Magnetic Barkhausen and magnetic parameter sensor and measurement method of magnetic Barkhausen and magnetic parameter

A magnetic parameter and sensor technology, applied in the field of material detection, can solve the problems of reduced detection efficiency, inability to comprehensively evaluate the state of metal materials, lack of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

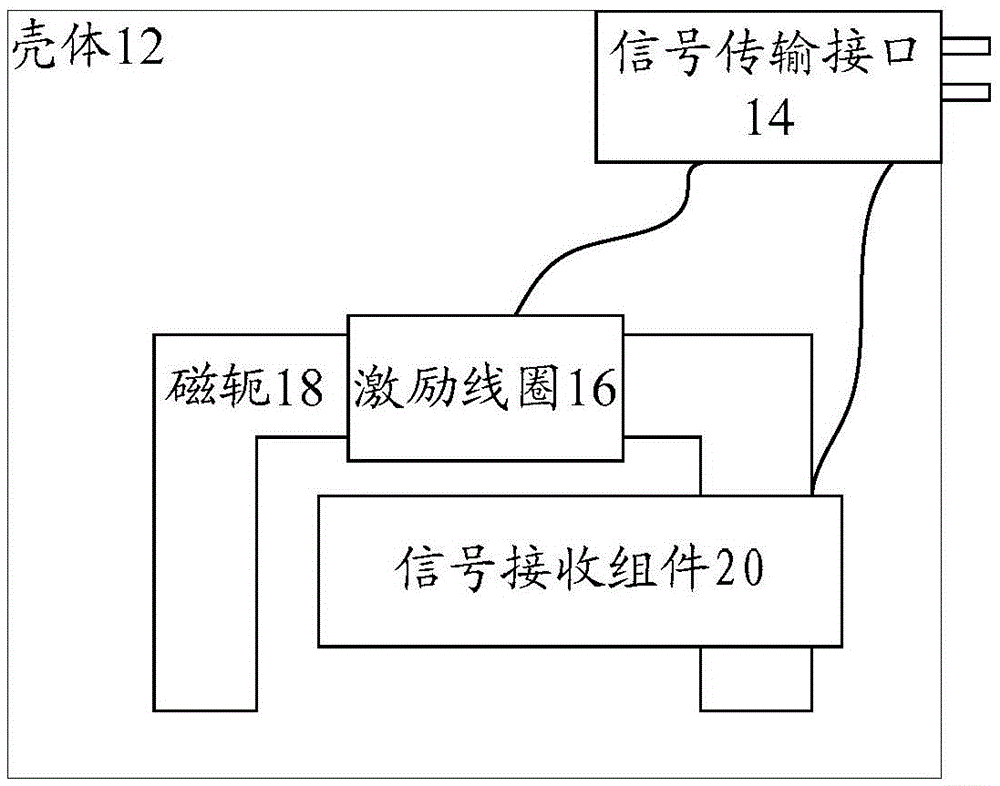

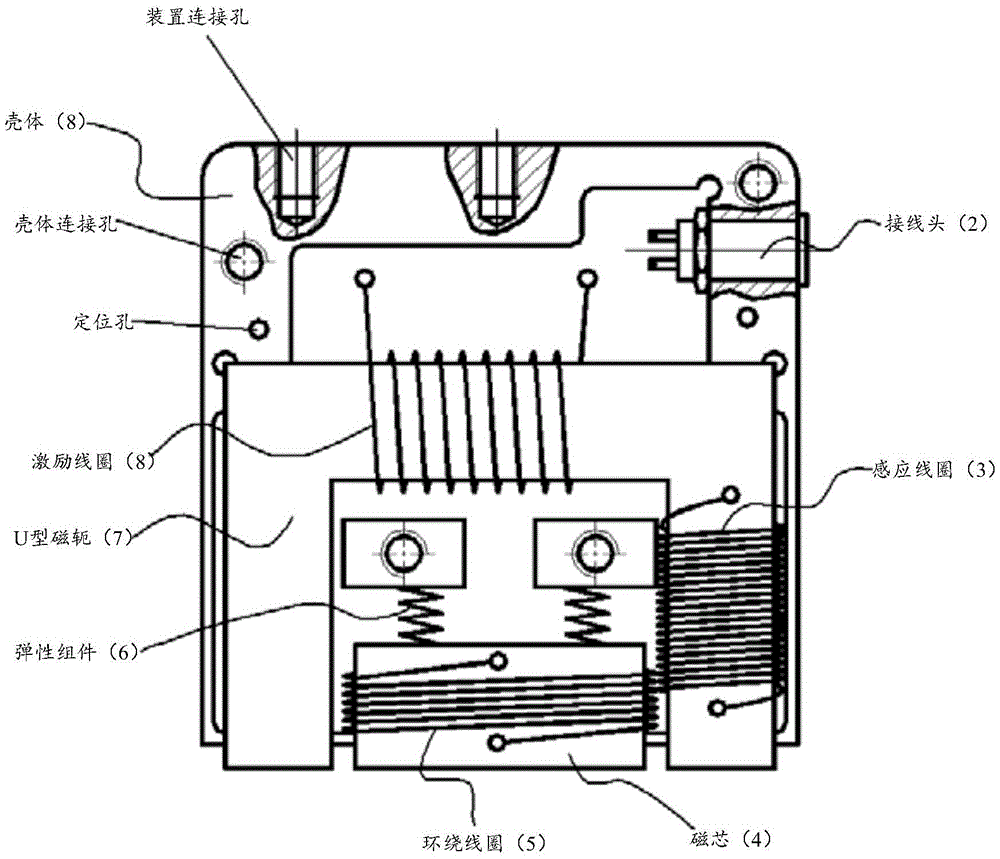

[0018] According to an embodiment of the present invention, a device embodiment of a magnetic Barkhausen and a magnetic parameter sensor is provided, figure 1 It is a structural schematic diagram of a magnetic Barkhausen and a magnetic parameter sensor according to an embodiment of the present invention, such as figure 1 As shown, the device includes: a housing 12, a signal transmission interface 14, an excitation coil 16, a yoke 18 and a signal receiving assembly 20, wherein,

[0019] The signal transmission interface 14 is electrically connected with the excitation coil 16 and the signal receiving assembly 20, and is used to transmit the excitation signal to the excitation coil 16 and receive the feedback signal returned by the signal receiving assembly 20, wherein the signal receiving assembly 20 includes: a magnetic parameter measurement assembly and Barkhausen signal measurement components;

[0020] The excitation coil 16 is wound around one end of the yoke 18, and is us...

Embodiment 2

[0055] According to an embodiment of the present invention, a method embodiment of a method for measuring magnetic Barkhausen and magnetic parameters is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a set of computer-executable instructions such as and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0056] Figure 5 It is a schematic flow chart of a measurement method for measuring magnetic Barkhausen and magnetic parameters according to an embodiment of the present invention, such as Figure 5 shown, applied to Figure 1 to Figure 4 In the shown sensor for measuring magnetic Barkhausen and magnetic parameters, the measuring method comprises the following steps:

[0057] Step S502, inputting an excitation signal through a signal transmission interface;

[0058]Step S504, triggerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com