Switching three-way valve wrench

A wrench head and handle technology, which is applied in the direction of wrenches, manufacturing tools, wrench, etc., can solve the problems of opening and closing of high-speed combined valves, so as to solve the difficulty of opening and closing, shorten the time-consuming, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

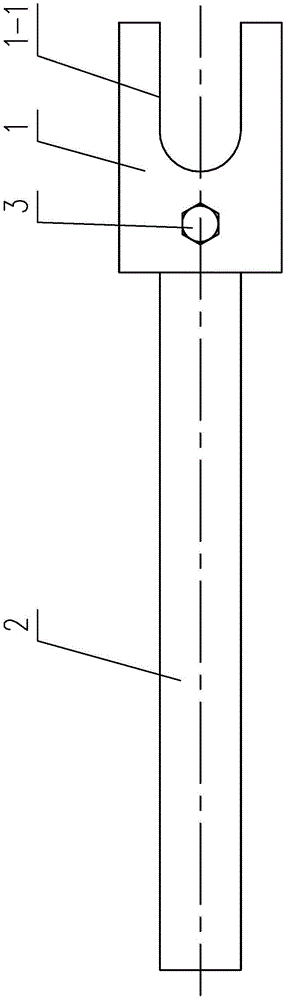

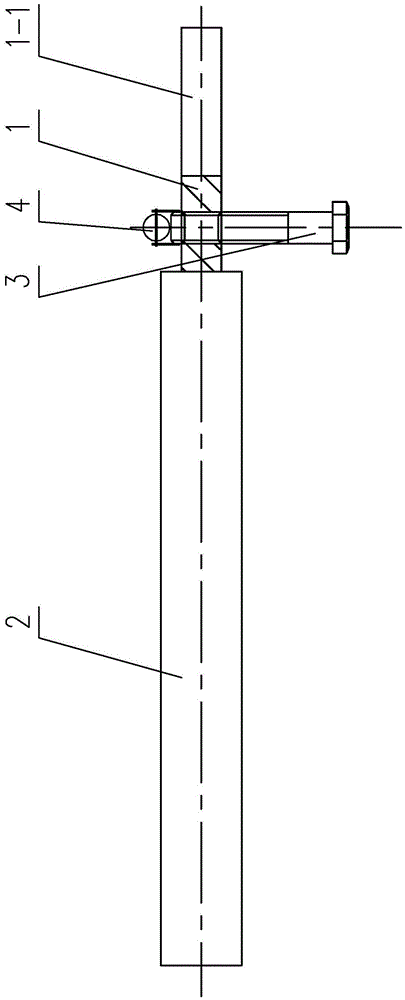

[0010] Specific implementation mode one: combine figure 1 and figure 2 Explain that a high-speed valve wrench described in this embodiment includes a wrench head 1, a handle 2 and an adjustment bolt 3. The wrench head 1 is fixedly connected to the front end of the handle 2, and the front end of the wrench head 1 is provided with a U-shaped through groove 1 -1, the notch of the U-shaped through groove 1-1 is arranged in the middle part of the front end of the wrench head 1, and the middle part of the rear end of the U-shaped through groove 1-1 is provided with an adjusting bolt 3, and the axis direction of the adjusting bolt 3 is aligned with the direction of the wrench head 1. The front side is vertical.

[0011] In such a design, the U-shaped channel 1-1 of the connecting valve wrench is stuck in the annular groove on the top of the valve stem, and the lower end of the adjusting bolt 3 is stuck on the connecting valve housing, and the use height of the wrench is controlled ...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 and figure 2 It is explained that the end of the adjustment bolt 3 in this embodiment is hinged with a roller 4 . Other compositions and connection methods are the same as those in Embodiment 1.

[0013] Such a design can reduce the friction between the adjusting bolt 3 and the connecting valve casing, thereby reducing resistance and improving work efficiency.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 and figure 2 Note that the depth of the U-shaped through groove 1-1 in this embodiment is 40mm, and the groove width of the U-shaped through groove 1-1 is 28mm. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0015] It is designed in this way to match the commonly used external dimensions of high-addition valves. In actual application, it can be adjusted according to the external dimensions of different high-addition valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com