Light guide plate cooling equipment provided with storing device

A storage device and light guide plate technology, applied in the field of light guide plates, can solve the problems of loss of air volume, increase in cost, decrease in manufacturing capacity, etc., and achieve the effects of reducing manufacturing output, reducing manufacturing capacity and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

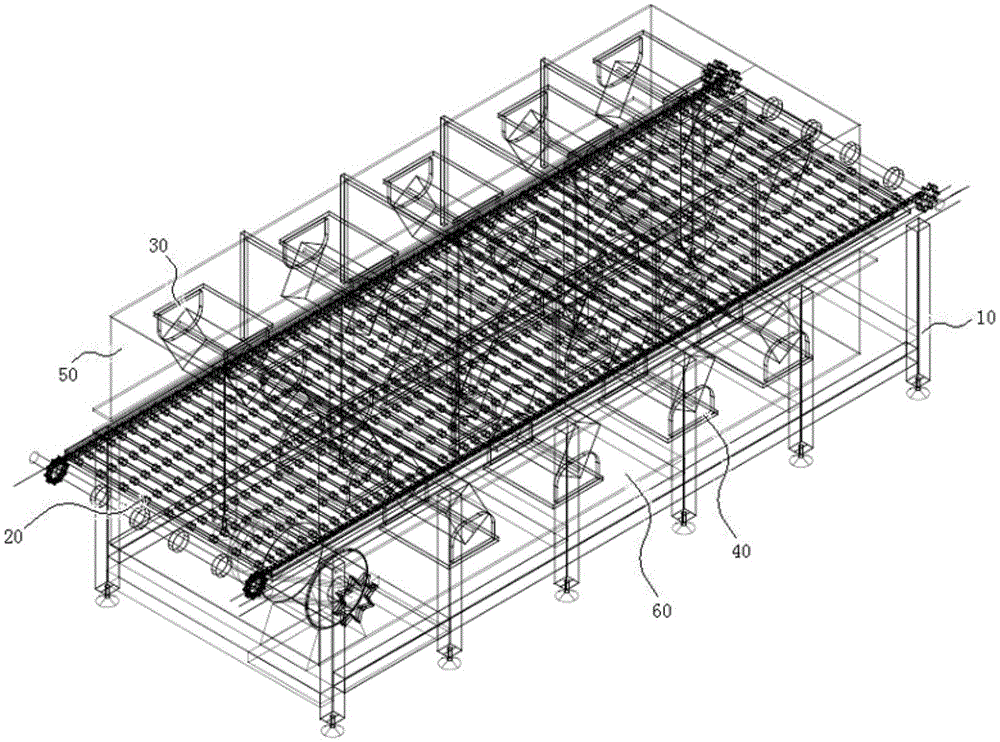

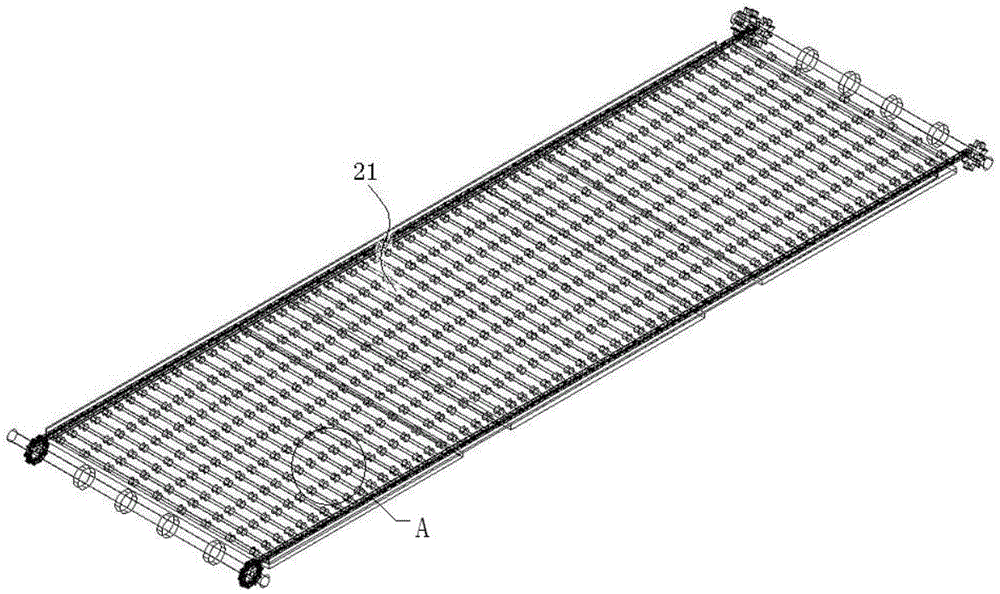

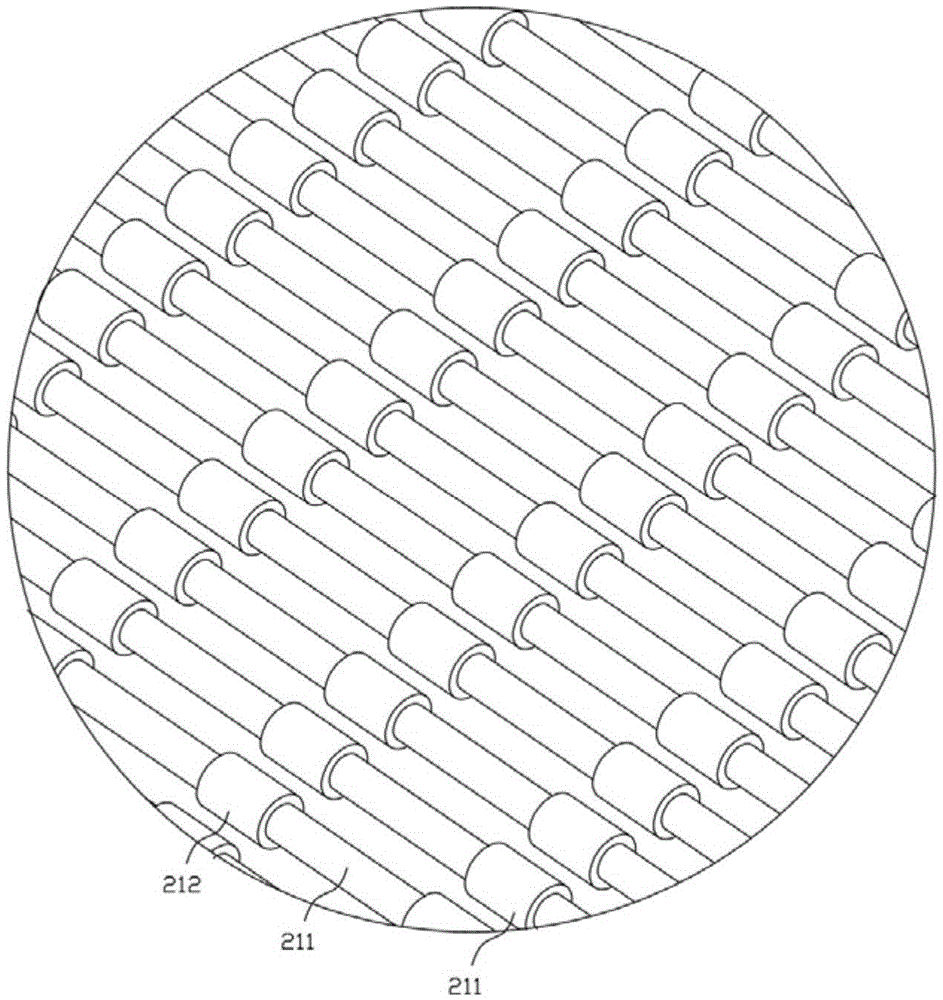

[0042] combine figure 1 , Figure 4 , Figure 5 , a light guide plate cooling device with a storage device, including a main frame 10, a transmission device 20 installed on the main frame, an upper wind drum 30 and a lower wind drum 40 installed on the main frame, a light guide plate cooling jig 70 and a cooling Fixture storage device 80.

[0043] like figure 1 , the upper wind drum 30 is located above the transmission device, and the lower wind drum 40 is located below the transmission device. The upper wind drum 30 and the lower wind drum 40 are fixed on the main frame 10 through profiles; the upper wind drum and the lower wind drum are arranged in two rows along the conveying direction of the conveying device 20; the power supply mode of the upper wind drum and the lower wind drum is parallel connection; The direction of the wind speed of the upper wind drum and the lower wind drum is to suck wind from the front and to blow wind from the back.

[0044] combine figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com