Seamless steel tube bending machine

A technology of seamless steel pipe and pipe bending machine, which is applied in the field of pipe bending machines, can solve the problems of low efficiency of seamless steel pipe pipe bending, and achieve the effects of simple structure, high pipe bending precision, and prevention of collapse and inner wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

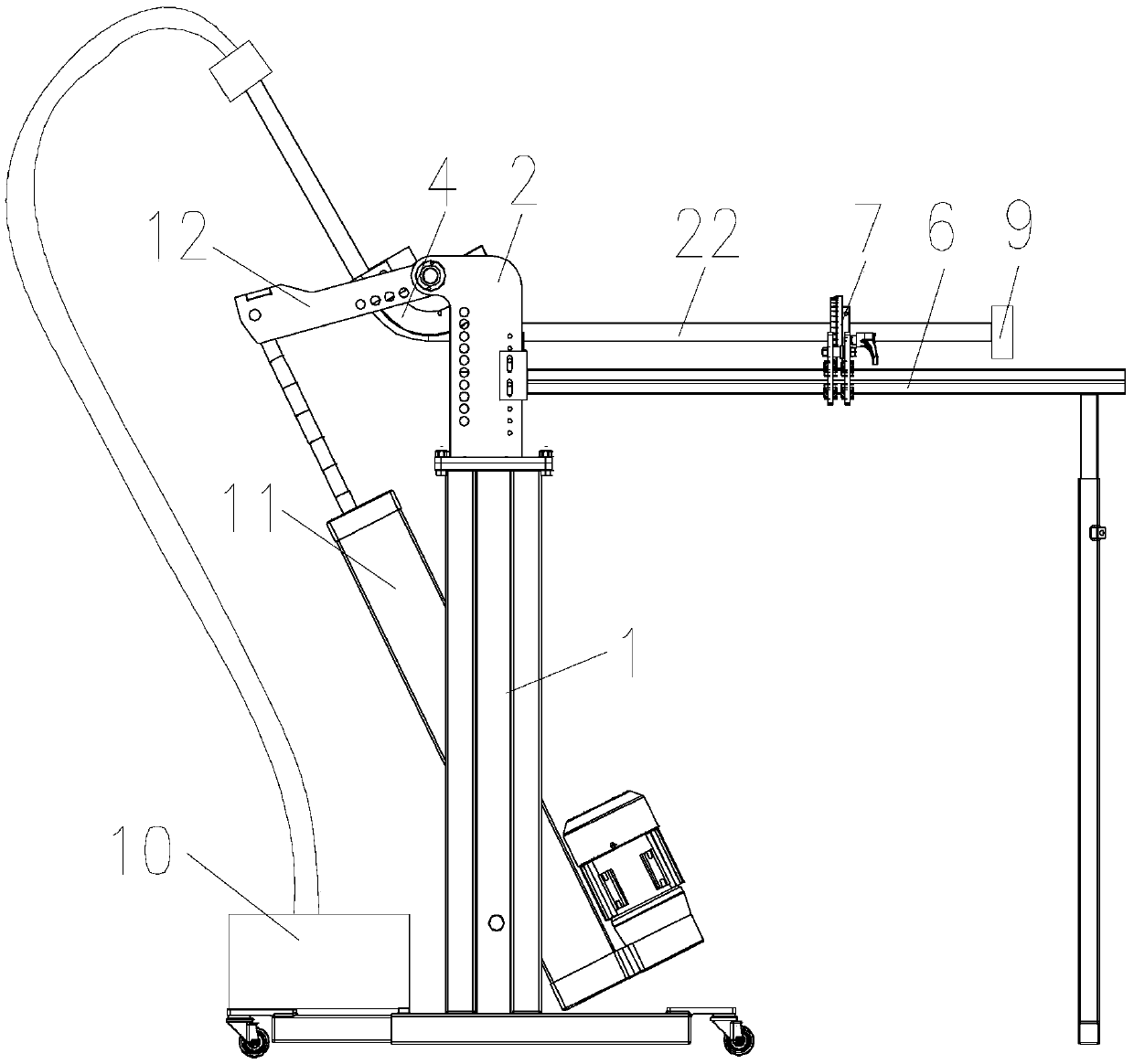

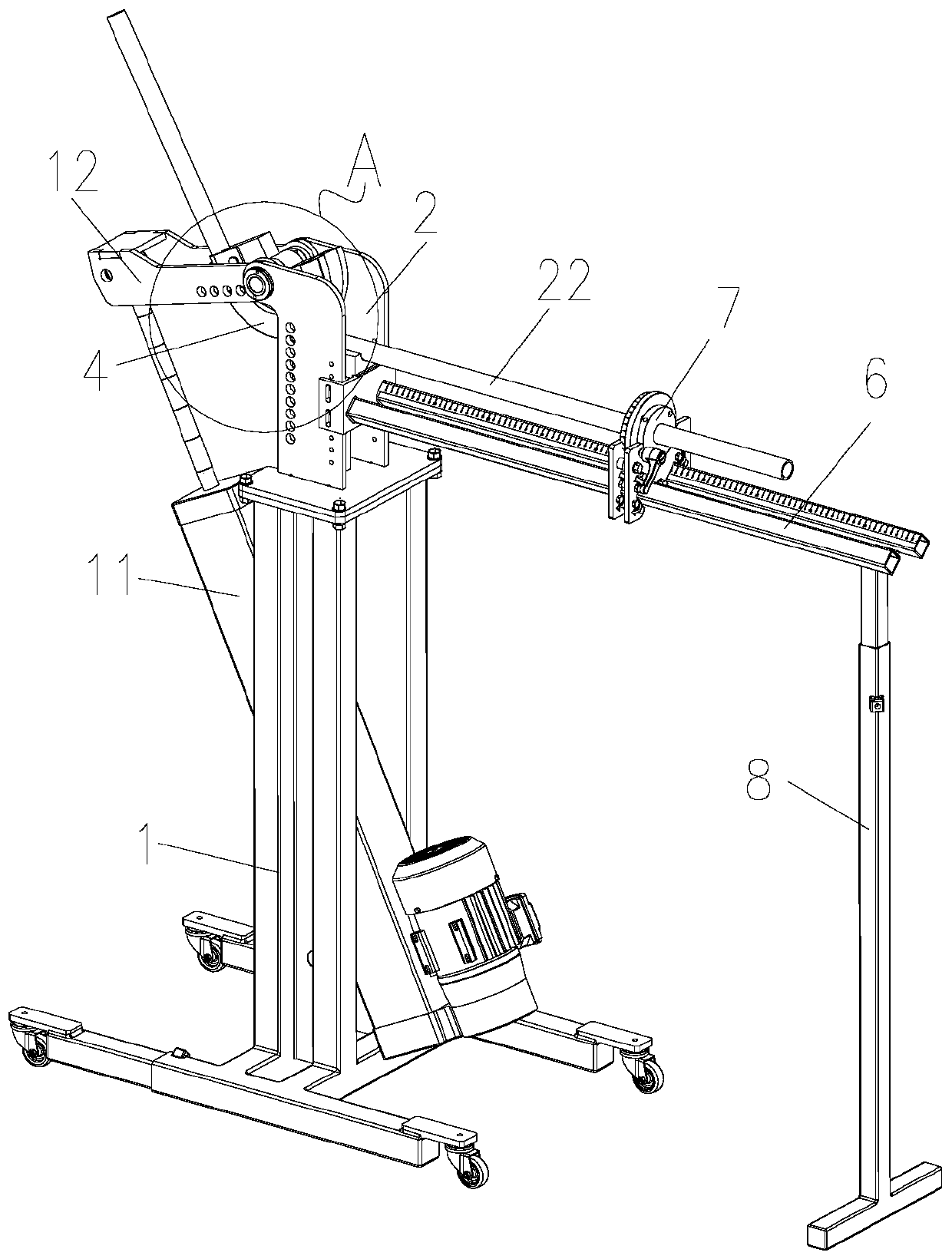

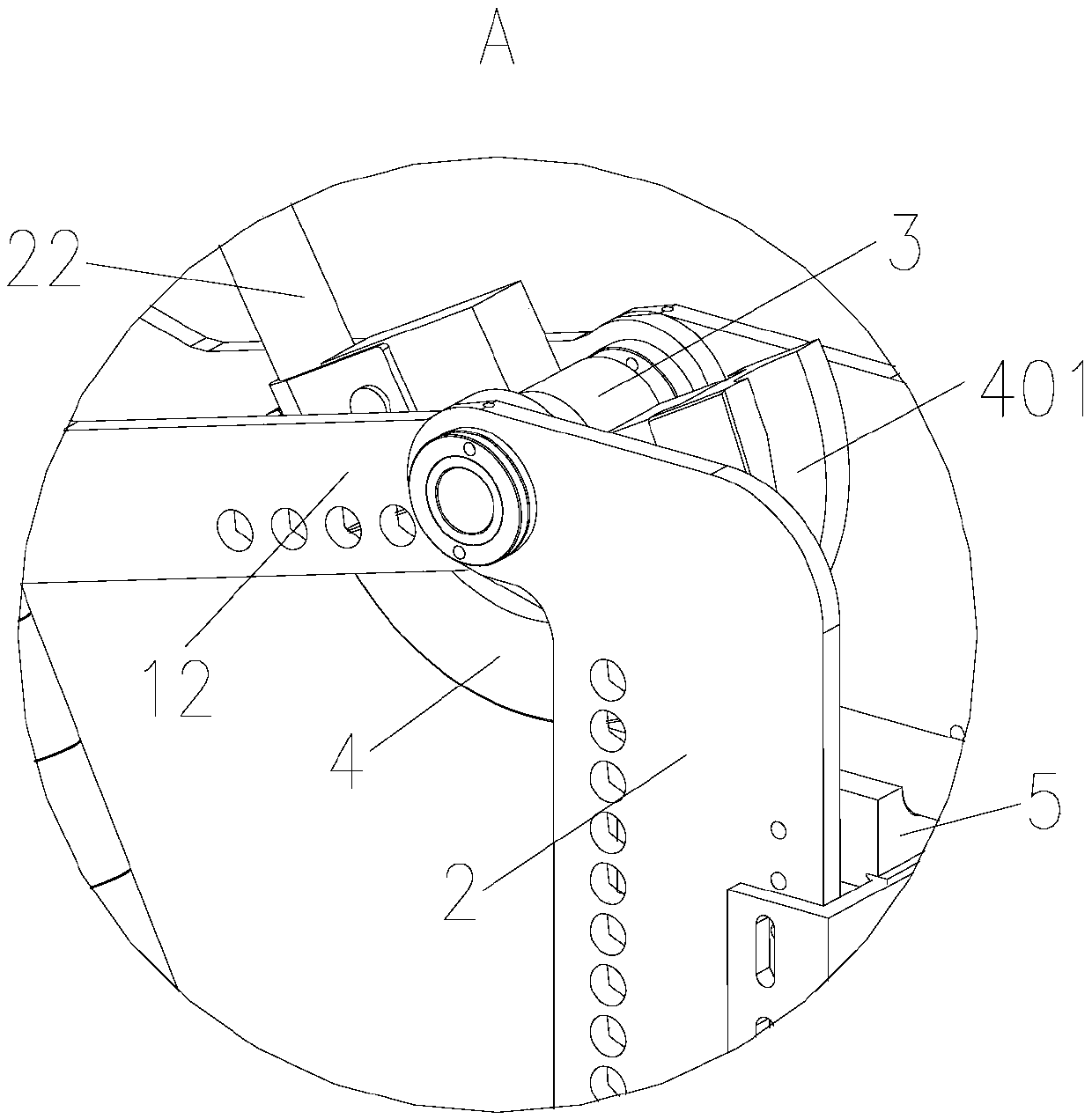

[0022] As shown in Figures 1-6, a seamless steel pipe bending machine includes a frame 1 and two side wings 2 arranged on the frame 1, and a rotating block 3 is connected between the side wings 2, and the rotating The block 3 is detachably connected with a semicircular pipe bending die 4, the circumferential surface of the pipe bending die 4 is provided with a pipe bending groove 401 matching the seamless steel pipe 22, and the frame 1 is provided with a The driving mechanism for the rotation of the rotating block 3, the bottom of the rotating block 3 is provided with a supporting plate 5, the supporting plate 5 is provided with a bracket 501 matched with the seamless steel pipe 22, and the supporting plate 5 is provided with a bracket for The power device that drives it to rise or fall, the rotating block 3 is provided with a clamping mechanism for clamping the seamless steel pipe 22 on the pipe bending die 4, and the side of the wing 2 is provided with a slide frame 6, so A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com