Automatic assembling robot for battery cover plate drain hole plug

A battery cover, automatic assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, unguaranteed tightening quality of liquid hole plugs, poor sealing, etc., to improve efficiency and convenience. The effect of production and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

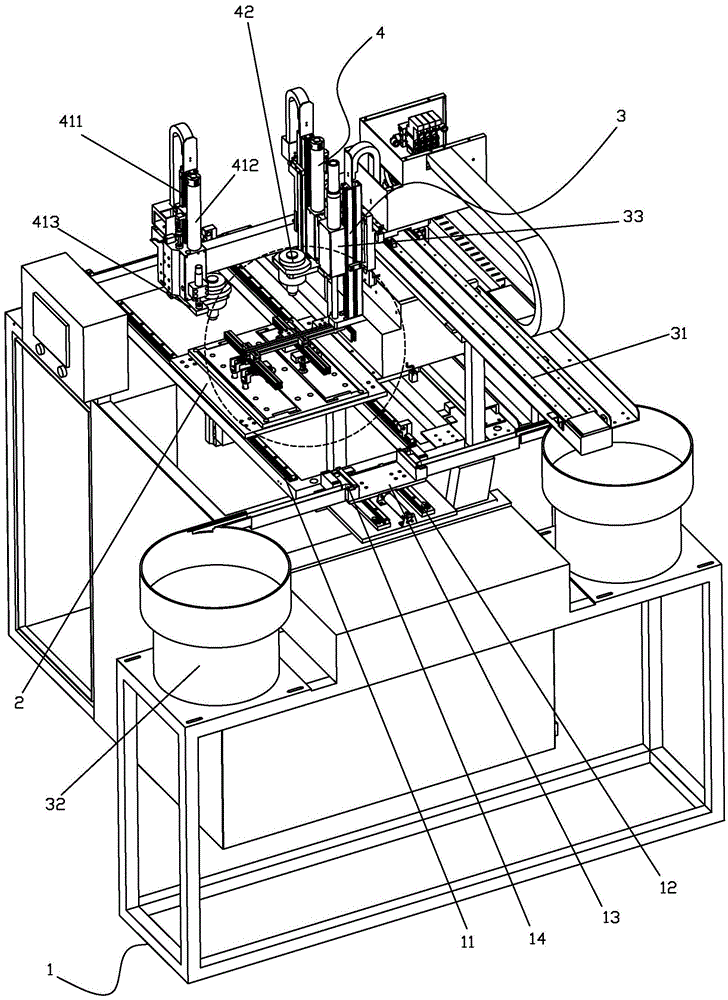

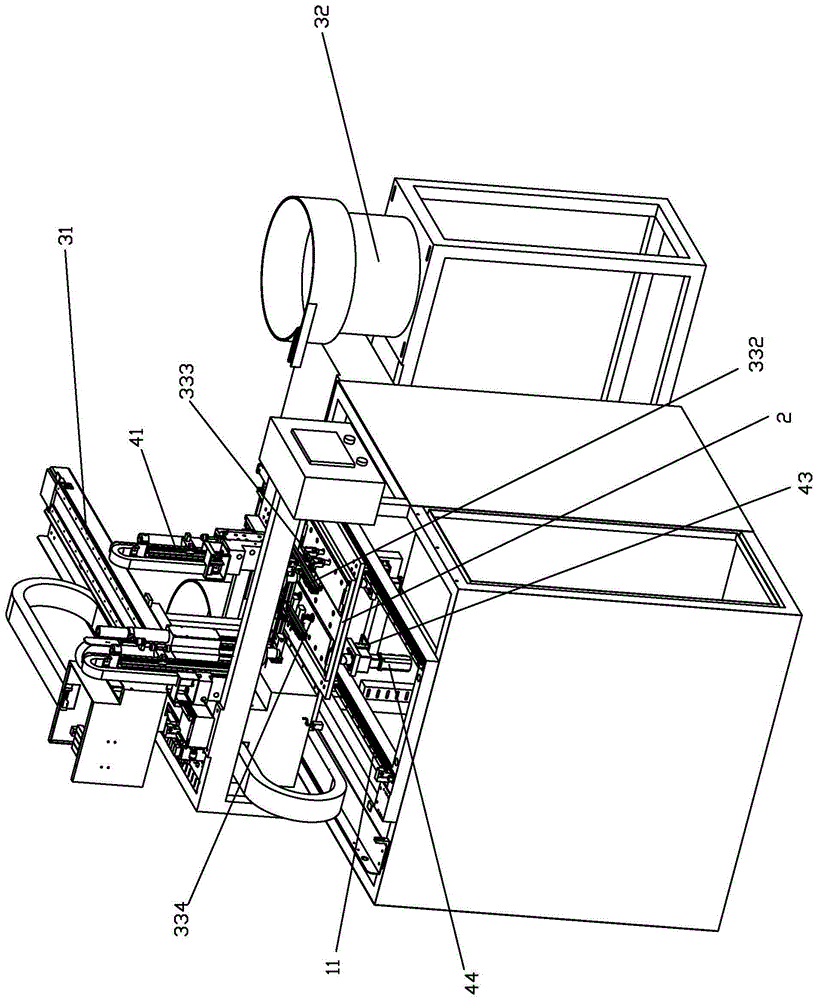

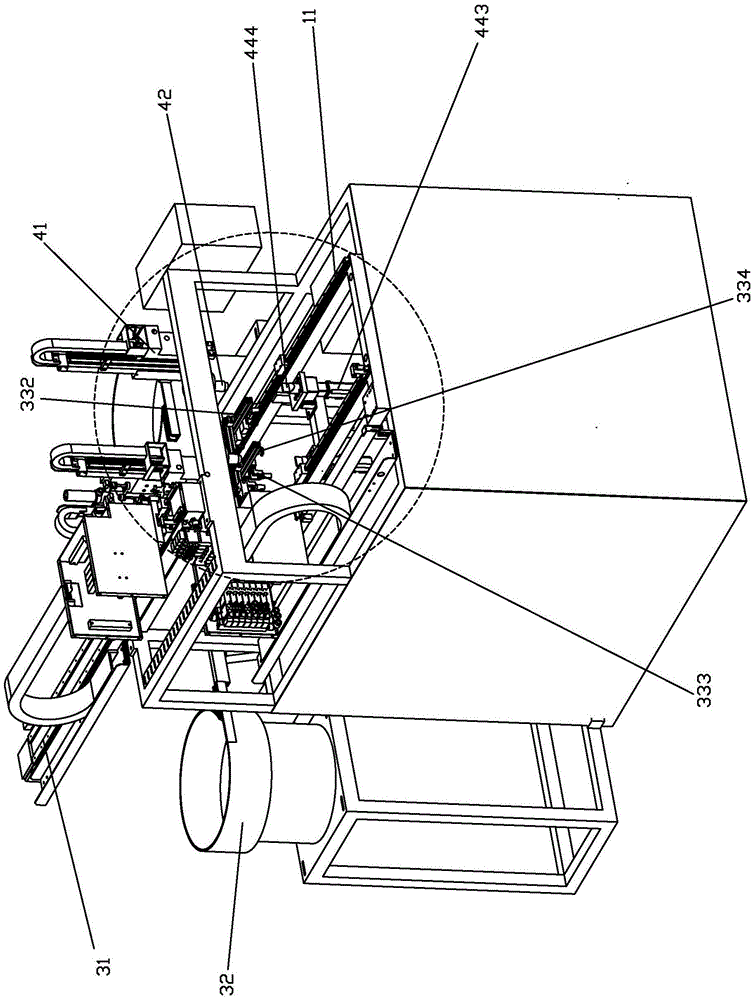

[0022] An automatic battery cover liquid hole plug assembly robot, including a frame 1, the frame 1 is provided with a bottom slide rail 11, and the bottom slide rail 11 is provided with a cover plate clamp for driving the battery cover plate to move laterally Holding mechanism 2, the frame 1 is located above the cover plate clamping mechanism 2 and is provided with an automatic pick-and-place mechanism 3 for automatically taking out the liquid hole plug and placing it in the liquid injection hole of the battery cover plate. The frame 1 is also provided with an automatic screw-in mechanism 4 for pressing the liquid hole plug and screwing it into the liquid injection hole. The battery cover is fixed on the cover clamping mechanism, the liquid hole plug is picked up by the automatic pick-and-place mechanism and placed in the liquid injection hole of the cover plate, and then the liquid hole plug is screwed into the liquid injection hole by the automatic screw-in mechanism , to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com