Remote manual product quality detection method based on mobile terminals

A mobile terminal, product quality technology, applied in the direction of measurement devices, transmission systems, resources, etc., can solve the problems of harsh production environment, inability to transmit, reduce work efficiency, etc., to reduce the possibility of intentional or unintentional interference and errors, The effect of enhancing credibility and improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

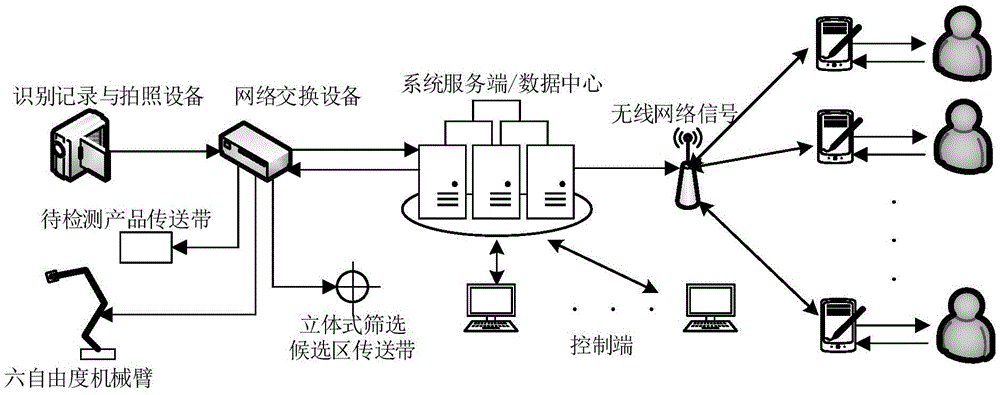

[0024] The scene of the embodiment of the present invention is based on the sorting machine outputting the goods, the goods are conveyed on the conveyor belt and can be operated by the robotic arm, but the present invention is not limited to this scene, and other production environments are also applicable.

[0025] see figure 1 After the product is output from the sorting machine (not shown in the figure), it enters the product conveyor belt to be detected. There is an infrared sensing device (not shown in the figure) near the predetermined position of the conveyor belt. When the product on the conveyor belt passes through this position , the infrared sensing device can sense the product, and there are n sets of identification recording and photographing equipment around the predetermined position, and the n sets of identification recording and photographing equipment are arranged in different positions so that they can reach the predetermined position Shooting from different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com