Brush carrier capable of realizing section-by-section telescoping

A section-by-section, skeleton technology, which is applied to the field of segment-by-section retractable brush holders, can solve problems such as the problem of cleaning the brush tray combination storage, and achieve the effect of less wear and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, examples of the present invention will be described.

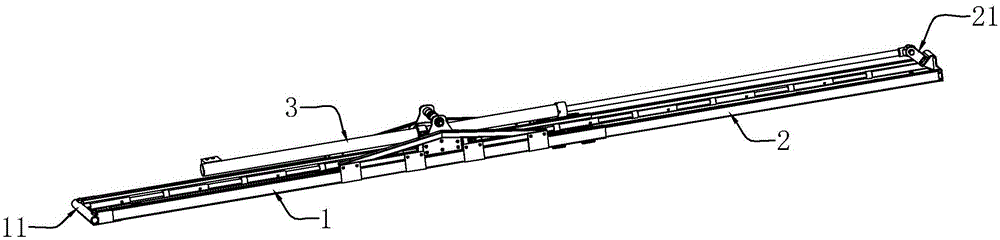

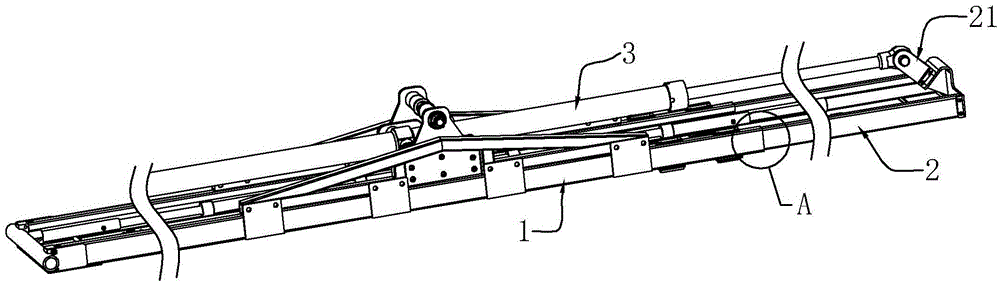

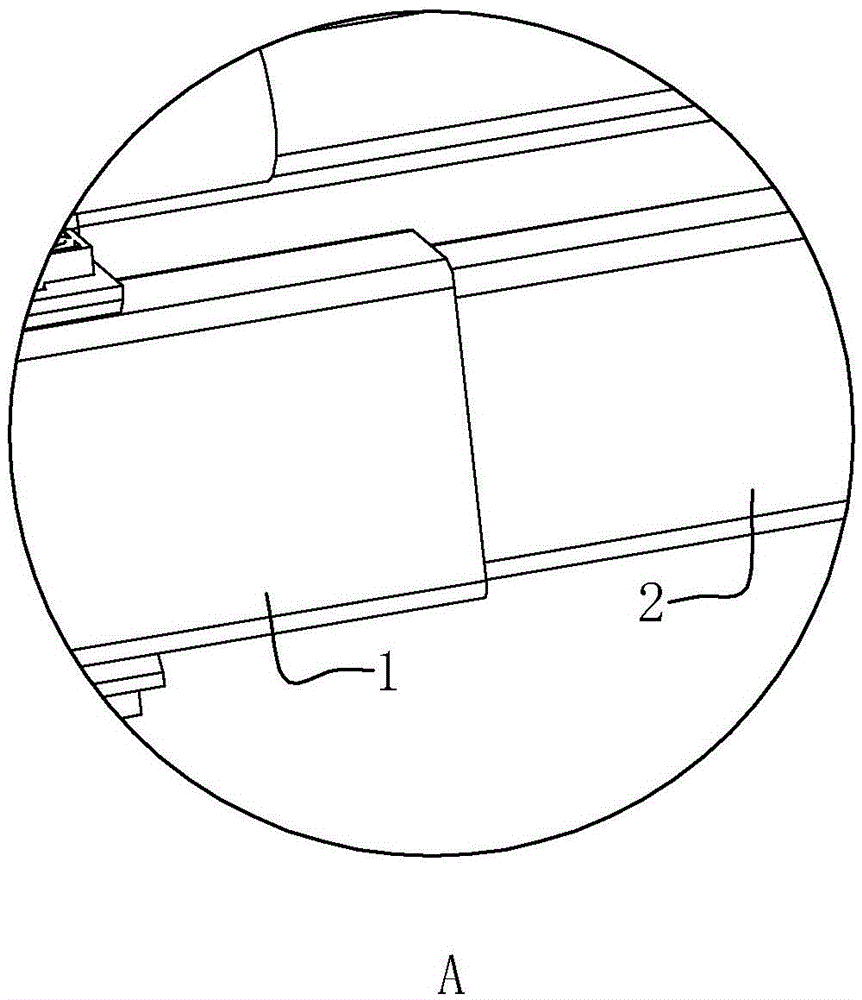

[0037] refer to Figure 1a and Figure 1b , the brush holder in this embodiment includes a lower frame 1 and an upper frame 2, the upper frame 2 is composed of small C-shaped steel on both sides and connectors 21, and the lower frame 1 is also composed of large C-shaped steel on both sides and connectors 11, Among them, the large C-shaped steel of the lower frame 1 envelops the small C-shaped steel of the upper frame, and the slide rail of the upper frame 2 in the lower frame 1 is formed between the two C-shaped steels. In addition, a hydraulic cylinder 3 is set on the brush frame. By fixing the hydraulic cylinder 3 on the lower frame 1 and connecting the movable end of the hydraulic cylinder 3 with the connecting piece 21, the upper frame 2 can be hydraulically driven to slide on the lower frame 1; figure 2 Shows the junction of the lower frame 1 and the upper frame 2.

[0038] refer to Figure 3a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com