Elastic batten used for bedstead

A slatted and elastic technology, applied in the field of upholstered furniture, can solve the problems of inability to relax muscles, complex disassembly and production, inconvenient use, etc., to increase air convection and service life, prevent deformation and breakage, and support reasonable and effective support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

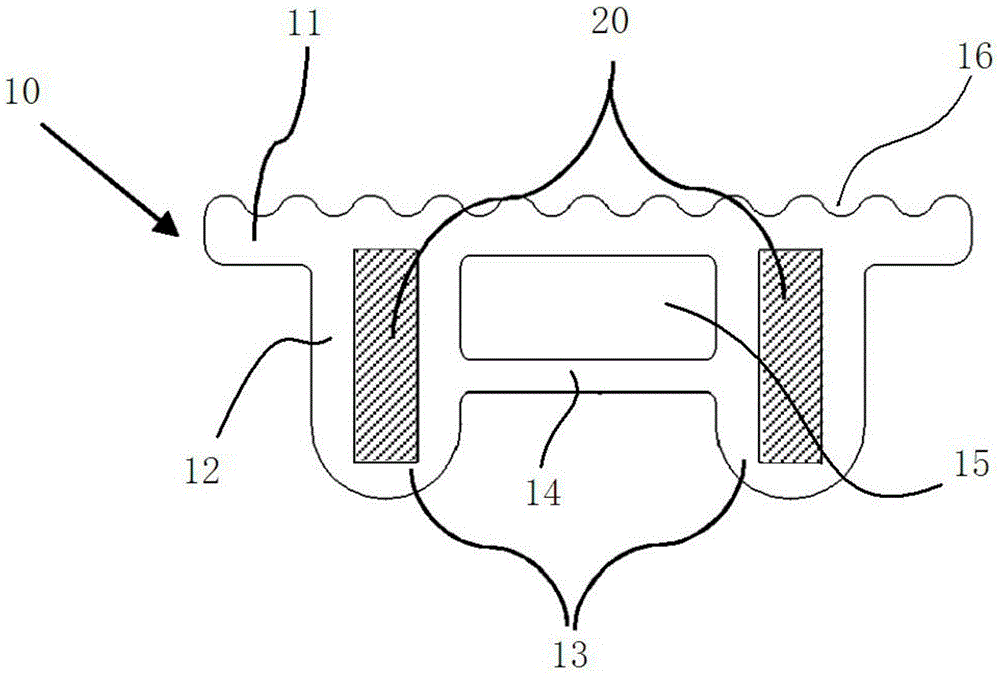

[0016] see figure 1 , an elastic slat for a bed frame in this embodiment, which includes a plastic slat body 10 and a glass fiber reinforcement 20 arranged in the plastic slat body 10, and the glass fiber reinforcement 20 is made of glass fiber material. The rectangular parallelepiped fiberglass slats, the plastic slat body 10 is made of thermal plastic material, which reduces the weight of the plate, and has supporting elasticity and an easy-to-clean surface.

[0017] In this embodiment, the plastic slat body 10 includes an upper slat 11, a reinforcing strip 12 and a connecting piece 14 connecting the lower ends of the two reinforcing strips. There are two reinforcing strips 12, and the two reinforcing strips 12 are respectively arranged At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com