Water separator for single-crystal furnace cooling system

A cooling system and water separator technology, applied in crystal growth, chemical instruments and methods, post-processing devices, etc., can solve problems such as water flow diffusion that cannot be separated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

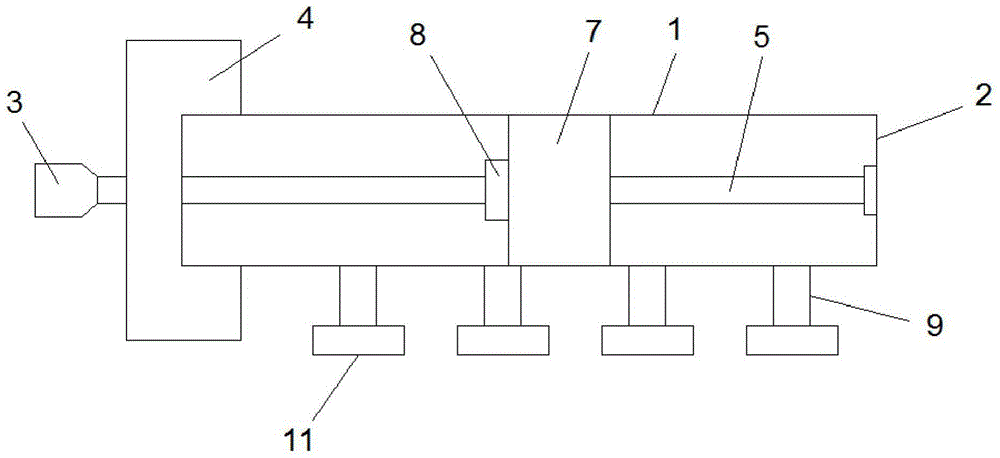

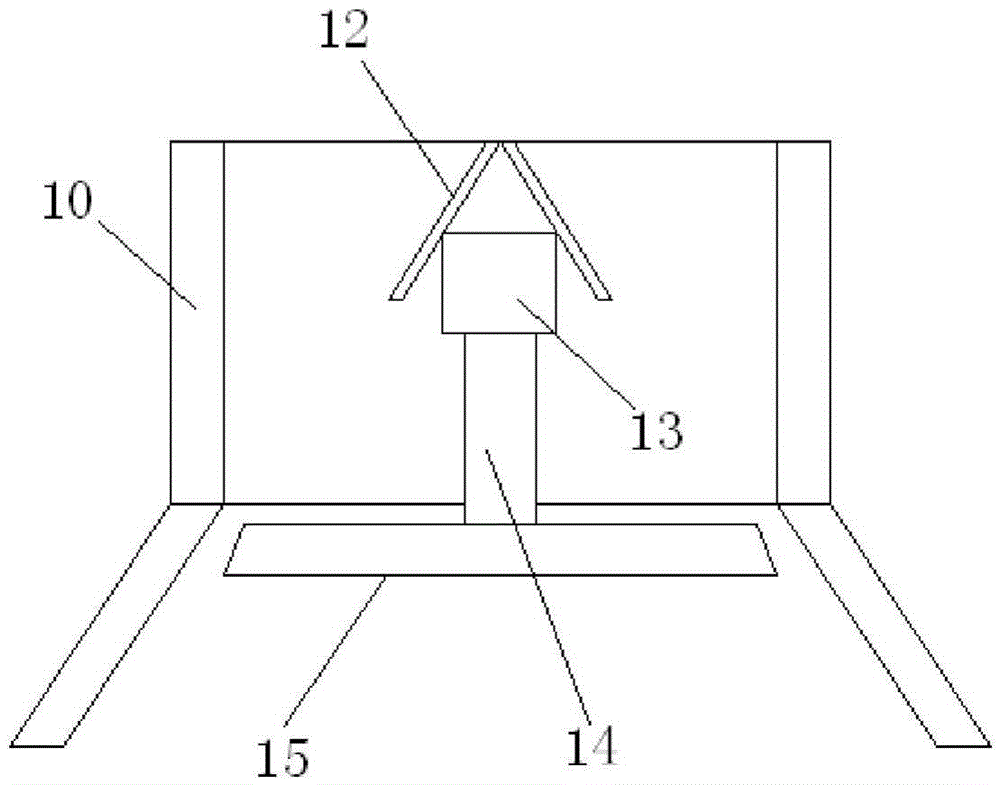

[0015] Such as figure 1 A water distributor for the cooling system of a single crystal furnace is shown, including a water distributor main body 1, a sealing cover 4, a piston valve core 7 and a dispersion device 11, and the water distributor main body 1 is a hollow circle One end of the main body of the water separator 1 is provided with a water inlet 2, and the bottom of the main body of the water separator 1 is provided with four water outlets 9 in sequence, and the sealing cover 4 is fixedly installed on the main body of the water separator. 1, the piston spool 7 is movably connected in the main body 1 of the water distributor, the piston spool 7 is connected with the translation mechanism, and the four outlets at the bottom of the main body 1 of the water distributor A dispersing device is respectively installed at the lower end of the nozzle. When working, the water flow will flow into the water distributor body 1 along the water inlet 2, and then start the translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com