Pricking preventing infusion needle special for puncture type connecting piece

A connector and anti-needle stick technology, applied in the field of medical devices, can solve the problems of damage to the puncture-type connector seal, no protection or fixing device, no puncture, etc., to reduce the probability of allergies, avoid accidental needle stick injuries, Avoid chipping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

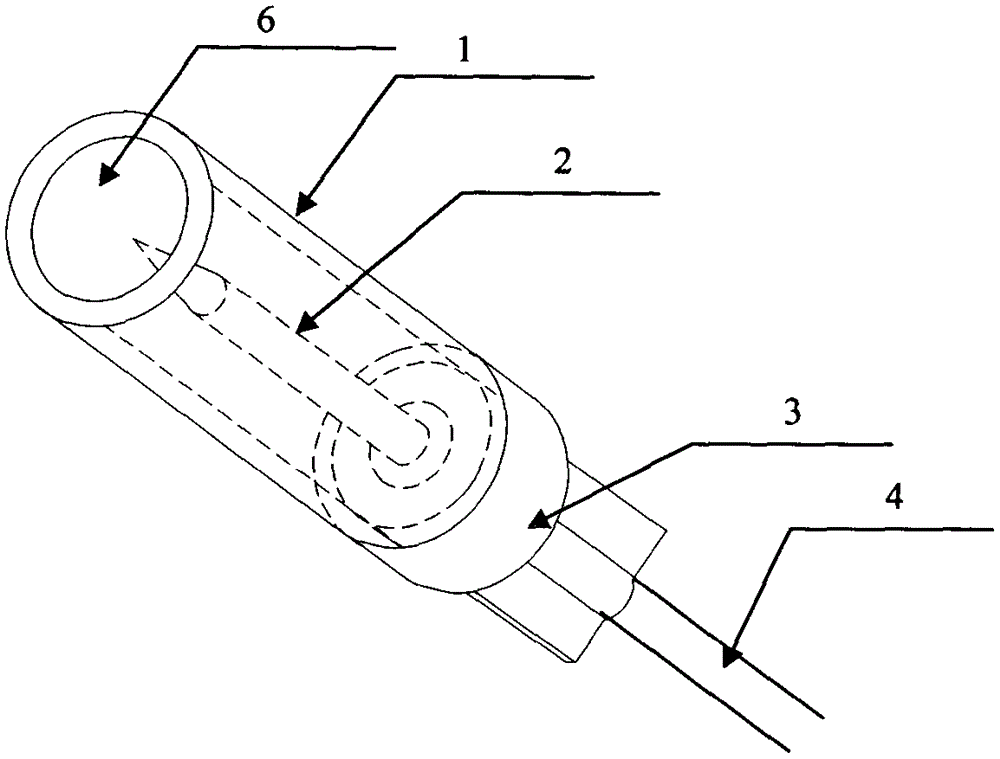

[0042] Example 1: see attached figure 1 shown:

[0043] A special infusion needle for anti-needle puncture-type connectors, including a needle tube 2, a needle base 3, and an infusion catheter 4 connected to the rear end of the needle base 3, the needle tube 2 and the sheath 1 capable of accommodating the puncture-type connector are fixed on the needle base 3 on.

[0044] During production, a sheath 1 with a suitable length is prepared, and the needle hub 3 is bonded to the needle tube 2. After the needle tube 2 is silicified, the sheath 1 is directly sleeved or bonded to the front end of the needle hub 3, so that the entire needle tube 2 is placed in the sheath 1, play the role of anti-acupuncture. In use, the piercing end face of the puncture-type connector enters the bottom of the sheath 1 through the front opening 6 of the sheath 1 , and the puncture-type connector is fixed by using adhesive tape or utilizing the elasticity and friction of the sheath 1 itself. Since the...

Embodiment 2

[0045] Example 2: see attached figure 1 shown:

[0046] A special infusion needle for anti-needle puncture-type connectors, including a needle tube 2, a needle base 3, and an infusion catheter 4 connected to the rear end of the needle base 3, the needle tube 2 and the sheath 1 capable of accommodating the puncture-type connector are fixed on the needle base 3 on. After the puncture-type connector is inserted longitudinally into the sheath 1 , there is a maximum lateral movement distance of 0.5-2.5 mm between the puncture-type connector and the sheath 1 when there is no restriction of the needle tube 2 .

[0047] It is convenient for medical staff to operate, and at the same time, since the puncture-type connector is located in the tubular sheath 1, there is a maximum lateral movement distance of 0.5-2.5 mm between the puncture-type connector and the sheath 1 to prevent the needle tube 2 from repeatedly puncturing the puncture-type connector The center point of the infusion e...

Embodiment 3

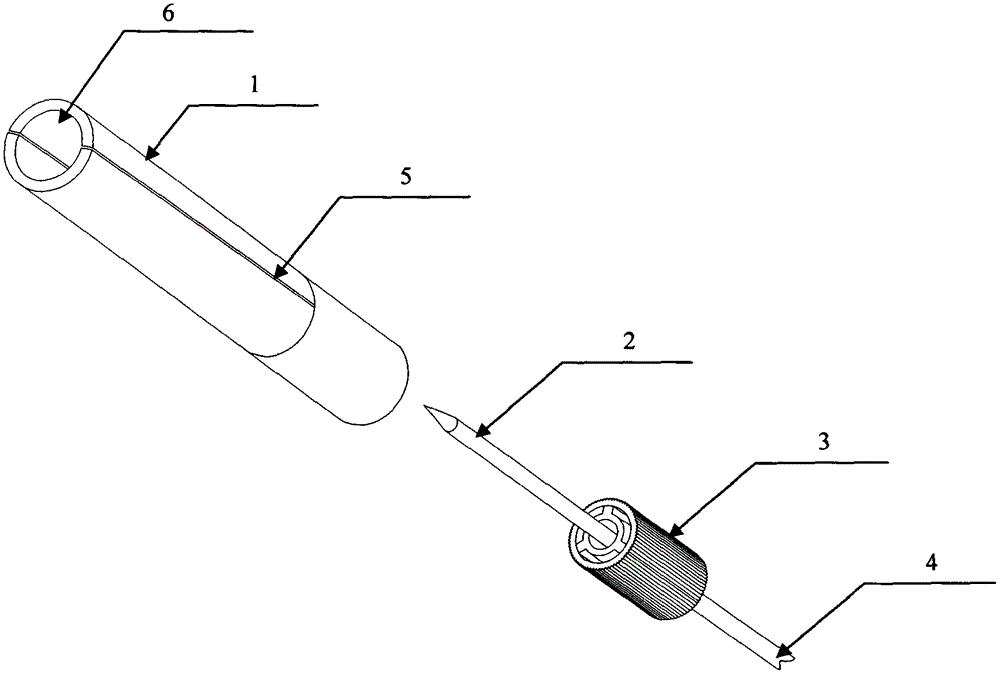

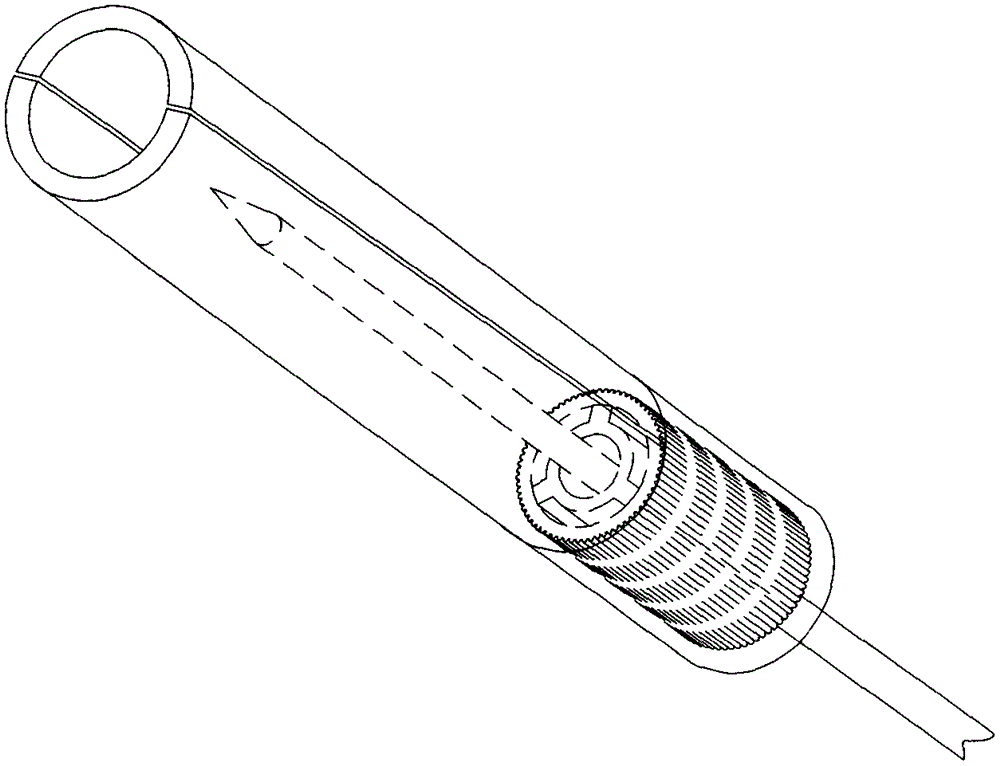

[0048] Embodiment three: see attached figure 2 , 3 shown:

[0049] It includes a needle tube 2 , a needle base 3 , and an infusion catheter 4 connected to the rear end of the needle base 3 . The needle tube 2 and the sheath 1 capable of accommodating a piercing connector are fixed on the needle base 3 . In this example, the sheath 1 is made of soft material, but it has a certain deformation ability and elasticity, and it will not bend during normal use, so it can protect the steel needle and prevent acupuncture. Utilize its deformability plus at least one longitudinal opening 5 to ensure that it can accommodate piercing connectors within a certain range of deviation from the axis of the needle tube 2 or various specifications and piercing connectors on the Y-shaped indwelling needle.

[0050] During production, the sheath 1 can be prepared using an extruder, and the opening 5 can be punched out using a knife.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com