Non-dismantling template integrating grade-A heat preservation and cast-in-situ concrete

A formwork-free, cast-in-place concrete technology, applied in thermal insulation, building components, walls, etc., can solve the problems of easy loss of wood formwork, less turnover, difficult to clean, etc., to solve common quality problems, easy construction, and reduce building energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

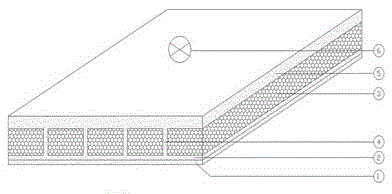

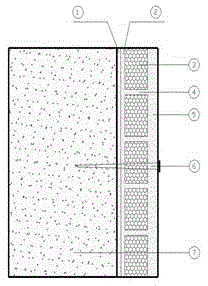

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] In the figure: 1-supporting plate; 2-adhesive mortar; 3-A grade insulation board; 4-light aggregate polymer inorganic insulation mortar; 5-cement-based polymer modified mortar; 6-special anchor; 7- Concrete exterior walls.

[0014] A dismantling-free formwork integrating Class A thermal insulation and cast-in-place concrete, including a supporting plate 1, one side of which is in contact with the cast-in-situ concrete outer wall 7, and the other side is covered with adhesive mortar 2 and bonded with Class A thermal insulation at intervals Board 3, fill the interval area of the A-level insulation board with light aggregate polymer inorganic insulation mortar 4 to form an integral insulation board connected with each other, and then compound the cement-based polymer modified mortar 5 on the outside of the A-level insulation board 3 , and press into the alkali-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com