Apparatus for loading onto loading areas

A technology of a loader and a loading device, applied in the field of loader, can solve the problems of not being successful in the market, and achieve the effects of simple lifting adjustment, durable structure, and accurate stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

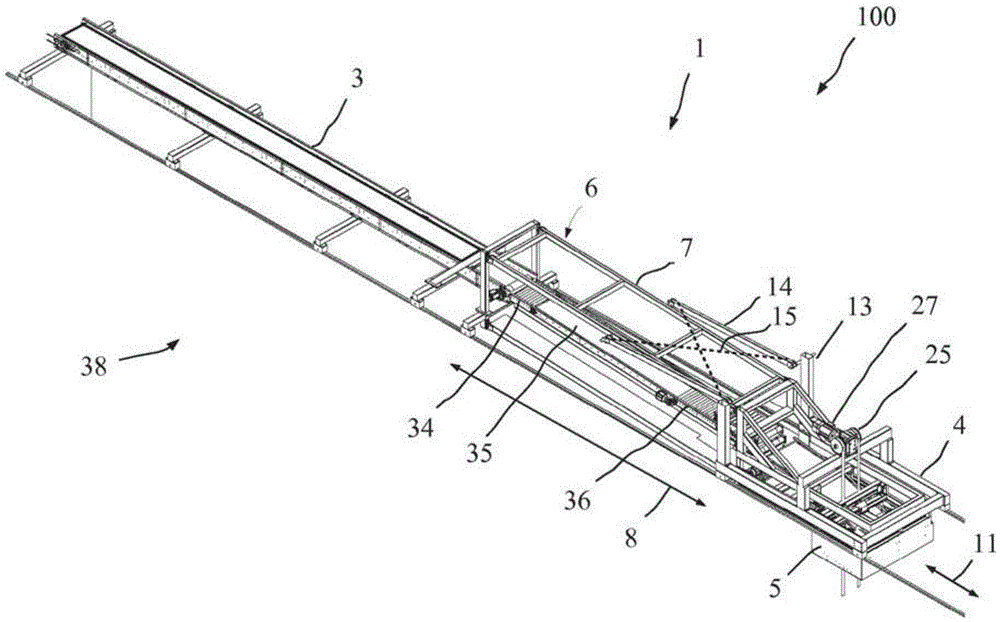

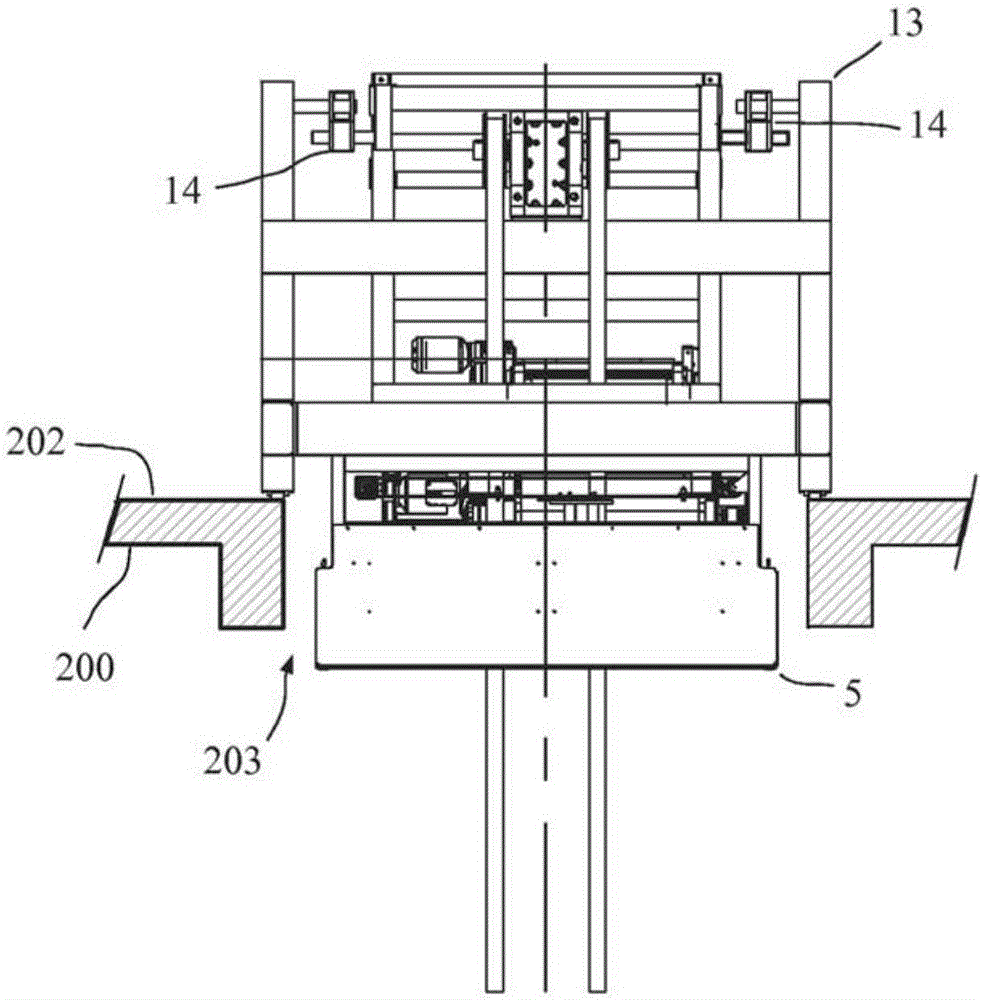

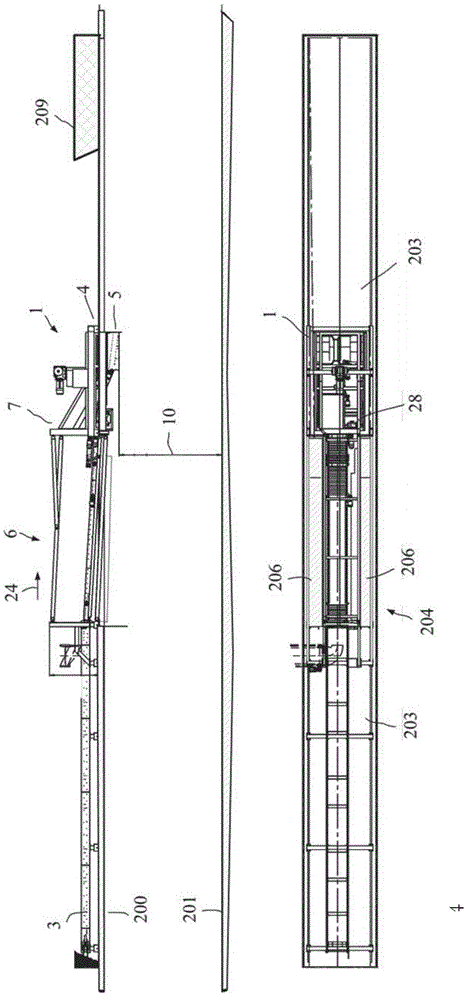

[0049] exist figure 1 A loader 100 according to the invention comprising a loading device 1 is schematically shown in perspective view of . The loader 100 is here placed on figure 1 In openings in the supporting device, not shown in detail, or on the building 200 . The loading device 1 is here arranged displaceably along a rail 211 in the longitudinal direction 11 and has a supply device 3 via which bags 2 or other individual goods, in particular filled with cement or other loose materials, are supplied. The supply device 3 takes over the bags 3 at a suitable location from a packaging machine not shown.

[0050] A conveyor belt is provided on the feeding device 3 , which feeds the bags to a conveying buffer device 6 , which connects the feeding device 3 to the loading head 5 . The loader head 5 is held on the mobile device 4 in a liftable and adjustable manner. When the loader head 5 was adjusted up and down, the loader head 5 remained in place in the longitudinal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com