Frame-type power supply track and track equipment based on the power supply track

A power supply rail and frame type technology, applied in transformer/inductor parts, circuits, electrical components, etc., can solve problems such as poor system operation performance, and achieve the effects of small magnetic field leakage, low manufacturing cost, and low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

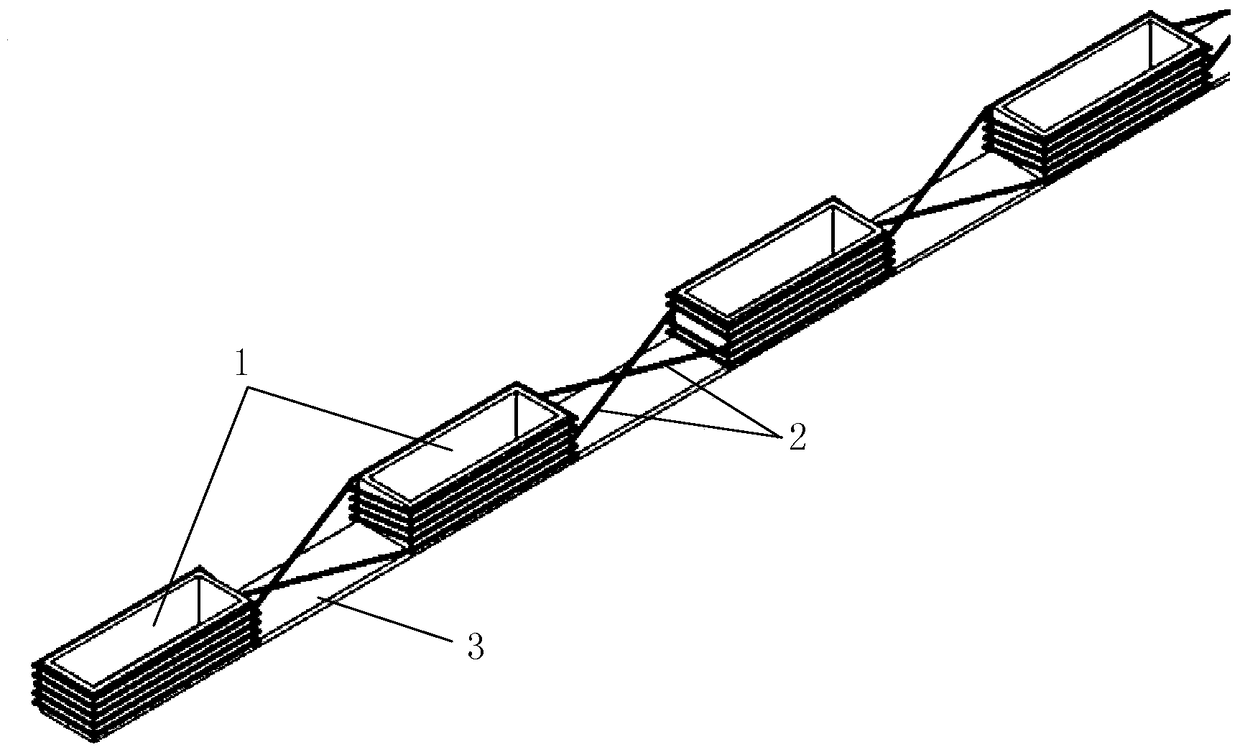

[0023] Specific implementation mode one, reference Figure 1 to Figure 4 To describe this embodiment in detail, the frame-shaped power supply rail for wireless power supply for mobile transportation equipment described in this embodiment includes n magnetic poles 1, power supply cables 2 and magnetic cores 3, 2≤n, and n is an integer;

[0024] The n magnetic poles 1 are all hollow rectangular frame structures; the magnetic core 3 is a flat magnetic core; the bottom width of the magnetic pole 1 is equal to the width of the magnetic core 3; the bottom of the n magnetic poles 1 are all fixed on the magnetic core 3;

[0025] The power supply cable 2 is wound along the outer surface of the magnetic pole 1, from bottom to top along the outer surface of the first magnetic pole 1 to the middle position of the first magnetic pole 1, and then continues to wind along the outer surface of the second magnetic pole 1 from bottom to top To the middle position of the second magnetic pole 1, and so...

specific Embodiment approach 2

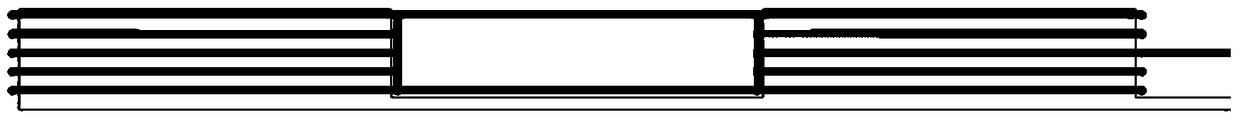

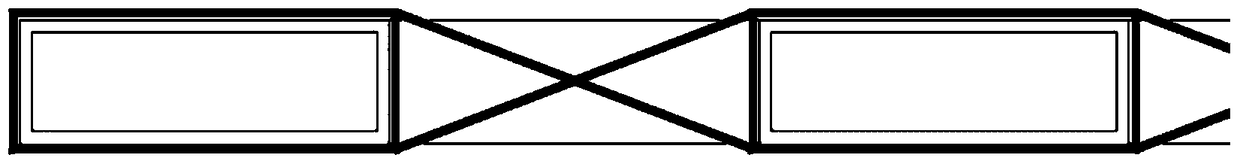

[0027] Specific implementation mode two, reference Figure 5 To describe this embodiment in detail, the frame-shaped power supply rail for wireless power supply for mobile transportation equipment described in this embodiment includes n magnetic poles 1, power supply cables 2 and magnetic cores 3, 2≤n, and n is an integer;

[0028] The n magnetic poles 1 are all hollow rectangular frame structures; the magnetic core 3 is a flat magnetic core; the bottom width of the magnetic pole 1 is equal to the width of the magnetic core 3; the bottom of the n magnetic poles 1 are all fixed on the magnetic core 3;

[0029] The power supply cable 2 is wound along the outer surface of the magnetic pole 1, and first wound along the same height as the first magnetic pole, the second magnetic pole,..., the n-1th magnetic pole, and the nth magnetic pole outer surface. The winding method is cross-winding along one side of the first magnetic pole, the other side of the second magnetic pole,..., one side ...

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment is a further description of the frame-shaped power supply track applied to the wireless power supply of mobile transportation equipment described in Embodiment 1 or 2. In this embodiment, the magnetic pole 1 is a ferrite pole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com