Metal-plastic sandwich sheet and method for the production thereof

A technology of plastic clips and metal plates, applied in metal layered products, chemical instruments and methods, lamination, etc., can solve problems such as cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

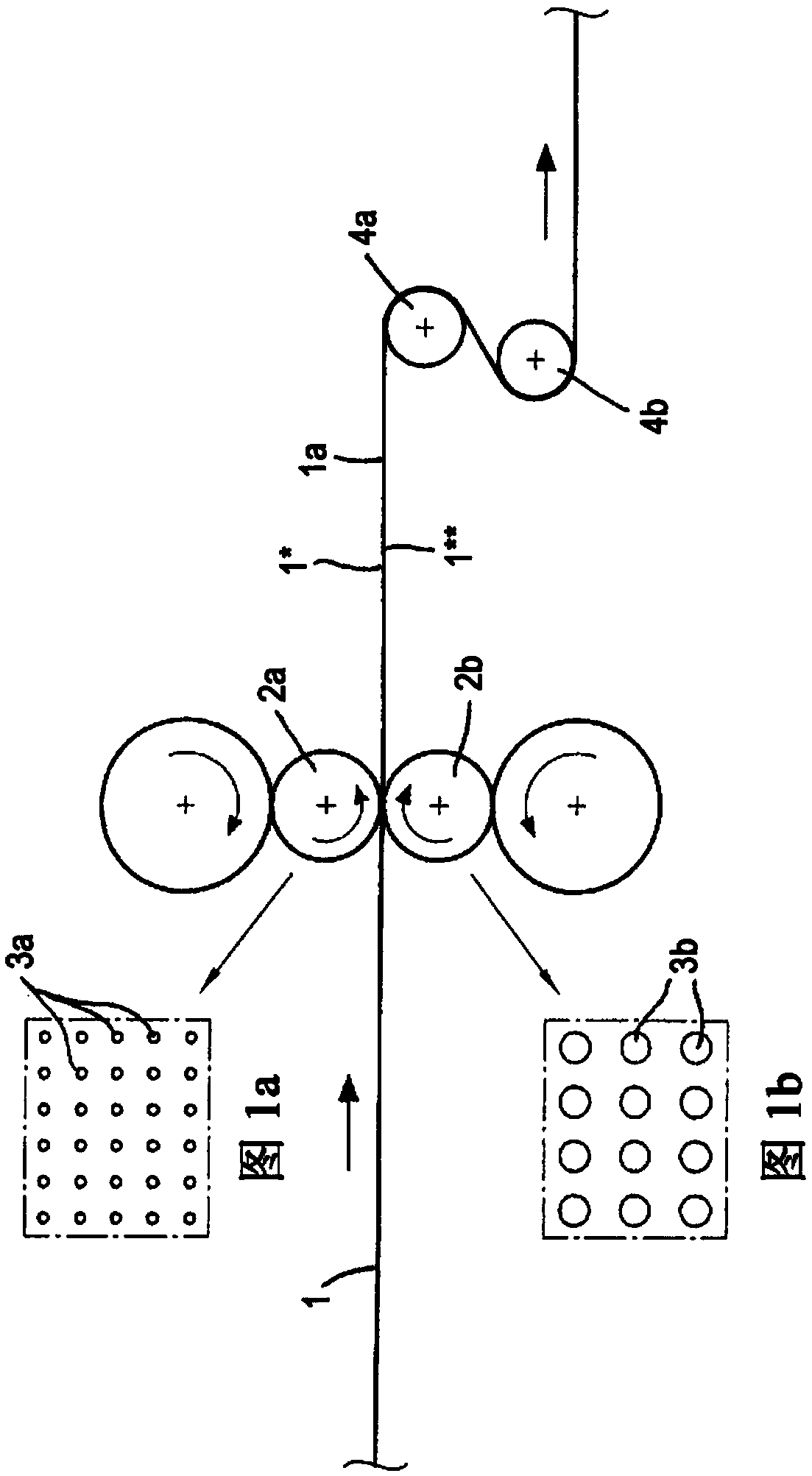

[0042] exist figure 1A device for flattening strip-shaped metal sheets 1 is shown. The metal sheet 1 is preferably a steel sheet, eg having a thickness in the range of 0.1 to 0.5 mm. The plant comprises a rolling stand with temper rolls 2a, 2b defining a rolling gap substantially smaller than the thickness of the strip 1 to be tempered. By flattening, a defined roughness is formed or adjusted on the individual sides of the metal strip 1 . Each of the two temper rolls 2a, 2b has a specific surface structure for this purpose.

[0043] According to the invention, for the levelling of the metal strip 1, levelling rolls 2a, 2b with surface structures of different degrees of roughness are used. For example, the upper temper roll 2a has a relatively flat surface structure, while the lower temper roll 2b has a relatively rough surface structure. this is in figure 1 a and figure 1 Schematically shown in b on an enlarged scale in surface sections of the temper rolls 2a, 2b, repres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com