Machining process for precise solenoid valve core

A processing technology and solenoid valve technology, applied in the field of mechanical manufacturing technology, can solve problems such as low product qualification rate, low production efficiency, and failure to achieve unified standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a process for processing the spool of a precision solenoid valve, which has good manufacturability, simple operation and low energy consumption.

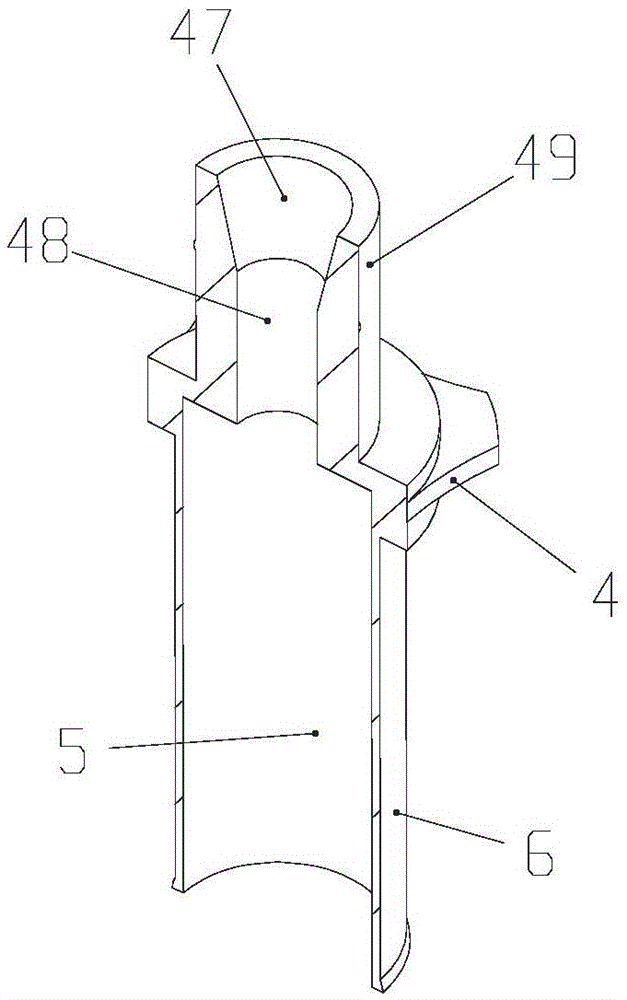

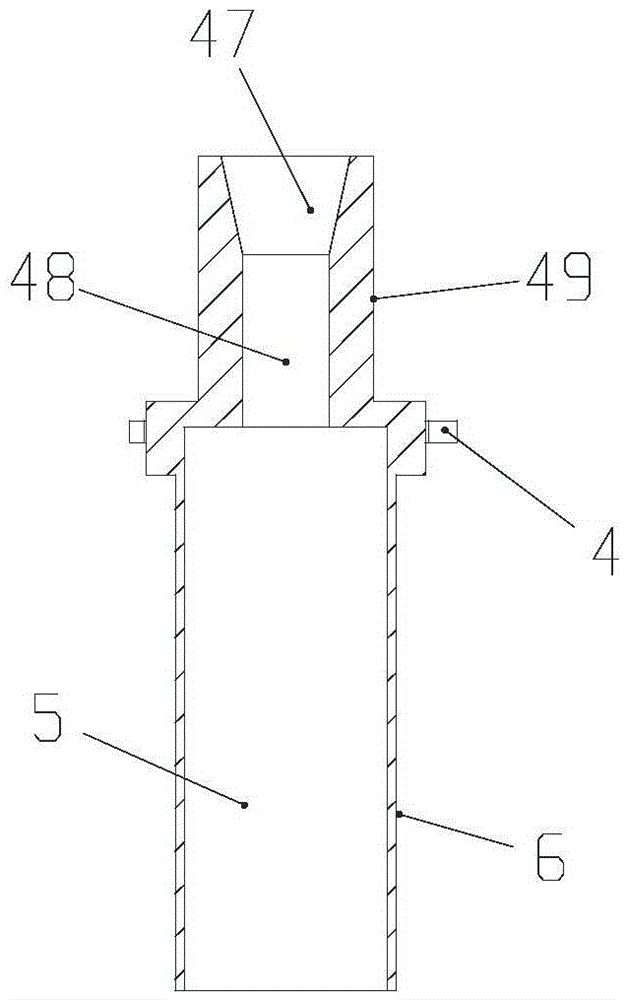

[0032] figure 1 , 2 It is a schematic diagram of the valve core structure of the processing technology of the precision solenoid valve core of the present invention. The valve body includes: an ear 4 located in the middle, an upper cylinder 49 located at the upper part of the ear 4, a lower cylinder 6 located at the lower part of the ear 4, a through hole 48 located inside the upper cylinder 49, Be connected to described through hole 48 and be positioned at the taper hole 47 of described upper cylinder 49 inside, be positioned at the large hole 5 of described lower cylinder 6 inside; The wall thickness of described lower cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com