Piston type fixed-depth soil core sampling device and use method thereof

A sampling device and piston-type technology, applied in the field of soil core sampling devices, can solve the problems of significant sampling error and difficulty in excavation, and achieve the effects of quality assurance, accurate sampling depth and high soil extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

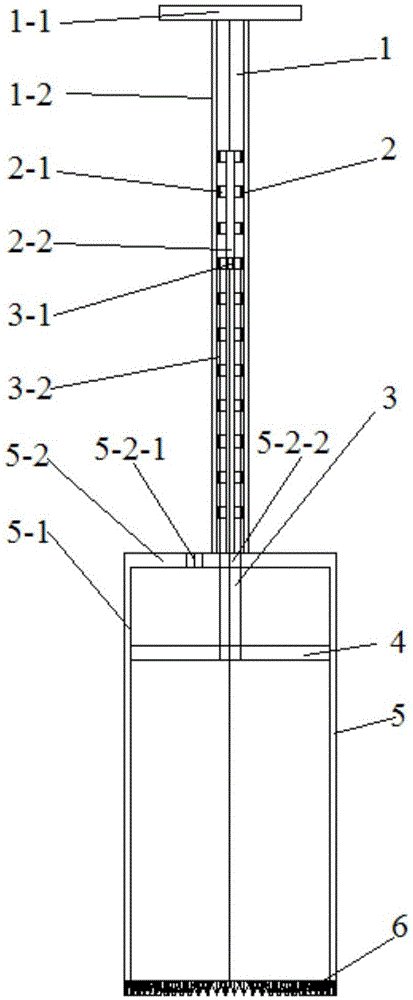

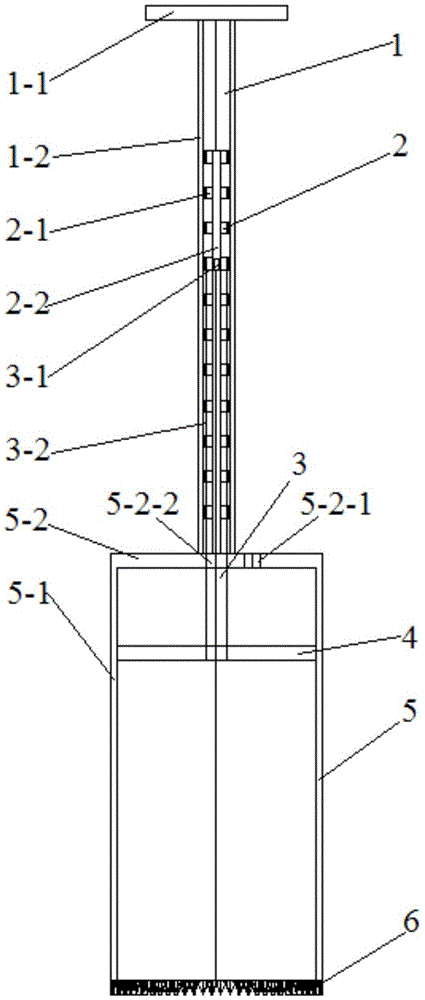

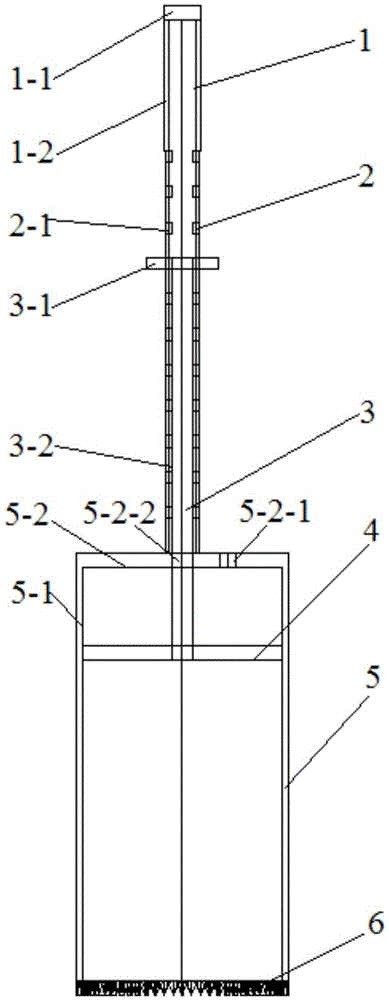

[0019] Specific implementation mode one: combine figure 1 with 2 , the present embodiment is a piston-type fixed-depth soil core sampling device, which includes a drill handle 1, a push rod slot 2, a piston push rod 3, a piston 4, a drill bit 5 and a drill bit serration 6, and the drill bit 5 is a cylinder shaped stainless steel tube, the cylindrical stainless steel tube is composed of a top cover 5-2 and a tube wall 5-1, the top cover 5-2 and the tube wall 5-1 are welded together, and the top cover 5- 2 is provided with an air outlet 5-2-1 and a connecting rod hole 5-2-2; the piston push rod 3 is composed of a handle 3-1 and a connecting rod 3-2, and the connecting rod 3-2 It is welded together with the handle 3-1, and the connecting rod 3-2 is connected with the piston 4 through the connecting rod hole 5-2-2 on the top cover 5-2; the drill handle 1 is composed of the drill rod 1 -2 and the handle 1-1, the drill rod 1-2 and the handle 1-1 are welded together, the drill rod ...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 with 2 The difference between this embodiment and the first embodiment is: the drill bit 5 is a cylindrical stainless steel cylinder, and the diameter of the cavity of the cylindrical stainless steel cylinder is 50mm-200mm, and the length of the cylindrical stainless steel cylinder is 100mm-1000mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 with 2 The difference between this embodiment and the specific embodiment 1 or 2 is: the push rod slot 2 is engraved on the drill rod 1-2 of the drill shank 1 . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com