Four degrees of freedom self-positioning high-and-low temperature resistant tension, pressure and durability testing machine

A technology of high and low temperature resistance and durability test, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc. It can solve the problems of complex operation of industrial robots, slow movement of cylinders, waste of power resources, etc., and achieve the direction of testing. Flexible, avoid shaking, and bear the effect of heavy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

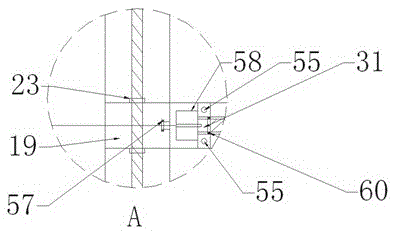

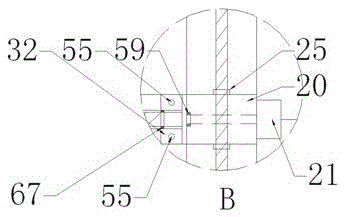

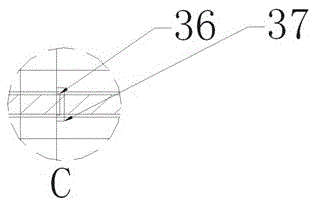

[0020] see Figure 1-10 , a four-degree-of-freedom self-positioning high and low temperature resistant tensile pressure and durability testing machine, comprising a testing machine base plate 1, a front support plate 40 and a rear support plate 41 are arranged below the testing machine base plate 1, and rollers 28 and anchor bolts 24 are respectively Fix the front support plate 40 and the rear support plate 41, the anchor bolt 24 is a larger cylinder at the bottom, and the top is a bolt, the bolt is connected with the cylinder, and the bolt and the cylinder can be rotated, and the anchor bolt 24 is connected to the cylinder. Screw the bolt 24 to separate from the ground, push the whole testing machine, the roller 28 rotates, and then the whole testing machine will move, and can be easily pushed into the high and low temperature test chamber. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com