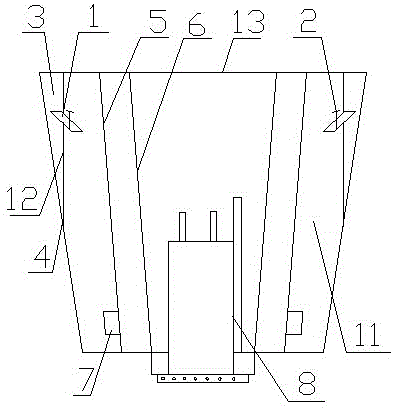

Hot air distribution device of spray-drying tower

A technology of spray drying tower and hot air distribution, applied in drying gas arrangement, drying, dryer and other directions, can solve the problems of sticking to the wall, material and hot air cannot be evenly mixed, uneven distribution of hot air, etc., to prevent the phenomenon of sticking to the wall. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is described in further detail:

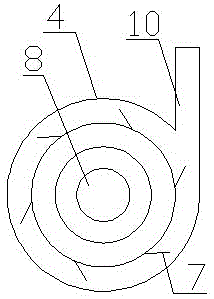

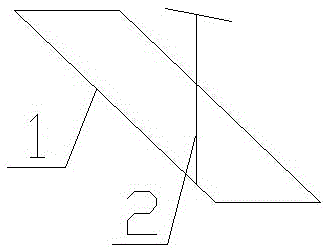

[0025] Such as figure 1 As shown, the present invention includes three concentrically set inverted truncated cone shells, and the three inverted truncated cone shaped shells are connected by a top cover 13; the upper part of the outer inverted truncated cone shaped shell 4 is divided into a wind inlet volute by a cylinder 12 Shell 3, and evenly install several air inlet pipes 1 that can adjust the air intake volume on the cylinder 12, so that the air inlet pipe 1 is connected to the air inlet volute 3 and the outer inverted frustum-shaped casing 4 and the middle inverted frustum-shaped casing 5 An air duct 11 is formed; the deflector 7 is evenly installed on the lower part of the outer wall of the middle inverted frustum-shaped housing 4; 5 inside; the external air duct 10 is connected with the air inlet volute 3, in order to allow the external hot air to maintain a relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com