Full power speed increasing impeller and frame system

A full-power, impeller technology, applied in wind power generation, wind engines, machines/engines, etc., to achieve the effects of improving operating characteristics, good stability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

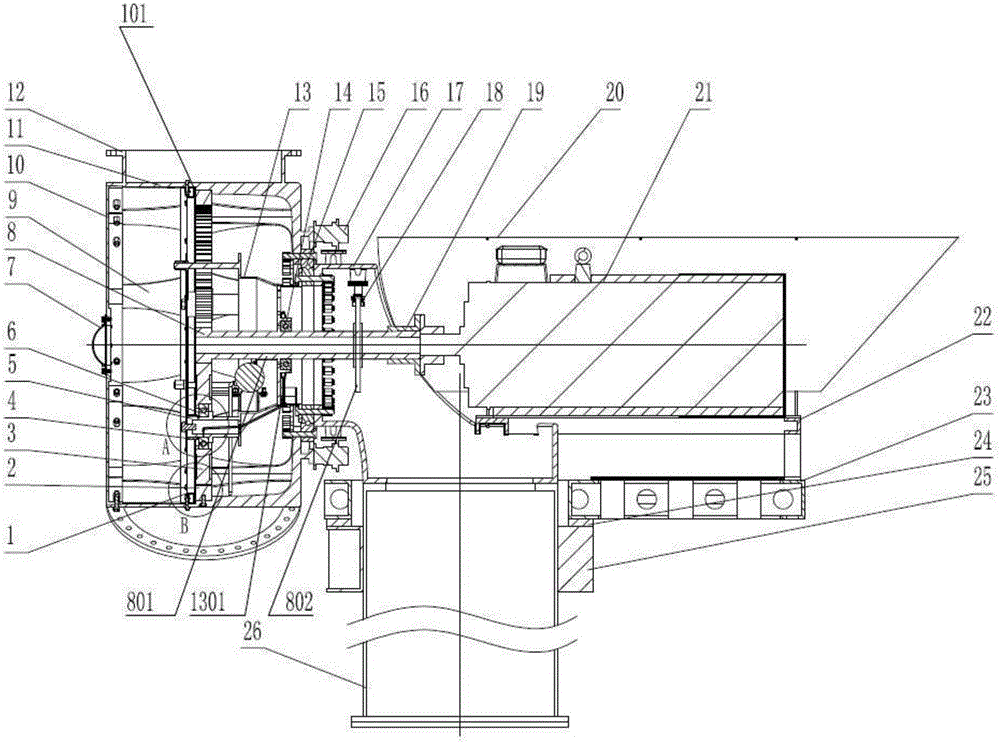

[0048] Such as figure 1 As shown, the full-power speed-up impeller and frame system is composed of the impeller speed-up system, the generator 21 and the frame system. into electrical energy system output;

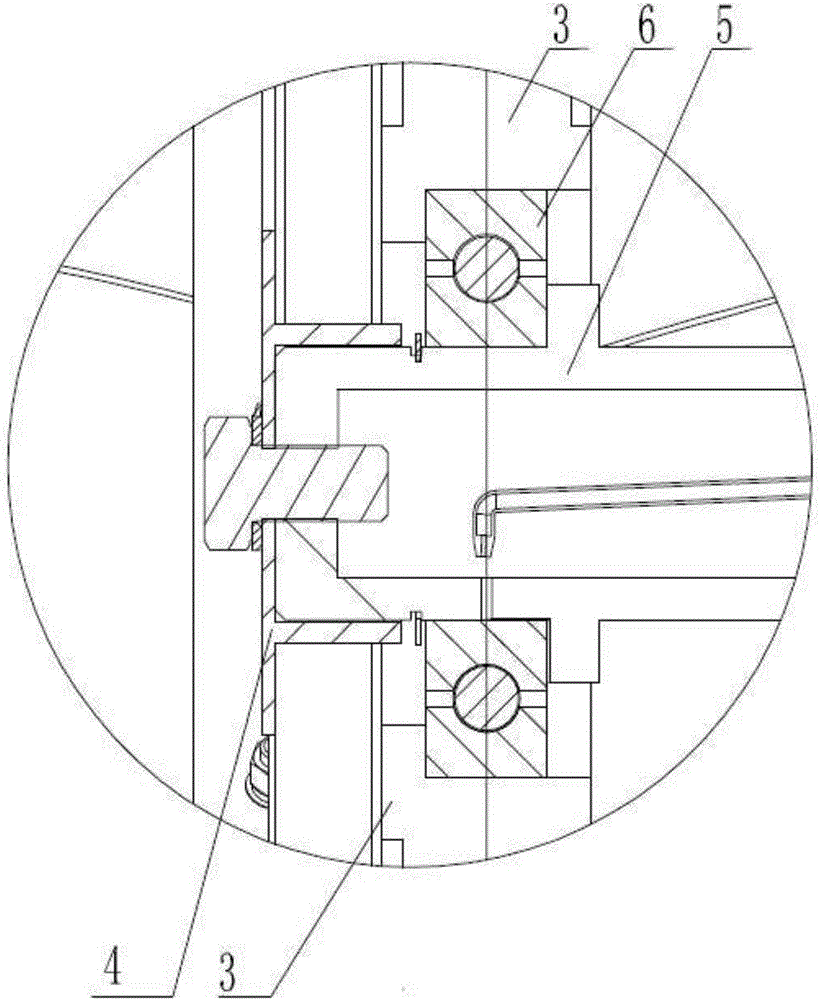

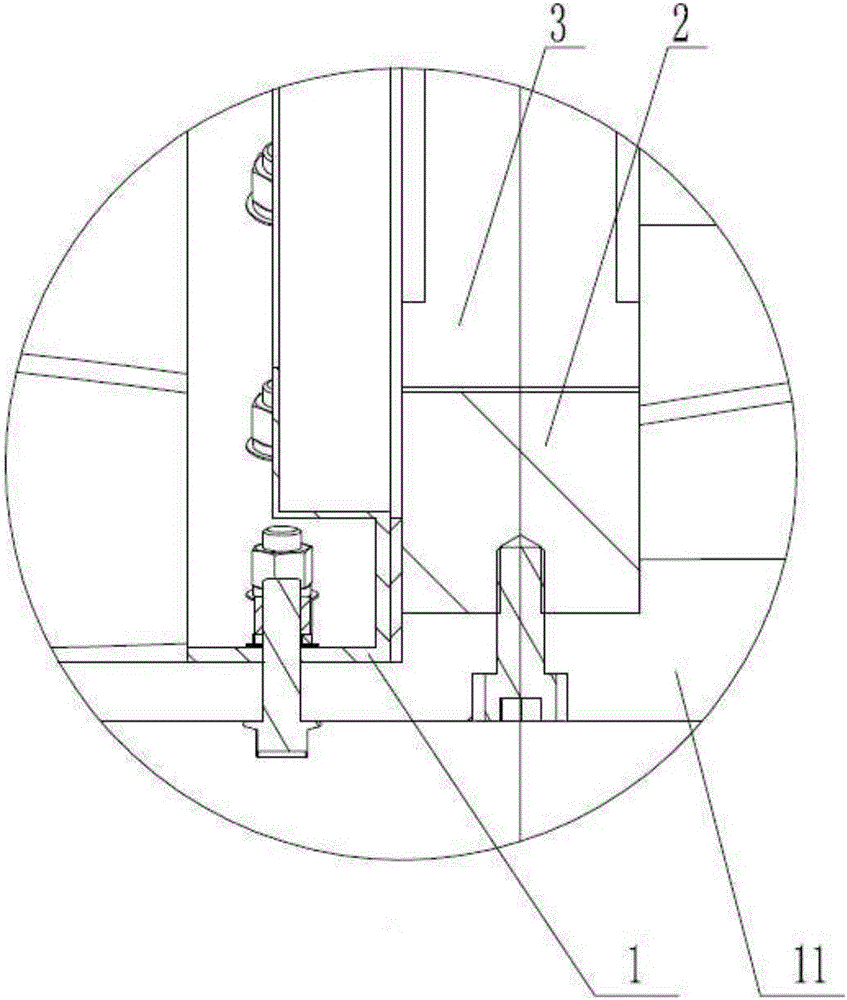

[0049] Such as figure 1 , figure 2 , image 3 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, the specific structure of the impeller speed increasing system is as follows: including the impeller cylinder 11, a plurality of blade bases 12 for connecting the blades are evenly distributed on the outer wall of the impeller cylinder 11, and the ring gear 2 is fixed on the inner wall of the impeller cylinder 11 , a plurality of planetary gears 3 are meshed on the inner ring of the ring gear 2. In this embodiment, there are three planetary gears 3, each planetary gear 3 is meshed with the sun gear 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com