A kind of knitting process of steel wire pantyhose

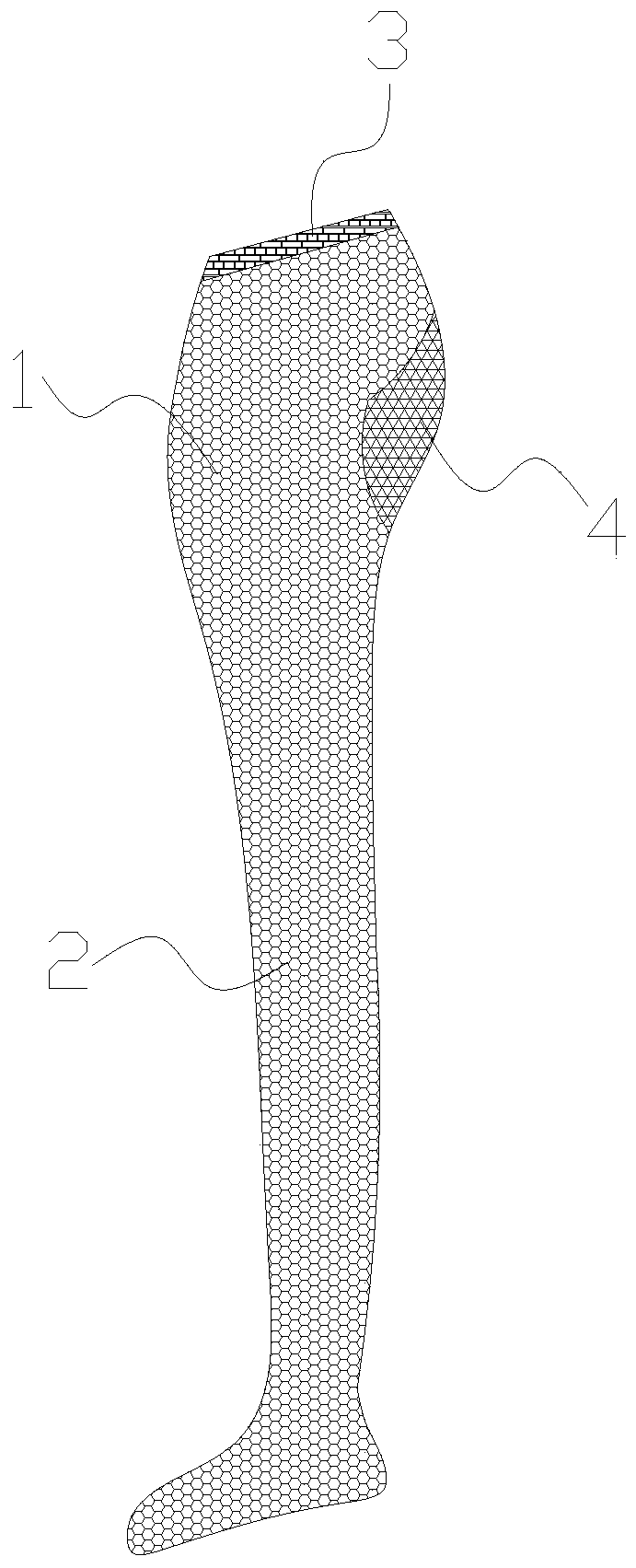

A steel wire pantyhose and craft technology, applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of not feeling comfortable enough, easy to slip down from the waist, and the upper end of the trousers is loose, so that it is not easy to snag and pill , good hip lifting and shaping effect, not easy to relax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

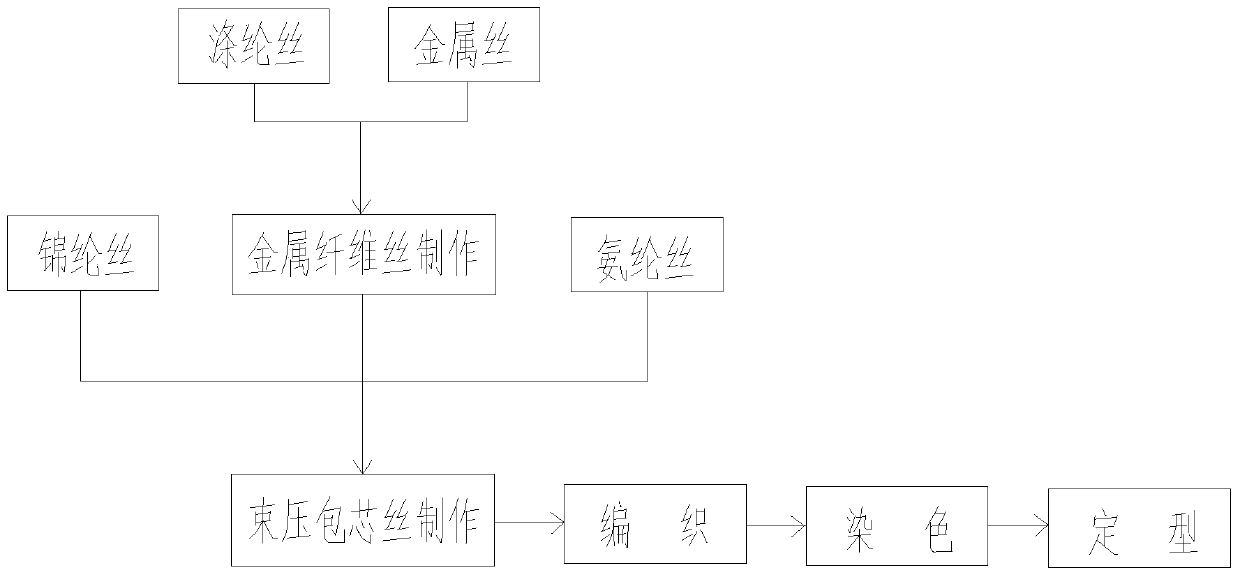

[0025] A weaving process for producing steel wire pantyhose, which comprises the following steps:

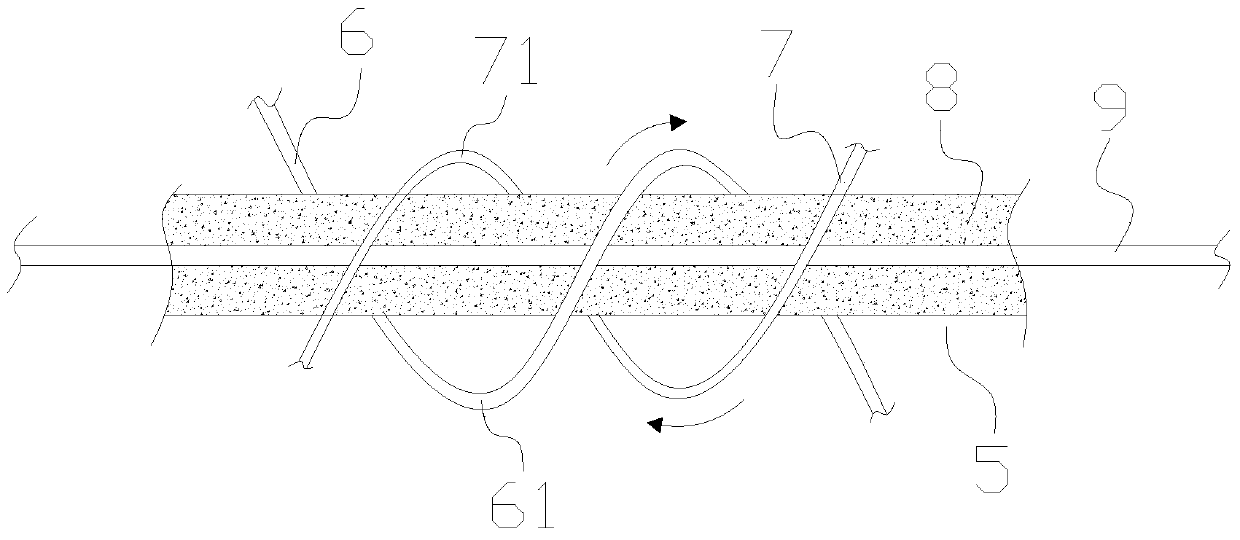

[0026] 1), the production of metal fiber filaments, using nano-scale metal wires as the inner core, then spinning 15D / 1F polyester filaments and wrapping them on the nano-scale metallic filaments, and controlling the tension of the polyester filaments at 1.2 grams to produce Metal fiber filament with a twist of 1800T / M and a draft ratio of 2.5;

[0027] 2), beam pressing core yarn production, the metal fiber yarn made in step 1) is used as the inner yarn, and its tension is controlled at 2.0 grams, and then the nylon yarn and the spandex yarn as the outer yarn are passed through a high-speed wrapping machine according to the Two different helical directions, positive and negative, are wrapped on the metal fiber filaments to produce bundle cored filaments with a twist of 2400T / M and a draft ratio of 3.5;

[0028] 3) Weaving, the nylon and covered yarns are first fed into the kni...

Embodiment 2

[0032] A weaving process for producing steel wire pantyhose, which comprises the following steps:

[0033] 1), the production of metal fiber filaments, using nano-scale metal wires as the inner core, then spinning 15D / 1F polyester filaments around the nano-scale metal filaments, and controlling the tension of the polyester filaments at 1.6 grams to produce Metal fiber filaments with a twist of 1500T / M and a draft ratio of 2.0;

[0034] 2), beam pressing core yarn is made, the metal fiber yarn made in step 1) is used as the inner yarn, and its tension is controlled at 1.5 grams, and then the nylon yarn and spandex yarn as the outer yarn are passed through the high-speed wrapping machine according to the Two different helical directions, positive and negative, are wrapped on the metal fiber filaments to produce bundle cored filaments with a twist of 2000T / M and a draft ratio of 3.0;

[0035] 3) Weaving, the nylon and covered yarns are first fed into the knitting machine at the ...

Embodiment 3

[0039] A weaving process for producing steel wire pantyhose, which comprises the following steps:

[0040] 1), the production of metal fiber filaments, using nano-scale metal wires as the inner core, then spinning 15D / 1F polyester filaments and wrapping them on the nano-scale metallic filaments, and controlling the tension of the polyester filaments at 1.4 grams to produce The twist is 1650T / M, and the draft ratio is set to be 2.25 metal fiber filaments;

[0041] 2), beam pressing core yarn production, the metal fiber yarn made in step 1) is used as the inner yarn, and its tension is controlled at 1.75 grams, and then the nylon yarn and the spandex yarn as the outer yarn are passed through a high-speed wrapping machine according to the Two different helical directions, positive and negative, are wrapped on the metal fiber filaments to produce bundle-pressed cored filaments with a twist of 2200T / M and a draft ratio of 3.25;

[0042]3) Weaving, the nylon and covered yarns are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com