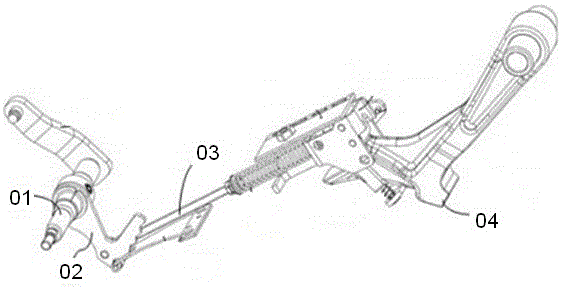

a parking mechanism

A parking mechanism and parking technology, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of cumbersome assembly process, failure of parking mechanism, and long tie rods of cockscomb teeth, etc. Design space, stable work, easy layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

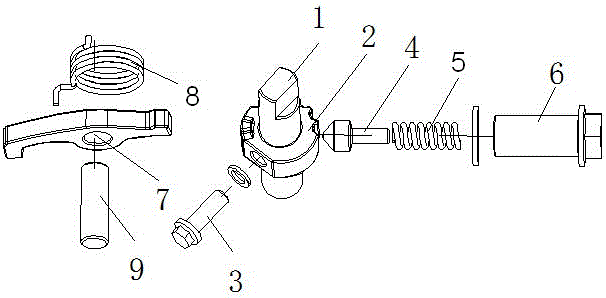

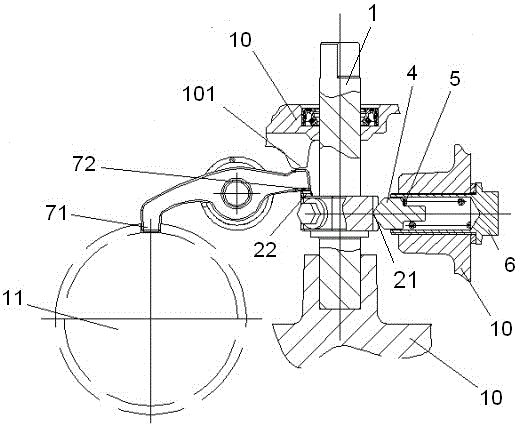

[0027] A parking mechanism disclosed in the present invention includes: a gearbox case 10 , a shift shaft 1 , a gear switch 2 , a shift positioning pin 4 , a parking arm 7 and a parking gear 11 .

[0028] The gear shift shaft 1, the gear switch platform 2, the gear shift positioning pin 4, the parking arm 7 and the parking gear 11 are placed in the gearbox case 10.

[0029] The gear shifting platform 2 is set and fixed on the shift shaft 1, specifically, a bolt 3 can pass through the side wall of the gear switching platform 2 and be fixed on the shaft body of the gear shifting shaft 1.

[0030] The side wall of the gear switching platform 2 is provided with a gear slot 21, and the gear slot 21 includes a parking gear slot; the gear positioning pin 4 is telescopic against the gear slot 21; The pin body is covered with a spring 5 and is inserted into a hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com