bridges, etc., can solve problems affecting construction progress, high procurement costs, and excessive raw materials, and achieve the effects of reducing construction accidents, ensuring construction progress, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

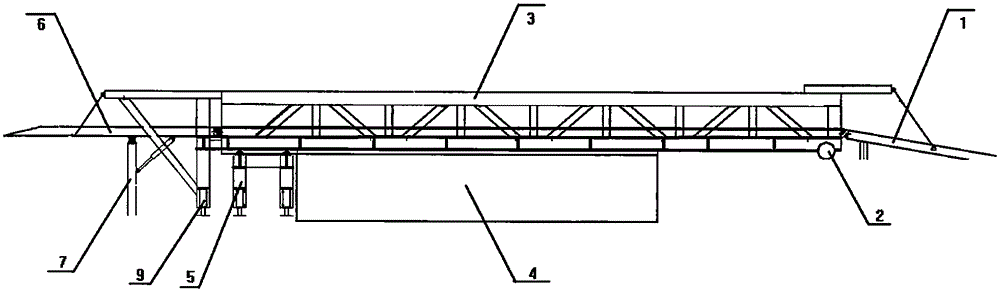

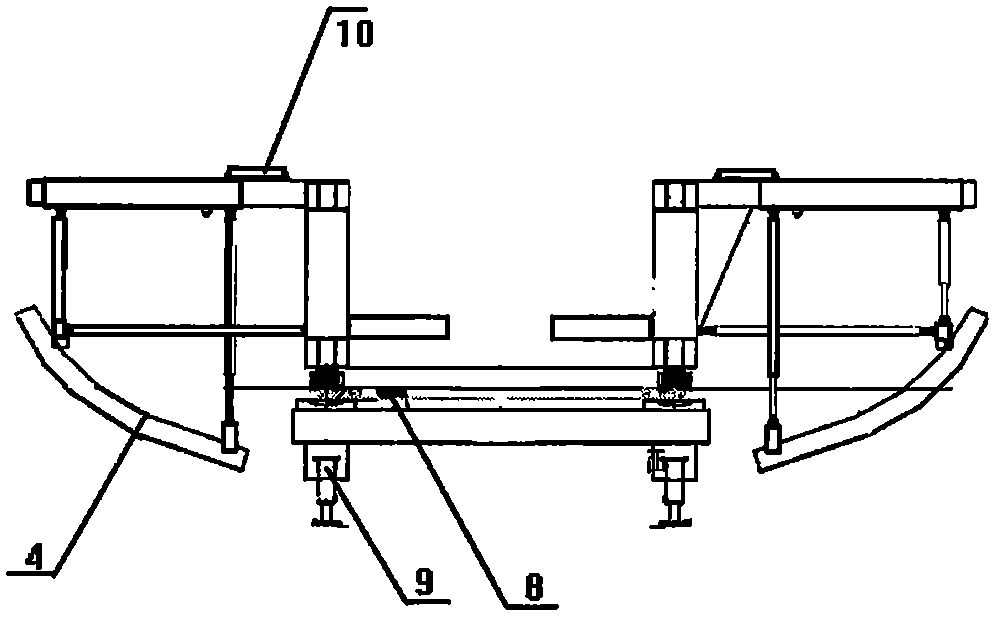

[0014] As shown in the figure, a tunnel inverted arch self-propelled trestle is composed of a rear approach bridge (1), a driving wheel (2), a bridge body (3), a side form system (4), a walking support (5), and a front approach bridge (6). ), the front axle support (7), the integral translation oil cylinder (8), the foundation oil cylinder (9), and the formwork mobile oil cylinder (10) constitute;

[0015] The rear approach bridge (1) is arranged at the rear of the bridge body (3), the driving wheel (2) is arranged under the rear end of the bridge body (3), and the walking support (5) is arranged under the bridge body (3), The front approach bridge (6) is arranged in front of the bridge body (3), the front bridge support (7) is arranged under the front approach bridge (6), and the overall translation oil cylinder (8) is arranged under the front end of the bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com