Compact fan heater

A heater and a compact technology, applied in the field of compact fan heaters and their manufacturing processes, can solve the problems of the electrical components of the heater stop working, it is difficult to dissipate heat, waste time and experience, etc., so as to increase the ventilation effect. , the structure is simple, the effect of improving the protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

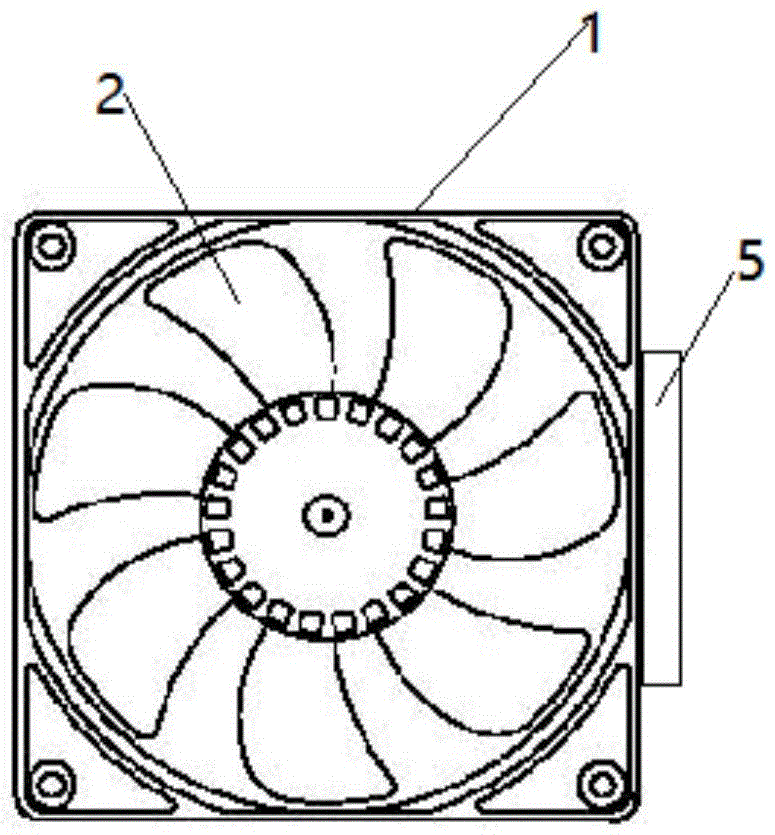

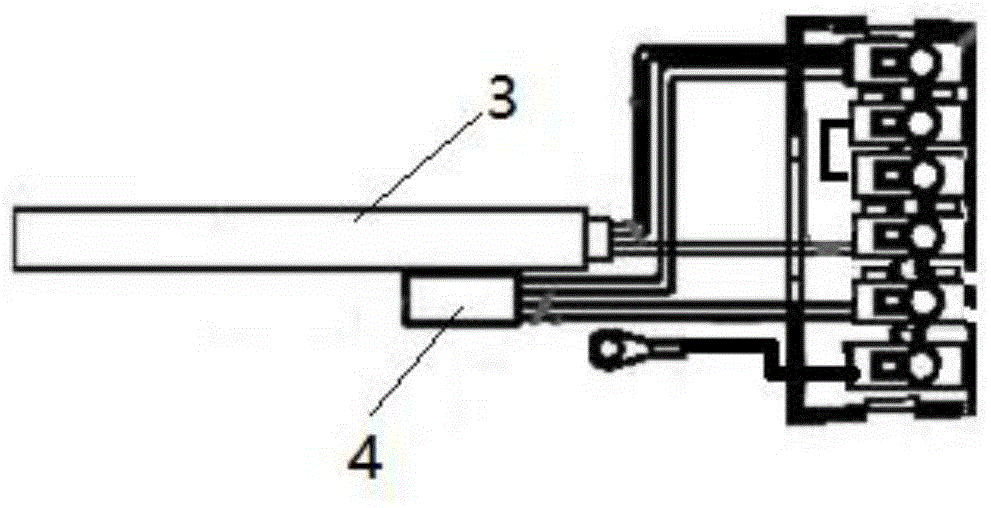

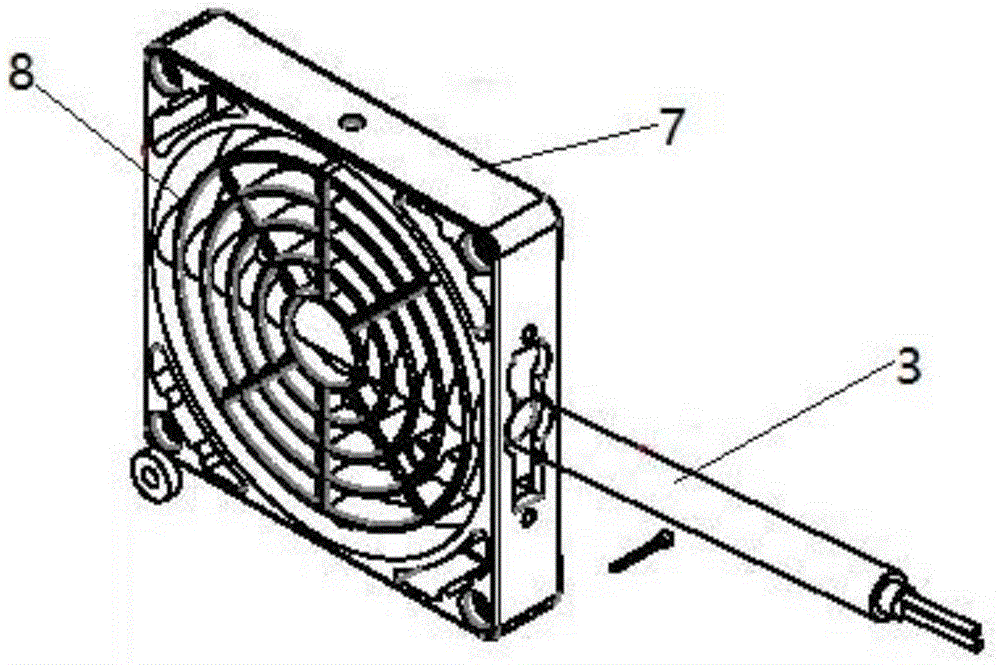

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 A compact fan heater shown includes: a housing 1, a fan 2, a heating tube 3, a thermostat 4, a power box 5 and a control device,

[0037] The housing 1 is composed of a front cover and a rear shell, the front cover and the rear shell are connected with the profile 7 by screws, the front cover is provided with a hand guard 8, the fan 2, the heating Both the tube 3 and the temperature controller 4 are located inside the housing 1, the power supply box 5 is located on one side of the housing 1, and the heating tube 3 and the temperature controller 4 are connected through the heating tube leads and the temperature controller respectively. The lead wire of the device is connected with the terminal 6 in the power supply box 5, and the control device is located in the power supply box 5, and the fan 2, the heating pipe 3 and the temperature controller 4 are all connected with the control device.

[0038] The fan 2 descr...

Embodiment 2

[0043] The structure of the fan heater in the working method of a compact fan heater described in this embodiment is the same as that in Embodiment 1.

[0044] A working method of a compact fan heater, the specific working method is as follows:

[0045] (1): First connect the heater to an external circuit;

[0046] (2): When the heater is connected to the external circuit, start to turn on the power to let it start to work;

[0047] (3): After the power is turned on, the heating tube 3 starts to work;

[0048] (4): The heating tube 3 will be continuously heated, and during the continuous heating process, the fan 2 is also continuously running;

[0049] (5): After the fan 2 works, it continuously dissipates the heat generated by the heater itself to ensure that it can work normally for a long time;

[0050] (6): During the above working process, once the temperature inside the heater reaches the maximum value preset by the thermostat (4), the thermostat 4 will automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com