Novel gear rolling machine

A gear rubbing machine, a new type of technology, applied to gears, other household appliances, household appliances, etc., can solve the problem of inconvenient tool replacement, and achieve the effects of convenient tool change, high work efficiency, and simple loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

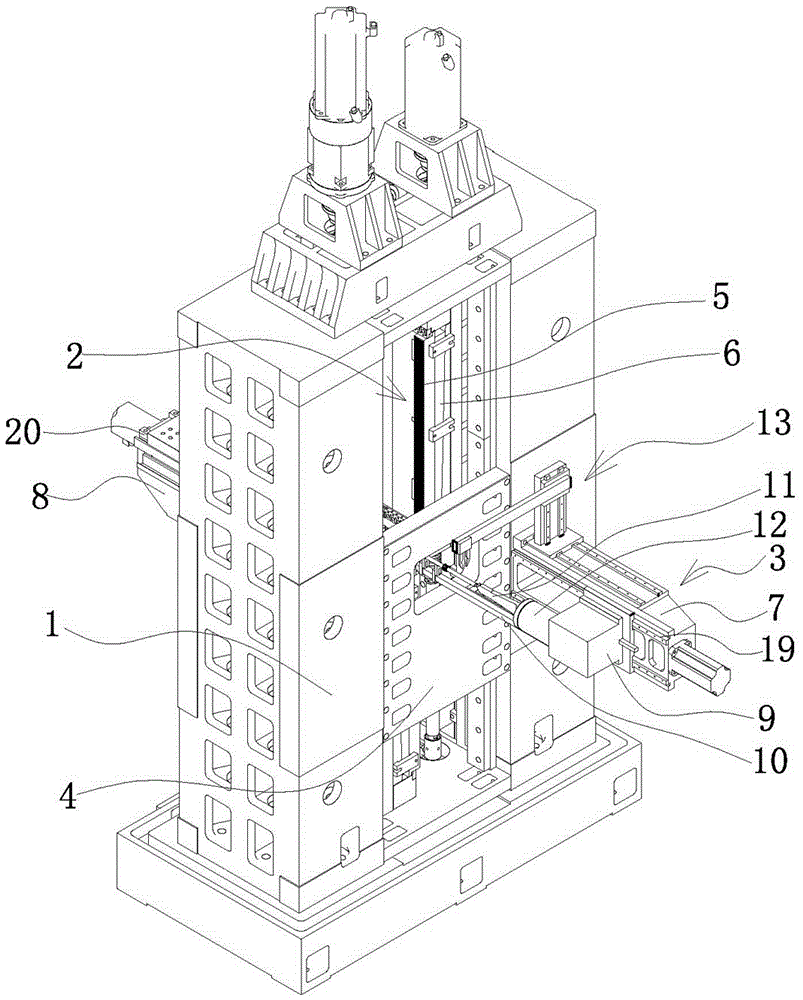

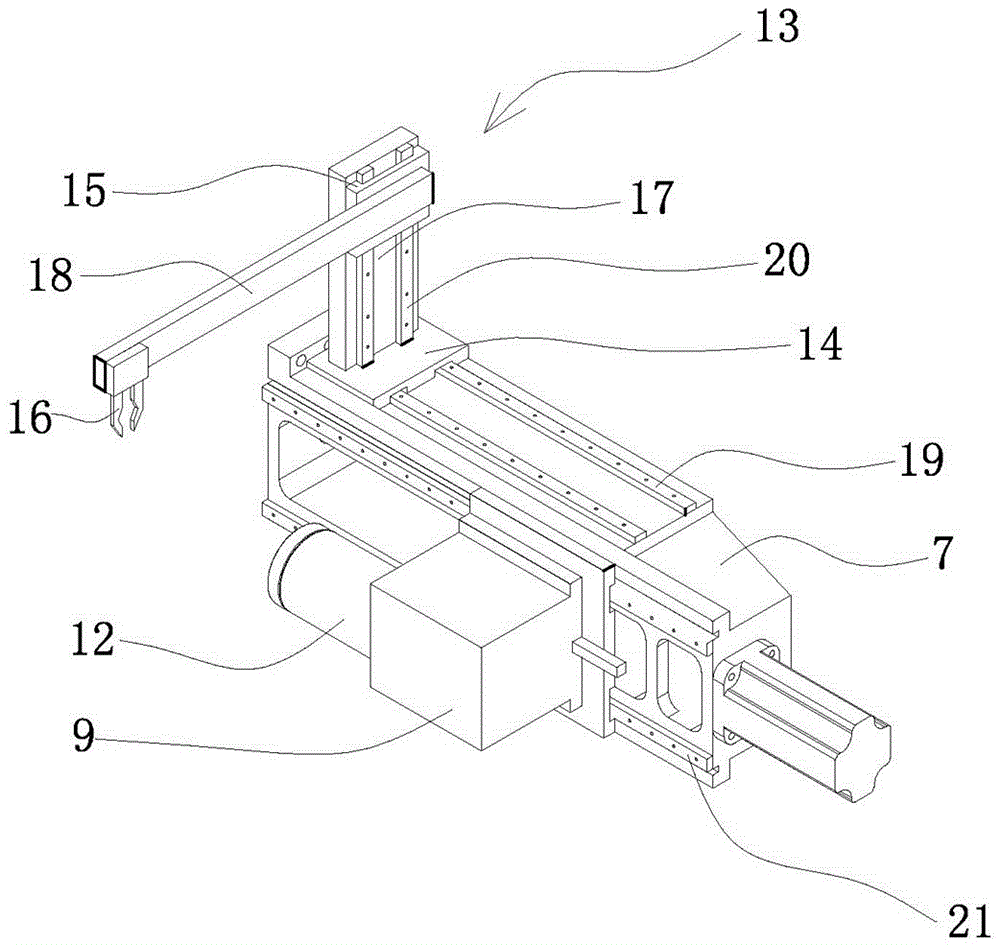

[0016] Such as figure 1 , figure 2 As shown, the new gear rubbing machine includes a bed 1, a gear rubbing mechanism 2 and a feeding mechanism 3 arranged in the bed 1, a safety door 4 is arranged on the front and rear surfaces of the bed 1, and the gear rubbing mechanism 2 includes a gear rubbing plate 5 and the reference plate 6, the feeding mechanism 3 passes through the two safety doors 4 on the front and rear surfaces of the bed 1 and is located between the gear rubbing mechanism 2, the feeding mechanism 3 includes a front sliding saddle 7, a rear sliding saddle 8 and the front and rear saddles respectively The sliding table 9 on the sliding saddle 7 and the rear sliding saddle 8, the front sliding saddle 7 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com