Pick-and-place machine

A placement machine, patch technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve problems such as scrap, circuit board paralysis, damage, etc., to reduce scrap problems, reduce paralysis, and reduce scrap rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

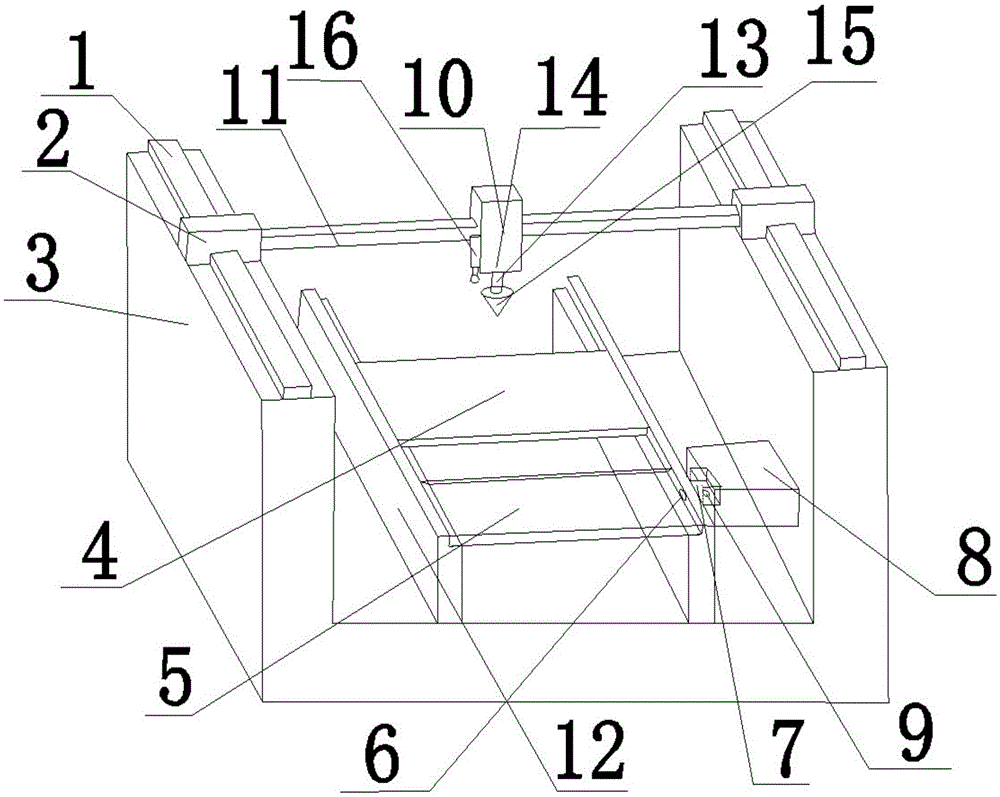

[0013] Such as figure 1 As shown, a placement machine includes a frame 3, a placement mechanism 10, and a transmission mechanism. The transmission mechanism includes an X-Y axis servo positioning mechanism 2, an X-axis track 11 and a Y-axis track 1, and the Y-axis track 1 is arranged on the frame. 3 On both sides, the X-axis track 11 is connected to the Y-axis track 1 through the X-Y axis servo positioning mechanism 2 clamped on the Y-axis track 1, and the patch mechanism 10 is clamped on the X-axis track 11. The patch mechanism 10 includes suction Nozzle 15, the rotating device 13 that is connected with the suction nozzle 15 and can rotate the suction nozzle 15 and the lifting device 14 that can control the lifting of the suction nozzle 15 and the rotation device 13 can realize the arbitrary movement of the suction nozzle 15 in the frame 3, and complete The pick-up of components and the precise placement on the printed circuit board, the placement mechanism 10 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com