Power distribution method of multilayer printed circuit board PCB, apparatus and PCB thereof

A multi-layer printing and distribution method technology, applied in the direction of printed circuit components, etc., can solve the problems of occupying PCB board area, complex design, multi-area, etc., and achieve the effect of reasonable PCB layout and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

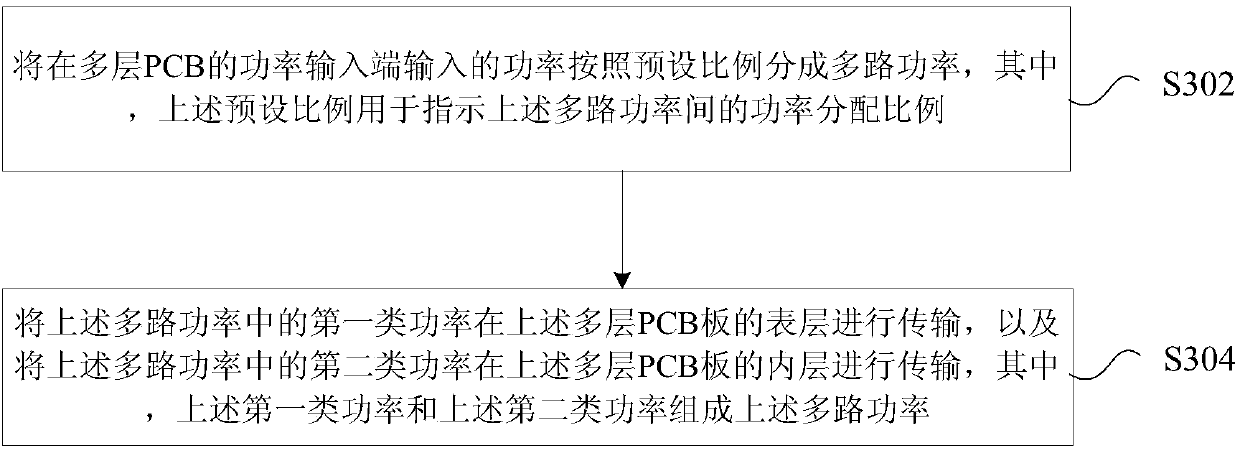

[0026] In this embodiment, a power distribution method in a multilayer PCB is provided, image 3 is a flowchart of a power distribution method in a multilayer PCB according to an embodiment of the present invention, such as image 3 As shown, the process includes the following steps:

[0027] Step S302, divide the power input at the power input terminal of the multilayer PCB into multiple power paths according to a preset ratio, wherein the preset ratio is used to indicate the power distribution ratio among the multiple power paths;

[0028] Step S304, transmitting the first type of power in the above multi-channel power on the surface layer of the above-mentioned multi-layer PCB board, and transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com