Application of lactulose liquid in maintaining good texture of yoghourt within shelf-life

A technology of isomerization and shelf life, applied in the application, dairy products, milk preparations and other directions, can solve the problem of not seeing the tissue state of isomerized lactose liquid, achieve good flavor and taste, good flavor, beneficial to human health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

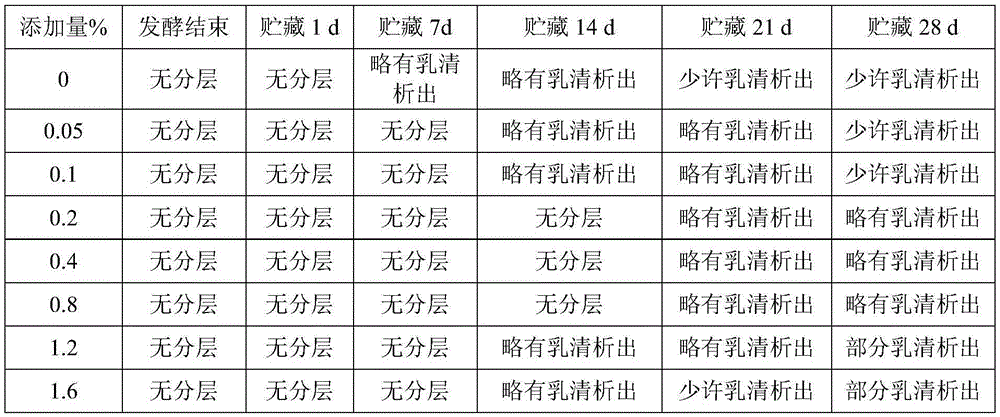

[0035] 1. Prepare drinking yogurt

[0036] The specific formula is as follows:

[0037] Total: 1000g

[0038] White sugar 80g; isomerized lactose liquid 0.5-20g; cream 40g; gellan gum 0.1g; yogurt starter 0.4g; the balance is milk (preferably whole milk).

[0039] Concrete preparation steps:

[0040] 1) After raising the temperature of raw milk to 50-60°C, add isomerized lactose liquid, white sugar, cream and gellan gum, and circulate and stir for 20-30 minutes to obtain the prepared feed liquid;

[0041] 2) Homogenization: Homogenize the above prepared feed solution at 60°C and 18Mpa;

[0042] 3) Sterilization: The homogenized feed liquid is sterilized under the conditions of 93-97°C for 5-10 minutes; then the feed liquid is cooled to 41°C-43°C;

[0043] 4) Inoculation and fermentation: stop the fermentation when the acidity reaches 70-80°T and the pH is about 4.2.

[0044] 5) Secondary homogenization: the homogenization pressure is not greater than 10Mpa, and then fille...

Embodiment 2

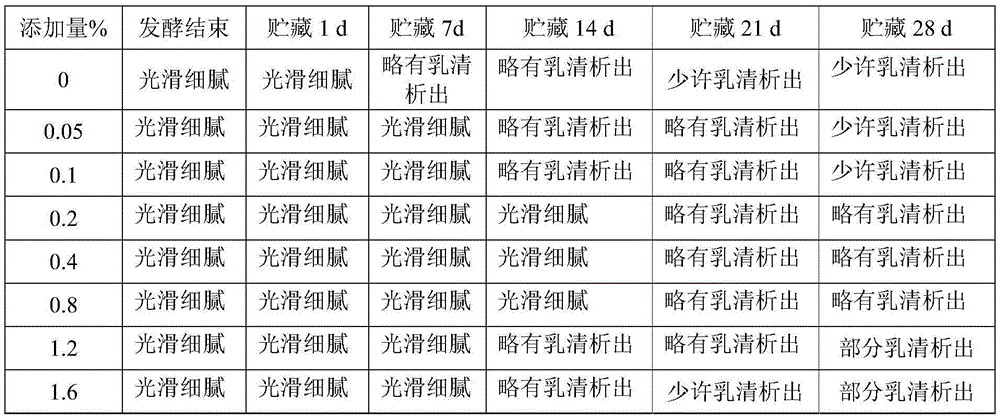

[0083] Stirred yoghurt containing isomerized lactose liquid and production method thereof

[0084] 1. Raw material formula (based on 1000kg)

[0085]

[0086] The isomerized lactose solution was obtained commercially, and the strains used were purchased from Danisco (Beijing) Strains Co., Ltd.

[0087] 2. Specific steps:

[0088] 1) Selection of raw milk: select fresh milk that has passed the inspection, with a protein content ≥ 2.9%, a fat content ≥ 3.1%, and a dry matter content of about 13%;

[0089] 2) After raising the temperature of the raw milk to 50-60°C, add isomerized lactose liquid, white sugar and anhydrous butter, and circulate and stir for 25 minutes to obtain the prepared feed liquid;

[0090] 3) Homogenize the above prepared feed liquid at 60°C and 20Mpa; sterilize the homogenized feed liquid at 95°C for 10 minutes; then cool the feed liquid to 43°C; inoculate and ferment , when the acidity (the above range of temperature and fermentation time is applicab...

Embodiment 3

[0093] A kind of solidified yogurt containing isomerized lactose liquid and its production method

[0094] 1. Raw material formula (based on 1000kg):

[0095]

[0096] 2. Specific steps:

[0097] 1) Selection of raw milk: select fresh milk that has passed the inspection, with a protein content ≥ 2.9%, a fat content ≥ 3.1%, and a dry matter content of about 13%;

[0098] 2) Ingredients: Raise the temperature of the milk to 55°C, add isomerized lactose liquid, modified starch and white sugar, and circulate and stir for 25 minutes to obtain the prepared milk material;

[0099] 3) Preheat the above-mentioned prepared milk material to 70°C for homogenization, the homogenization pressure is 18Mpa; the homogenized material is sterilized at 95°C for 5 minutes; the sterilized material is cooled to 42°C, inoculated and filled Put it in the unit package, then keep the temperature at 42°C, and ferment for 5 hours. When the acidity reaches 70-75°T, the product is cooled to 2-6°C and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com