Preparation method of polyethylene special material for vehicle decorative non-woven fabric back glue

A technology of polyethylene and cloth adhesive, applied in the field of polymer synthesis, to achieve the effect of easy operation, narrow molecular weight distribution and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

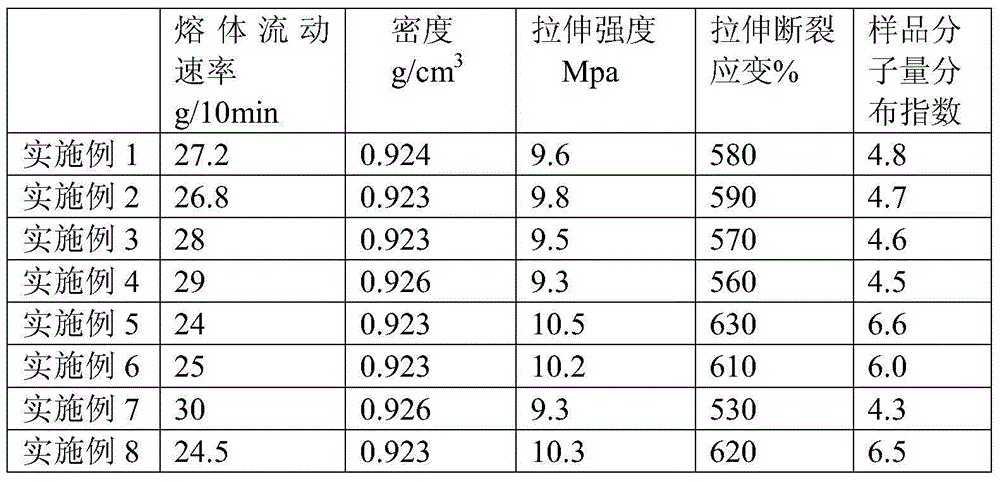

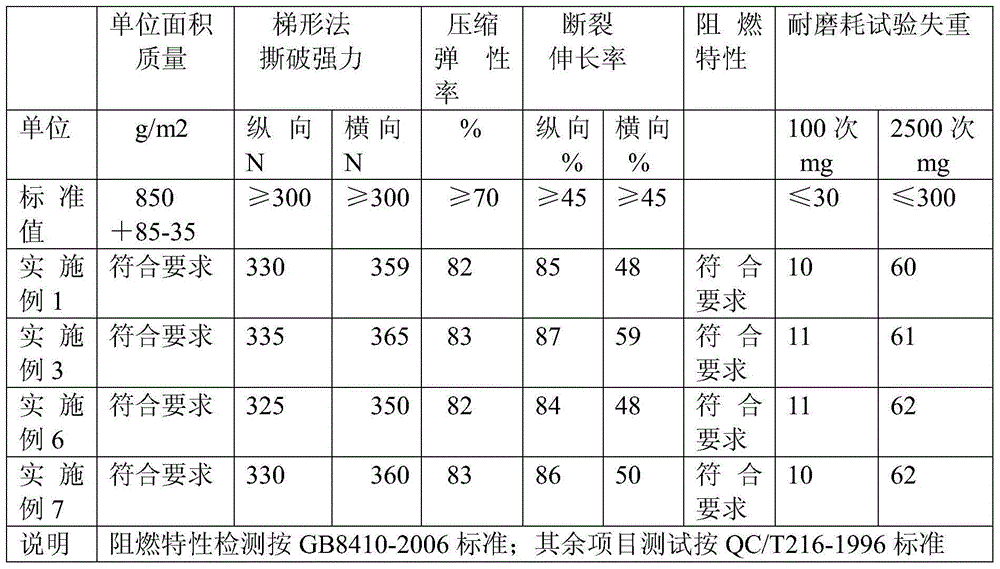

Examples

Embodiment 1

[0022] (1) Compress ethylene, the first initiator, the second initiator and the adjustment agent, and after compression, be divided into two main and side flow feed gases whose pressure is 230-250Mpa; the main flow feed gas includes ethylene, First initiator and adjustment agent, the content of the tert-butyl peroxyneodecanoate in the described first initiator is 1ppm, and the content of tert-butyl peroxide 2-ethylhexanoate is 4ppm, and described adjustment agent is Propionaldehyde, the content of propionaldehyde is 225ppm; Described side stream feed gas comprises ethene and second initiator, and described second initiator is compressed air through filtering and drying, and its content is 16ppm;

[0023] (2) The main feed gas enters the first tubular reactor, and is first gradually heated to 175±10°C with a steam jacket, and then polymerized in the reaction zone. The polymerization temperature is 310-330°C, and the pressure is 240-250Mpa. The reaction time is 7 to 8 seconds; a...

Embodiment 2

[0026] Concrete steps are with embodiment 1.

[0027] Among them: the main and side feed gas pressures are 230-245Mpa, the first initiator in the main feed gas, the content of tert-butyl peroxyneodecanoate is 1.1ppm, and the content of tert-butyl peroxide 2-ethylhexanoate The content of butyl fat is 4.4ppm, the initiator compressed air content in the side stream feed gas is 17ppm, the molecular weight regulator propionaldehyde content in the mainstream feed gas is 225ppm, and the reaction temperature of the first tubular reactor is controlled to be 310~ 320°C, the reaction temperature of the second tubular reactor is controlled at 310-320°C.

Embodiment 3

[0029] Concrete steps are with embodiment 1.

[0030] Among them: the main and side feed gas pressures are 230-240Mpa, the first initiator in the main feed gas, the content of tert-butyl peroxyneodecanoate is 0.95ppm, and the content of tert-butyl peroxyneodecanoate is 0.95ppm, The content of butyl fat is 3.8ppm, and the second initiator (compressed air) content in the side stream feed gas is 16ppm, and the content of regulator propionaldehyde in the mainstream feed gas is 225ppm, and the reaction temperature of the first tubular reactor The temperature is controlled at 300-310°C, and the reaction temperature of the second tubular reactor is controlled at 300-310°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com