Multilayer polymeric sheets and light weight laminates produced therefrom

A technology of polymer sheets and laminates, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of low penetration resistance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

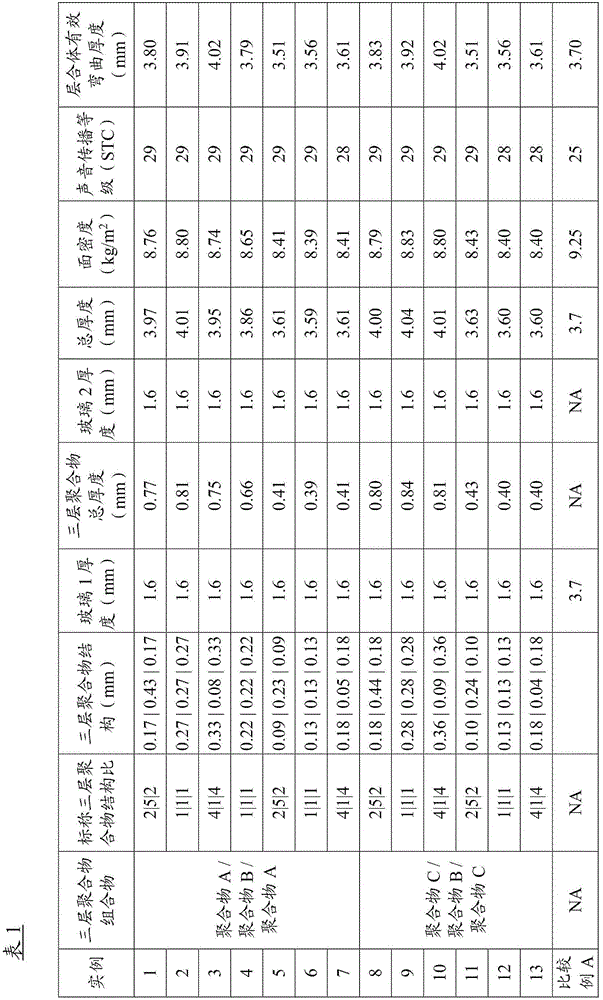

example 1 to 13 and comparative example A

[0100] Thirteen (13) laminates were prepared according to the standard lamination procedure shown above, numbered examples 1-13. A three-layer sandwich sheet is prepared according to the standard extrusion method described above, which has an outer layer of ternary ionomer (polymer A) or ionomer (polymer C) and an inner layer of EVA (polymer B). More specifically, polymer C is a neutralized product of a dimer.

[0101] The thickness of the individual layers, as well as the overall thickness of the multilayer sheet and the nominal three-layer polymer structure ratio are shown in Table 1. A micrometer with a flat measuring head is used to measure the overall thickness of the three-layer sheet. The thickness of the entire sheet was measured in three positions (left, center, and right), and the average of the three thickness measurements is recorded in Table 1.

[0102] Calculate the thickness of the inner and outer layers of the three-layer sheet based on the feed ratio of the incom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com