Automatic lift type drug pressing device

An automatic lifting and pressing technology, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of large manpower consumption, affecting work efficiency, and potential safety hazards, so as to save labor costs, improve reliability, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but it does not constitute a limitation of the present invention, and is only used as an example. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

[0032] like Figure 1 to Figure 6 The process of pressing the drug column by the drug pressing device in the prior art shown has been introduced in detail in the background art, and will not be repeated here.

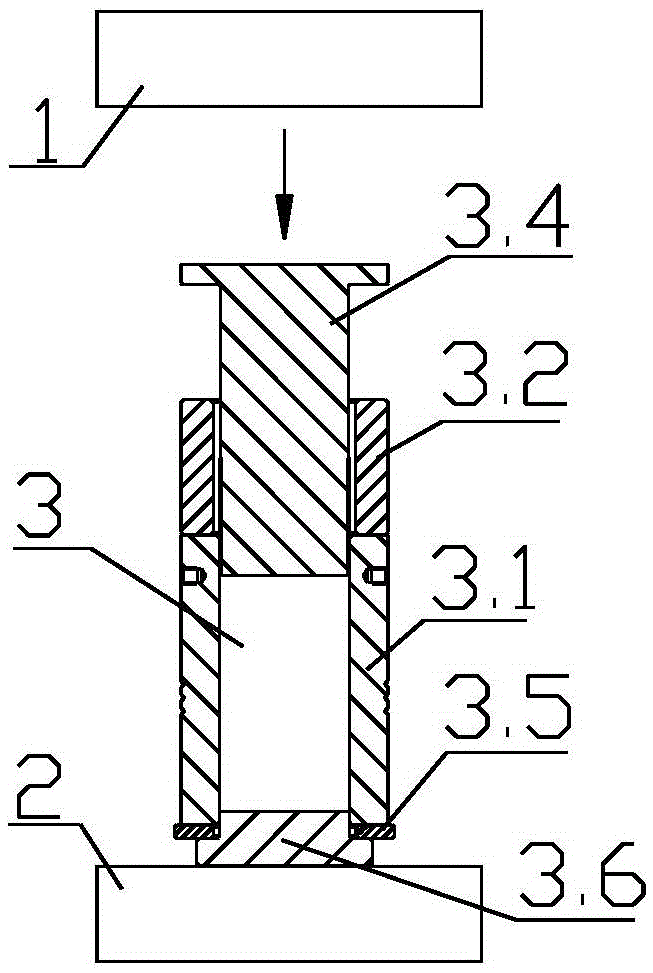

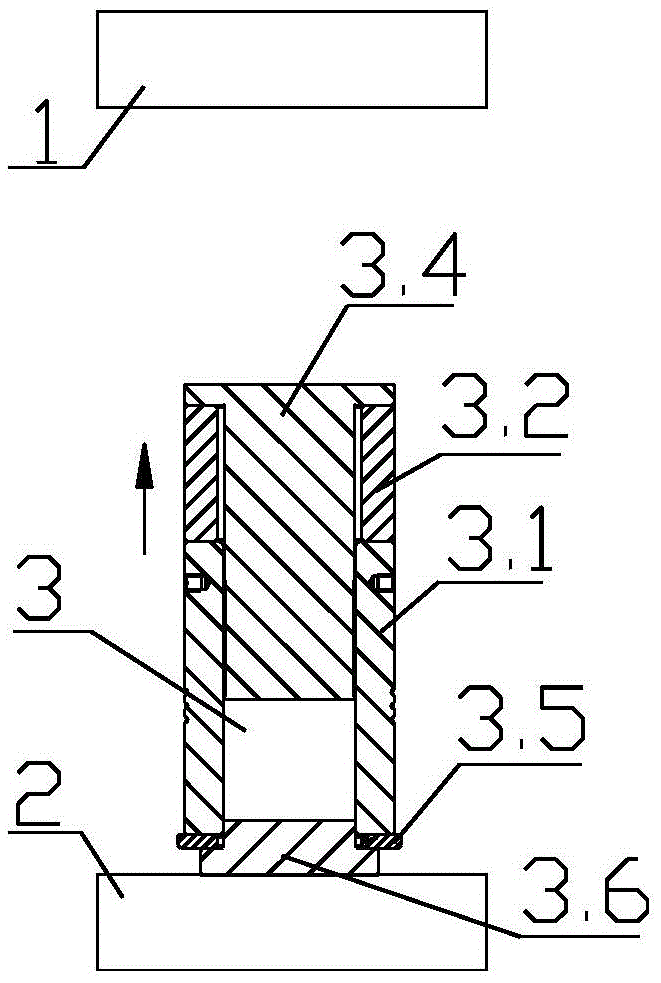

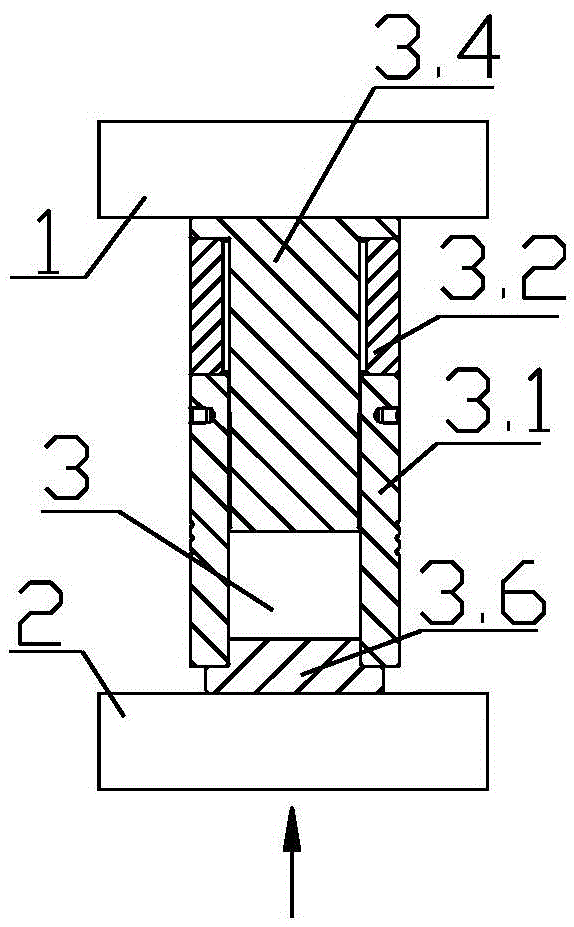

[0033] like Figure 7 to Figure 11 As shown, in the present invention, the medicine pressing mold 3 is located on the lower briquetting block 2 of the press machine, and above the medicine pressing mold 3 is the upper briquetting block 1 corresponding to the lower briquetting block 2 . Two grooves are arranged symmetrically on the lower part of the upper pressing block 1, and two mechanical arms 4 are vertically ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com