Fluid switch valve

A fluid switch and valve seat technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of large fluid kinetic energy loss, large switch driving torque, and flow velocity disorder, and achieve small flow area difference and on-off control The effect of small force and small loss of kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

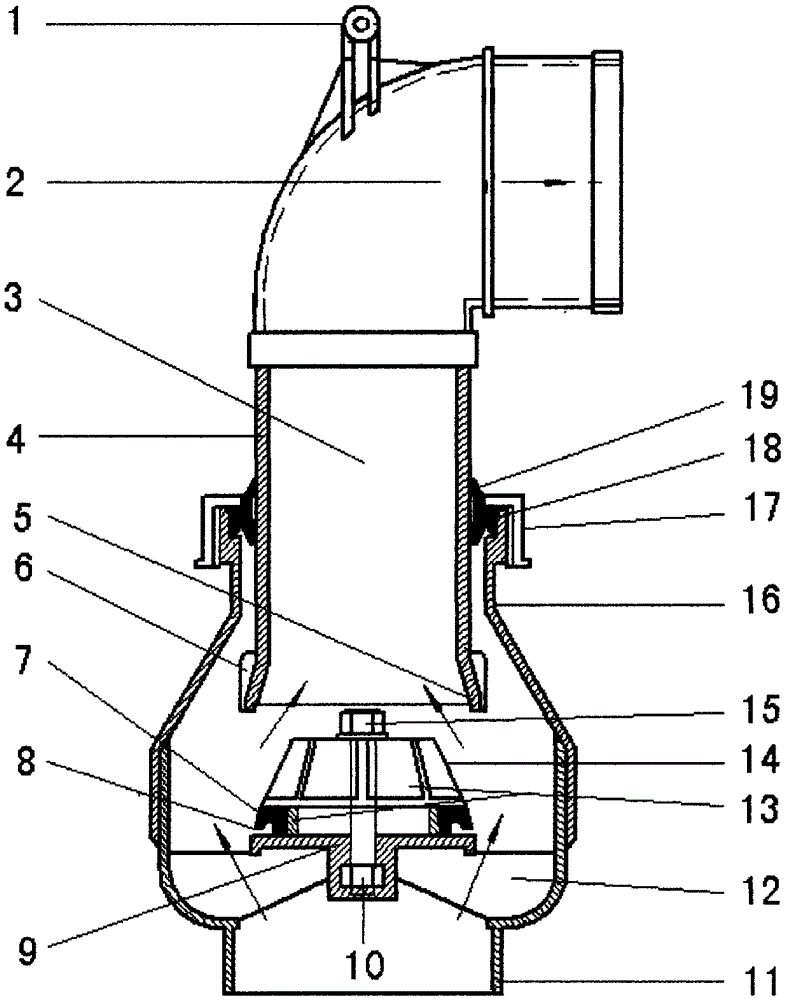

[0009] exist figure 1 , the handle (1), elbow (2) and valve pipe (3) are fixedly connected together. The base (11) and the valve outer pipe (16) are fixedly connected together. The sealing seat (9) is fixedly connected with the base (11) through the bracket (12), and the conical fixed cover (13) and sealing ring (7) are fixed on the valve seat ( 9) on. The screw cover (17) fixes the two-way sealing ring (19) in the sealing groove (18) at the top of the outer tube (16) of the valve to form a leak-proof seal. The conical fixed cover (13) is in the shape of a truncated cone, and its function is to fix the sealing ring (7). When the valve pipe (3) moves downward, the sealing port (5) is guided by the conical inclined surface (14), so that the sealing The ring (7) enters the sealing port (5) smoothly.

[0010] Closing process: press the handle (1) downward, the valve pipe (3) moves downward, guided by the tapered surface (14) of the tapered fixed cover (13), the sealing ring (7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com