A planar rigid frame loading experimental device

A technology for loading experiments and rigid frames, which is used in measuring devices, instruments, scientific instruments, etc. It can solve the problems that the rigid frame cannot be used for experiments, and the loading and supporting forms of changing the rigid frame are troublesome, so as to achieve compact structure, small weight and light weight. , to ensure the effect of lateral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

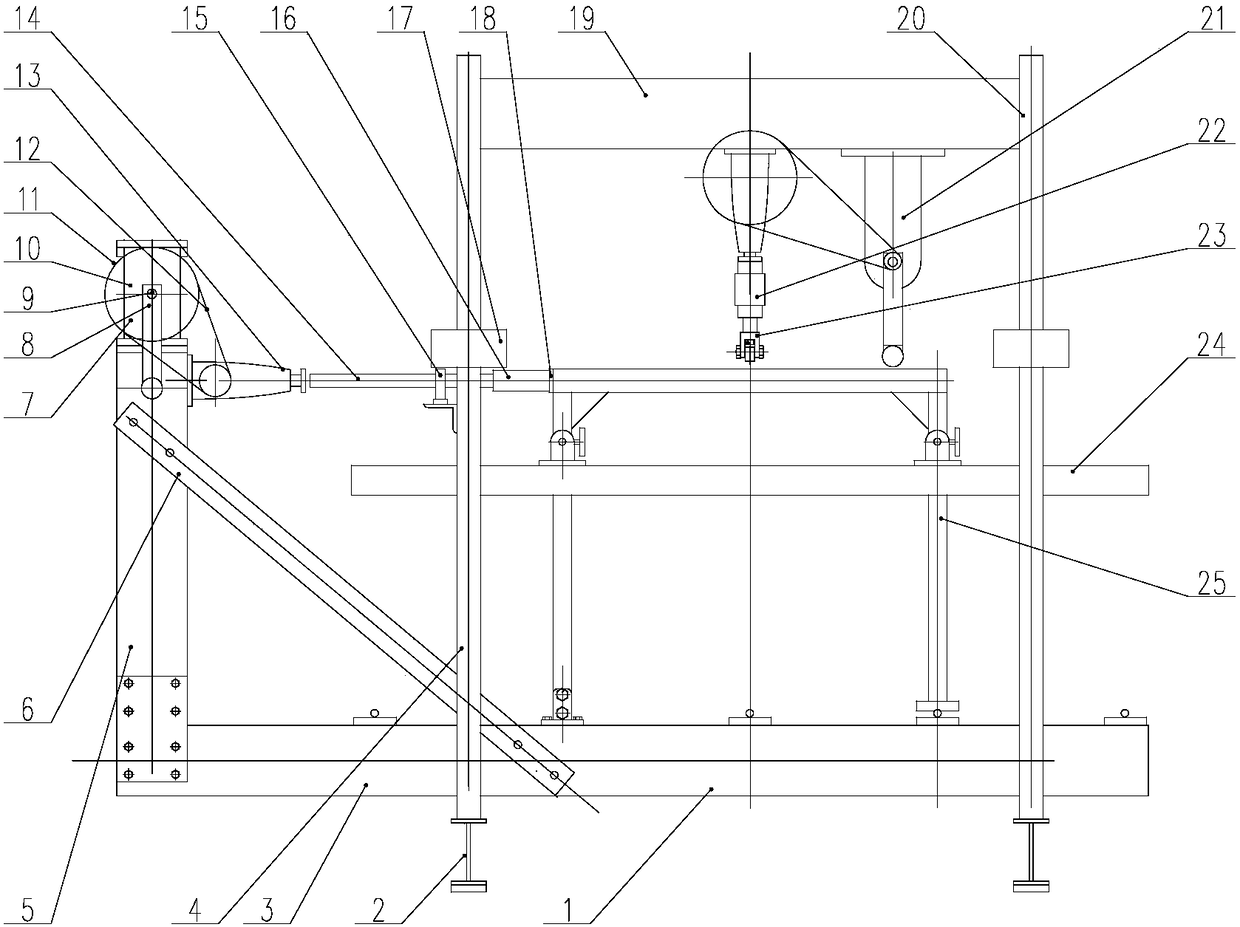

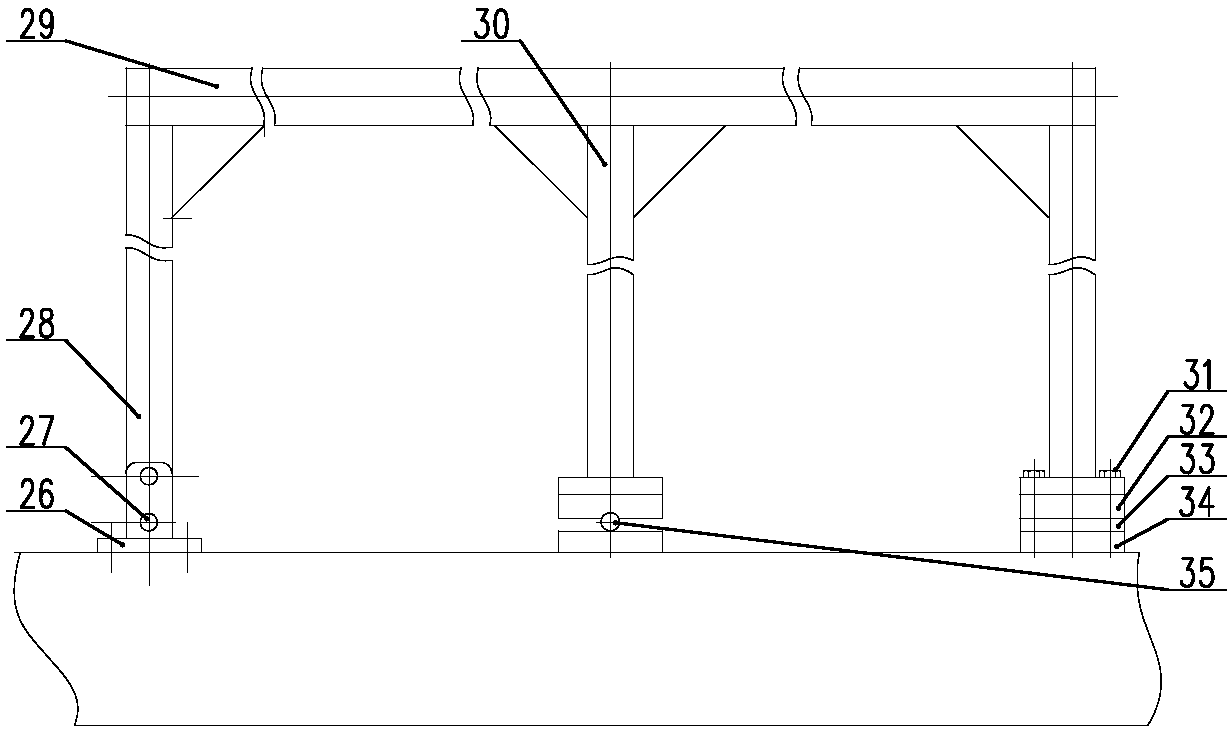

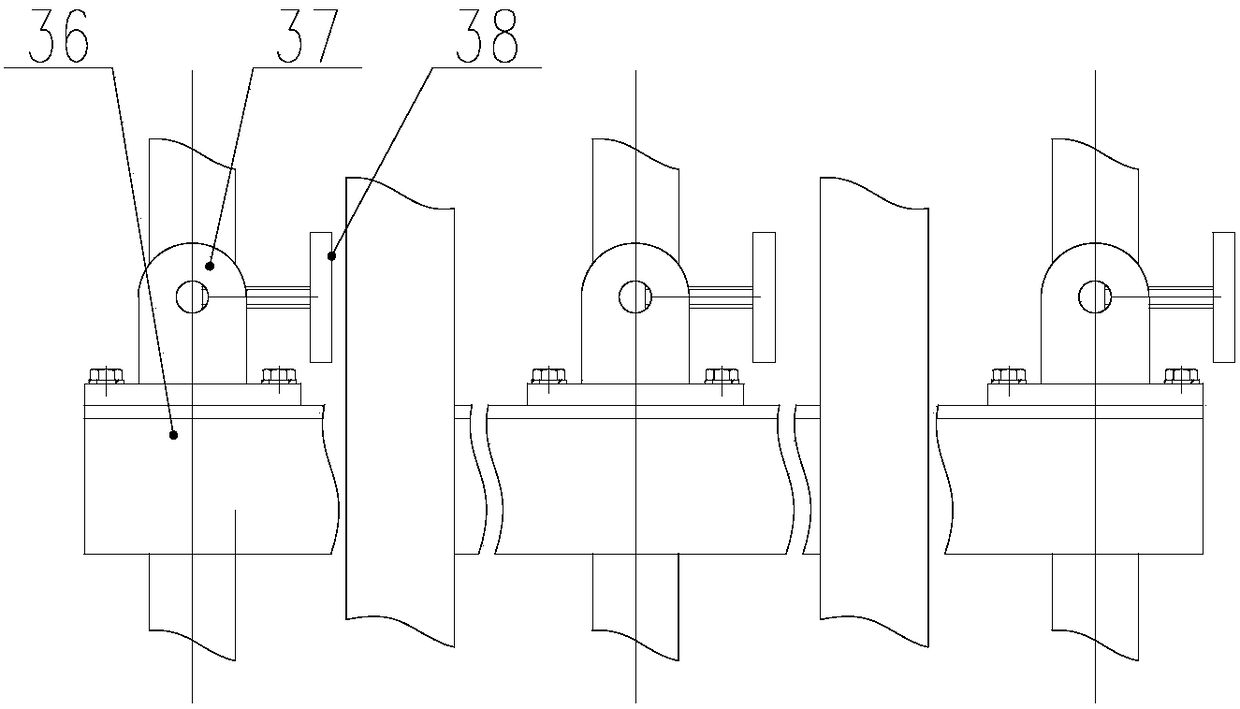

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 A plane rigid frame loading experimental device shown includes: frame 1, rigid frame and support assembly 25, lateral restraint assembly 24, vertical loading device 21, vertical force measuring device 22, vertical indenter assembly 23 and lateral loading force measuring device 7;

[0036] The frame 1 includes: a base 2, a lower beam 3, an upper beam 19, a left column 4, a right column 20, a side beam 5 and a side beam tie rod 6;

[0037] Wherein, the lower beam 3, the upper beam 19, the left column 4 and the right column 20 together form a rectangular frame structure, and both ends of the lower beam 3 protrude from the outside of the left column 4 and the right column 20;

[0038] The side beam 5 is fixed to the protruding end of one side of the lower cross beam 3;

[0039] The side beam tie rod 6 is obliquely fixed on the side beam 5 and the lower beam 3, and the side beam tie rod 6, the side beam 5 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com