Axial magnetic suspension bearing

A magnetic levitation bearing, axial technology, applied in the direction of magnetic bearings, shafts and bearings, bearings, etc., can solve the problems of difficult control of product qualification rate, inability to directly adjust, poor quality flexibility, etc., to eliminate multiple heat-loaded bearing rotors, It is easy to adjust the protection gap and avoid the effect of reducing the amount of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

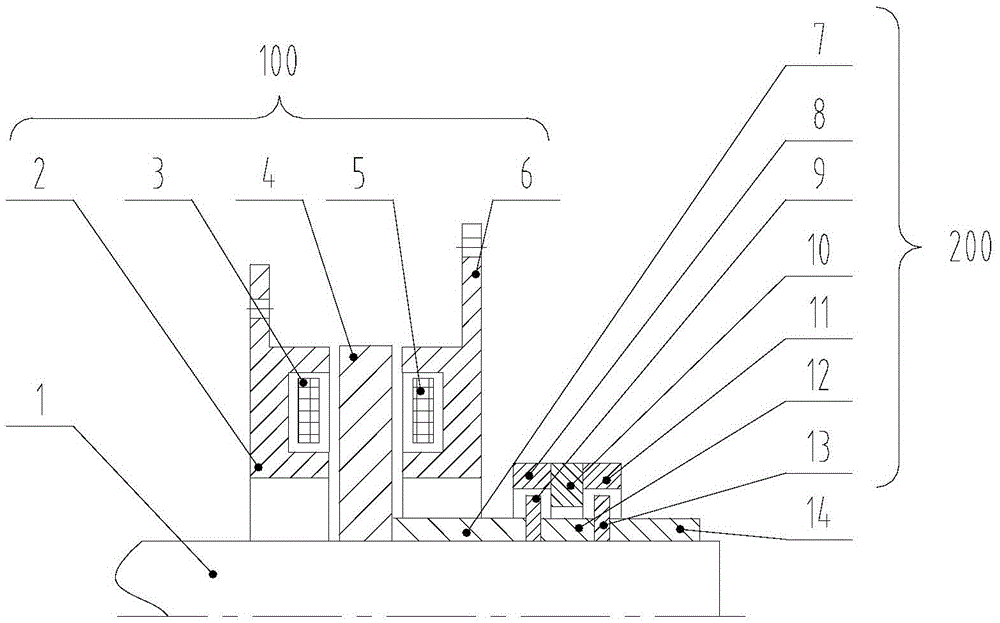

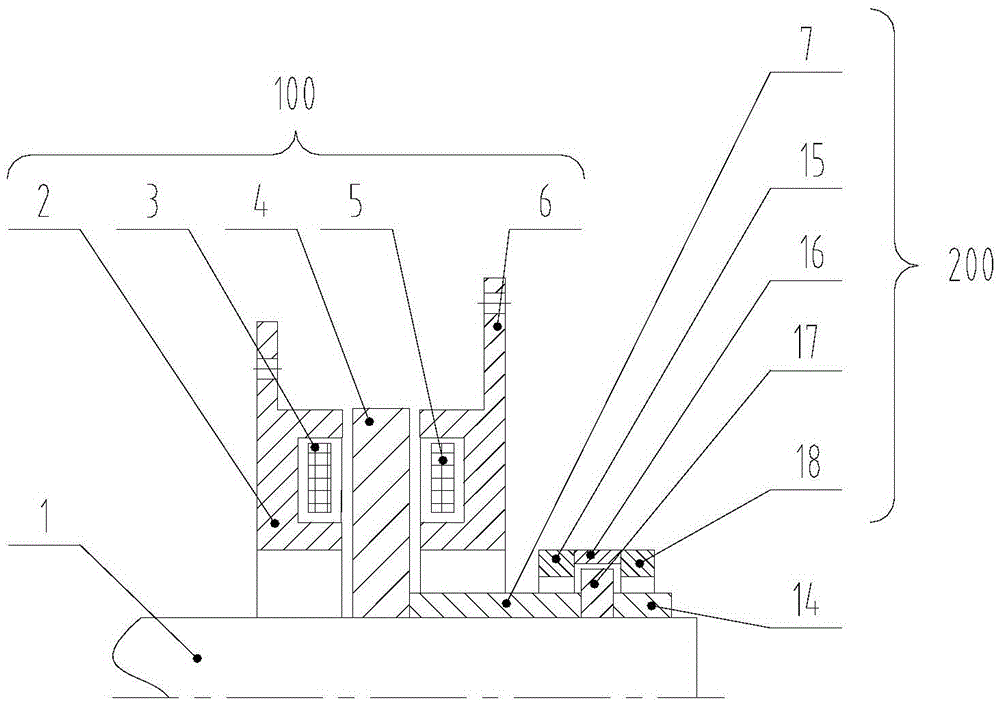

[0024] see figure 1 and figure 2 , the present invention provides an axial magnetic suspension bearing in view of the aforementioned status of the prior art, which includes a bearing body 100 and a protection device 200, and the bearing body 100 includes a stator and a rotor. Wherein, the protection device 200 includes a first assembly fixedly installed relative to the stator and a second assembly fixedly installed relative to the rotor, one of the first assembly and the second assembly includes a first Stops (for example, figure 1 The part indicated by the number 10 in, or figure 2 17), the other of the first assembly and the second assembly includes a second stopper (for example, figure 1 The parts indicated by the number 9 in, or figure 2 Parts indicated by the number 15) and the third stopper (for example, figure 1 The part indicated by the number 13 in, or figure 2 18), a part of the first stop part is located between the second stop part and the third stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com