TIG welding torque

A technology of welding torches and supports, applied in the field of TIG welding torches, can solve problems such as complex structures and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

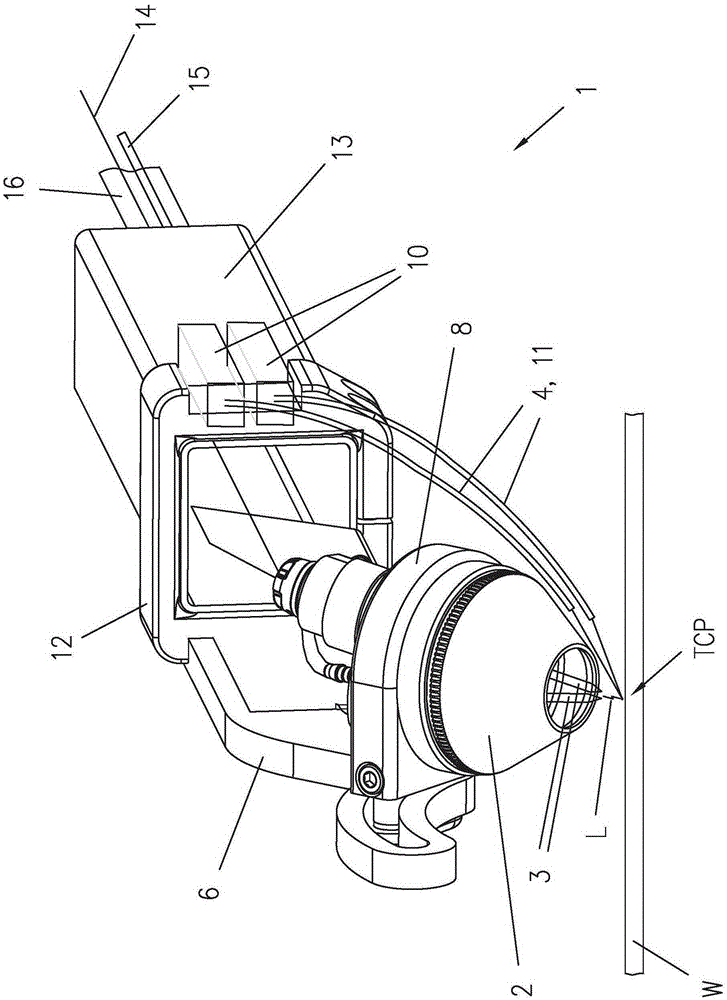

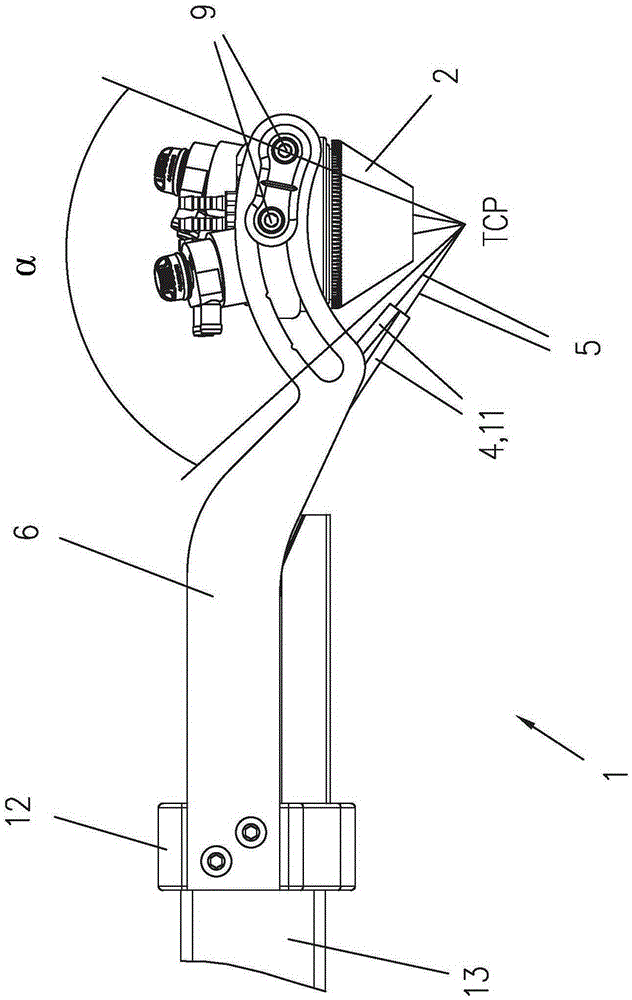

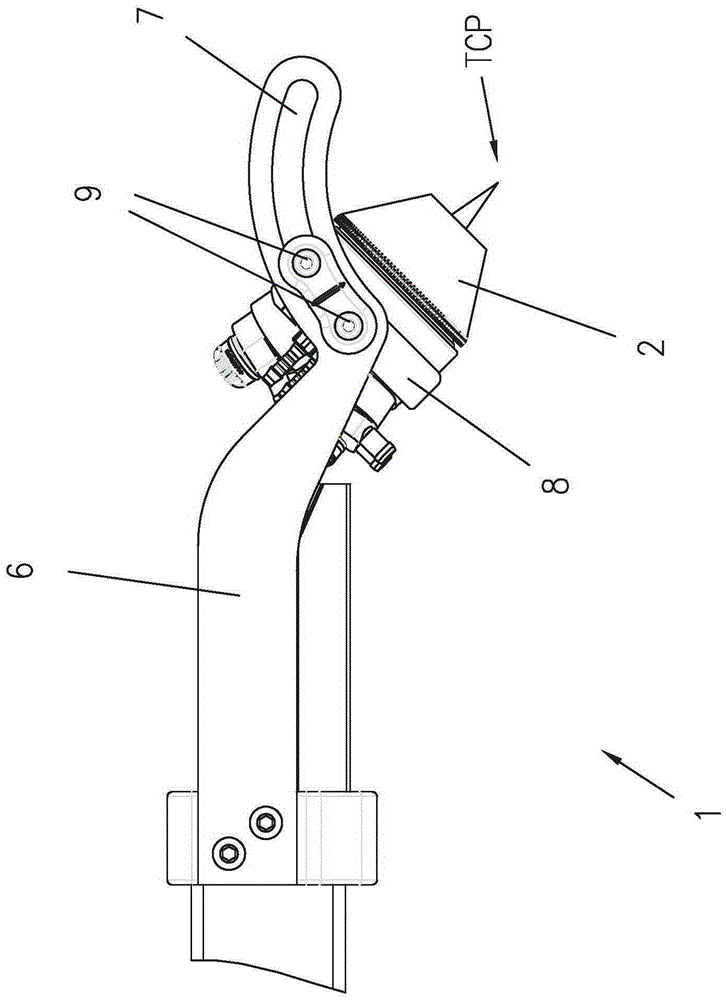

[0020] figure 1 A perspective view of one embodiment of a TIG welding torch 1 is shown. The TIG welding torch 1 comprises a torch head 2 in which at least one (preferably two) non-melting electrodes 3 are arranged, preferably non-melting tungsten electrodes. The non-fused electrode 3 is connected to a welding power source (not shown) through a suitable cable 14 so that the electrode 3 can be supplied with a suitable current. Commonly used shielding gases (argon, helium, etc.) are delivered to the welding point via the gas supply line 15 . Between the at least one non-melting electrode 3 and the workpiece W to be treated an electric arc L is ignited which melts at the tool center point (TCP) the at least one wire-like filler material 5 conveyed by the feed device 4 so that, for example, in the molten The molten filler material 5 is applied to the surface of the workpiece W during deposition (or deposition) welding. The longitudinal axis of each electrode 3 and the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com