Anti-short circuit transformer coil and preparation method thereof

A transformer coil and anti-short circuit technology, which is applied in the field of transformers, can solve the problems of excessive impedance change, poor rigidity, and increased distance of the main channel, and achieve the effect of close cost, simple and effective method, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

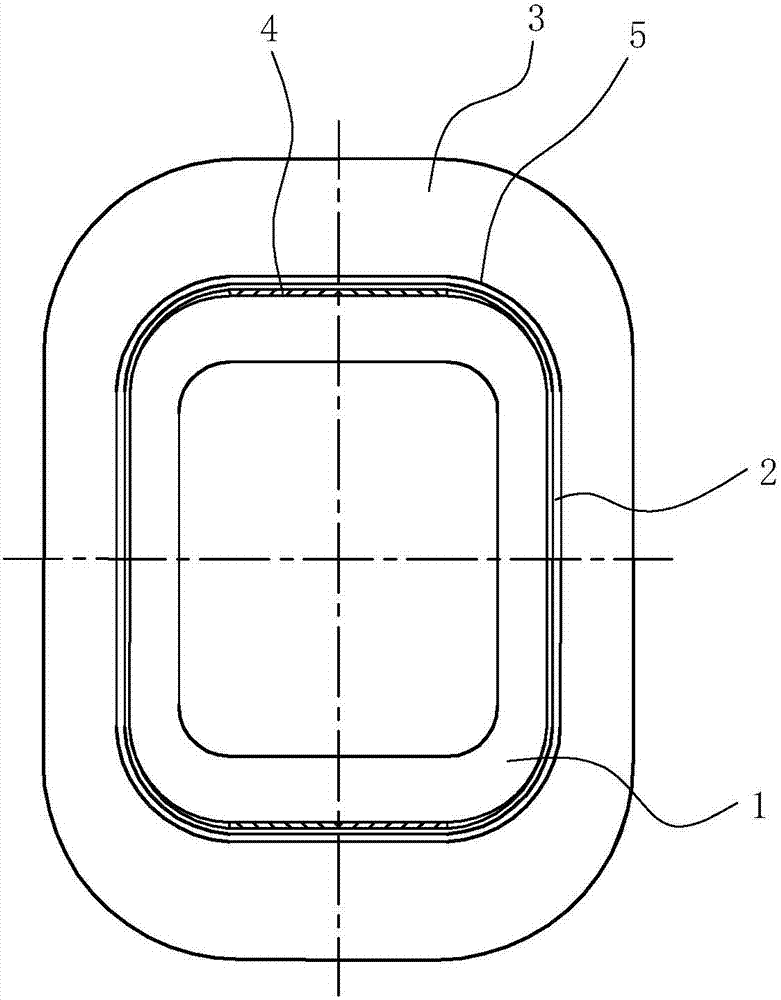

[0026] The embodiment of the present invention can be made as figure 1 The one-way transformer shown can also be made into a three-phase transformer, and the one-way transformer is taken as an example to illustrate. It includes a low-voltage coil 1, a main channel insulation 2 and a high-voltage coil 3 arranged sequentially from the inside to the outside, wherein a reinforcing material 4 is arranged between one of the adjacent layers of the last few layers of windings of the low-voltage coil. In this embodiment , the low-voltage coil 1 is a foil coil, the number of layers of the last few layers of windings of the low-voltage coil ranges from the last 2 layers to the last 5 layers, and the reinforcement material 4 is steel plate, epoxy resin plate or glass steel plate, and the reinforcement The material 4 is located at the straight line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com