Hollow T-shaped power supply rail applicable for wireless power supply to electromobile and rail device containing power supply rail

A wireless power supply and power supply rail technology, applied in electric vehicles, transformer/inductor coils/windings/connections, vehicle energy storage, etc., can solve the problems of high battery pollution, high operation and maintenance costs, and short driving range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

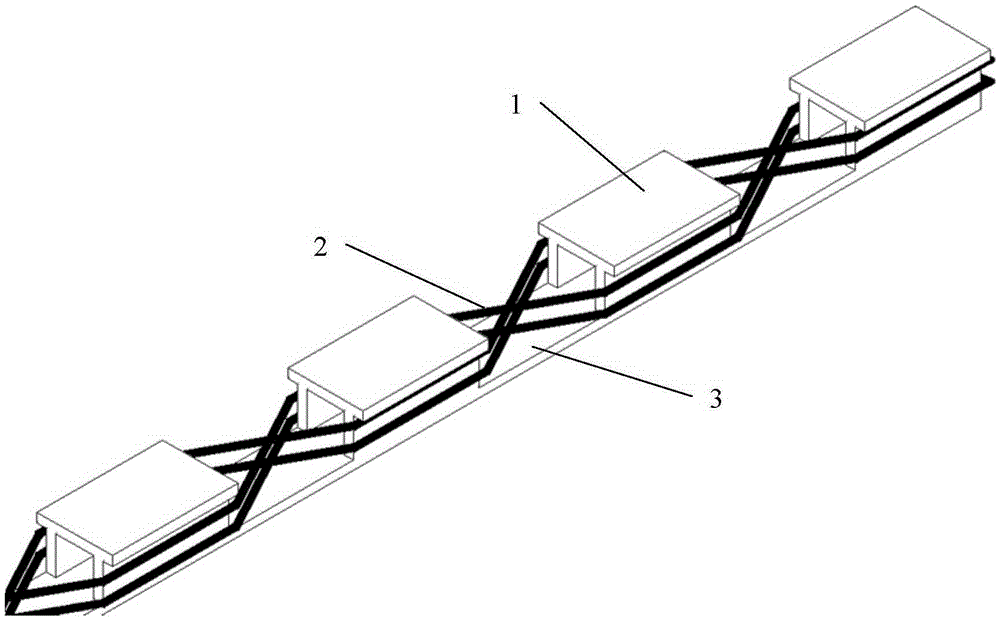

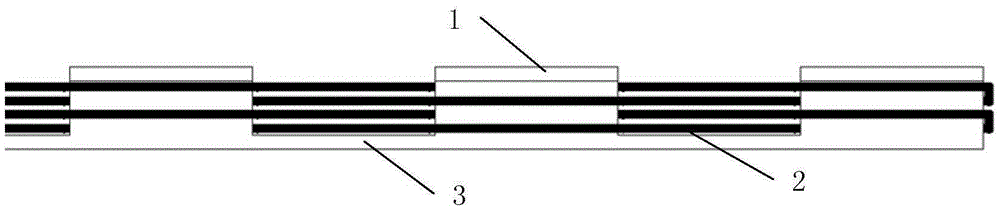

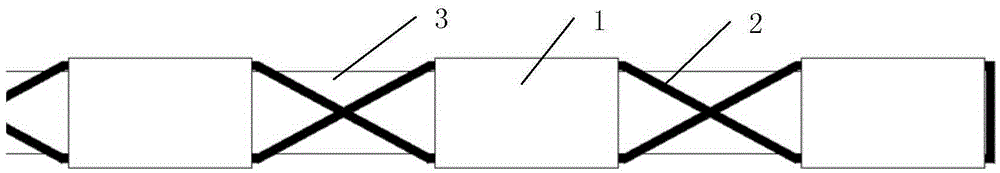

[0023] Specific implementation mode one: refer to Figure 1 to Figure 4 Describe this embodiment in detail. The hollow T-shaped power supply track applied to electric vehicle wireless power supply described in this embodiment includes: at least two magnetic poles 1, power supply cables 2 and magnetic cores 3;

[0024] The magnetic pole 1 is a hollow block with a rectangular cross section, and the two ends of the top side of the rectangle protrude outward at the same time;

[0025] The magnetic core 3 is strip-shaped, and the bottoms of all the magnetic poles 1 are fixed on the magnetic core 3, and all the magnetic poles 1 are arranged in sequence along the length direction of the magnetic core 3, and the distance between two adjacent magnetic poles 1 is equal;

[0026] The width of the bottom of the magnetic pole 1 is equal to the width of the magnetic core 3;

[0027] The power supply cable 2 is divided into a left cable and a right cable. The left cable is wound on all magn...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment further explains the hollow T-shaped power supply rail applied to electric vehicle wireless power supply described in Embodiment 1. In this embodiment, the magnetic pole 1 is a ferrite magnetic pole.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment further explains the hollow T-shaped power supply rail applied to electric vehicle wireless power supply described in Embodiment 1. In this embodiment, the magnetic core 3 is a ferrite core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com