Excavator steering drive axle

A technology for steering drive axles and excavators, applied in the directions of axles, wheels, control devices, etc., can solve the problem of reducing the transmission torque and service life of the planetary reduction mechanism, dislocation meshing of the sun gear and planetary gear sets on different axes, affecting the planetary reduction mechanism. Service life and other issues, to achieve the effect of increasing output torque, reducing assembly process requirements, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

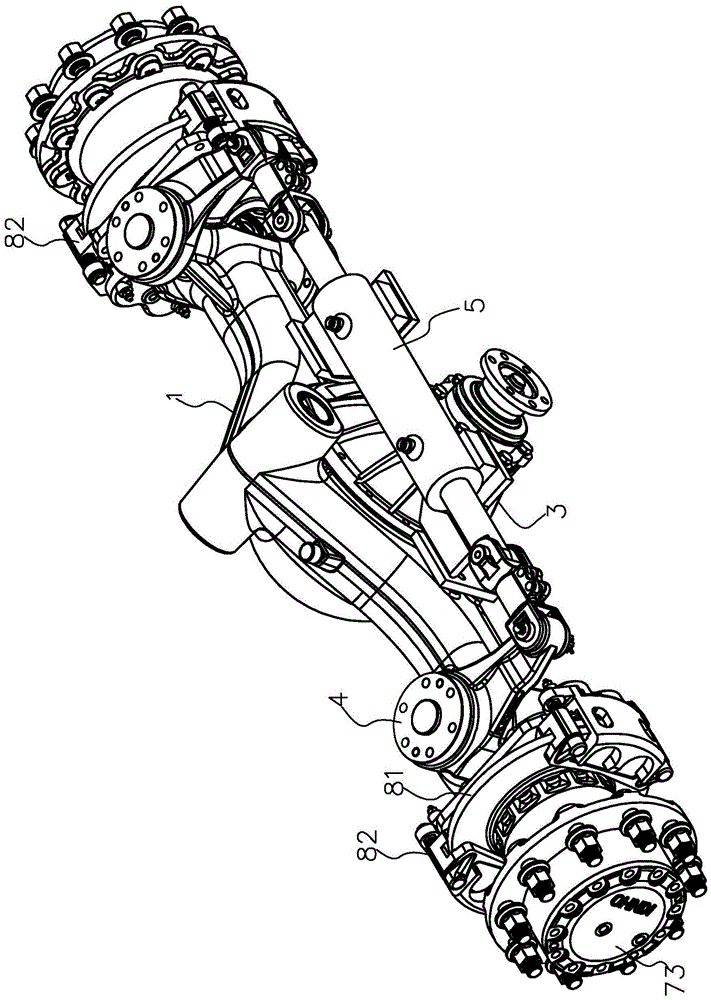

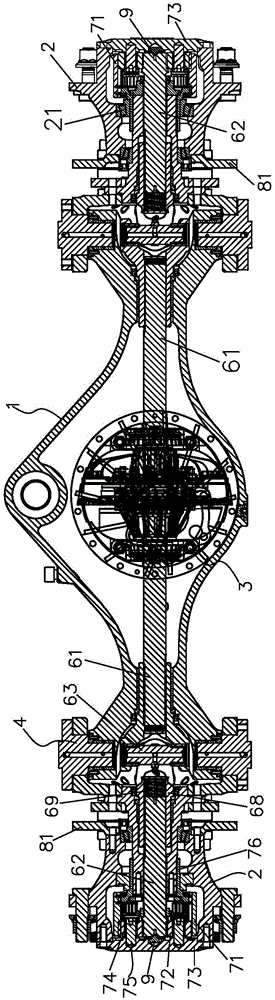

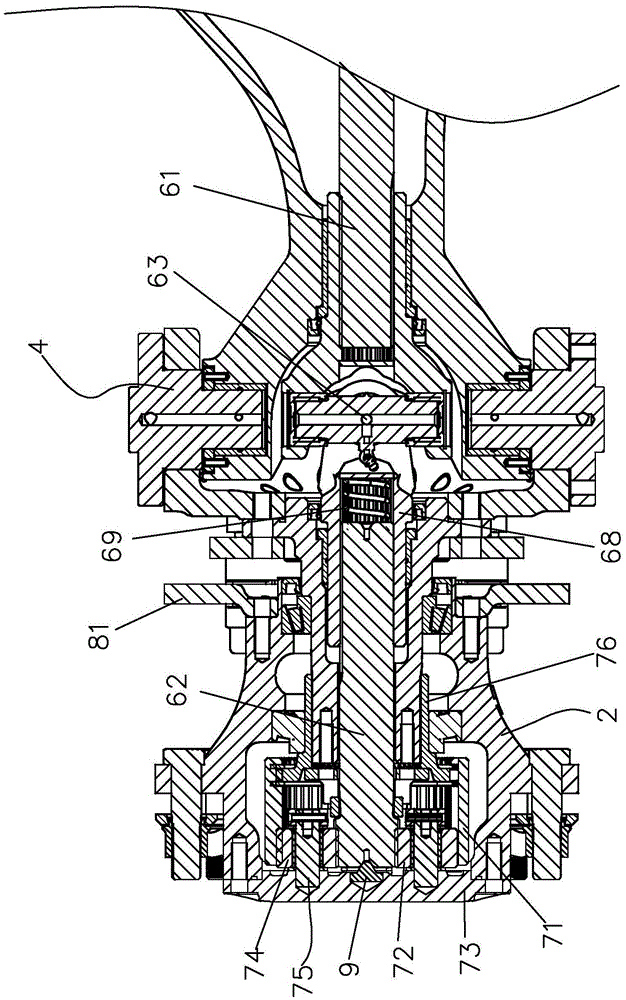

[0018] Such as Figure 1 to Figure 4 , the present invention discloses an excavator steering drive axle, comprising an axle housing 1, two braking devices, two hubs 2, a transmission device and a steering device, the axle housing 1 is approximately axially extending and has a hollow structure, and the transmission The device includes two parts, the final drive 3 (including the differential) and the universal drive. The final drive 3 is located in the middle of the inner side of the axle housing 1 to convert the radial torque input of the engine into an axial torque output. The devices are respectively installed on the hubs 2 at both ends of the axle housing 1 to control the rotation of the hubs 2. The two hubs 2 are rotatably installed at both ends of the axle housing 1 through bearings 21. The axial torque of the reducer 3 is respectively out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com