Pier energy-dissipating and crushing-preventing structure internally provided with energy dissipating steel plates and viscous-elastic material layers

A technology of crushing structures and material layers, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of increased residual deformation of bridge piers, easy crushing of bottom segments, and difficult replacement of energy-consuming steel bars, so as to increase energy consumption capacity , Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

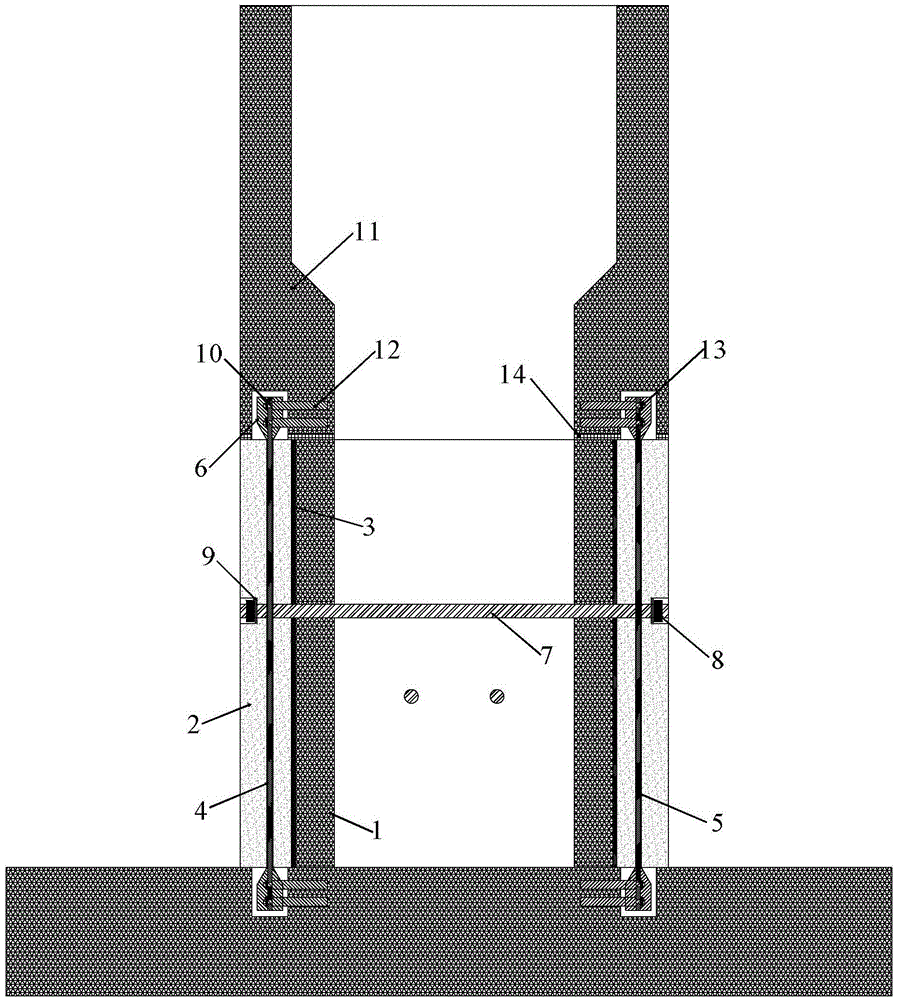

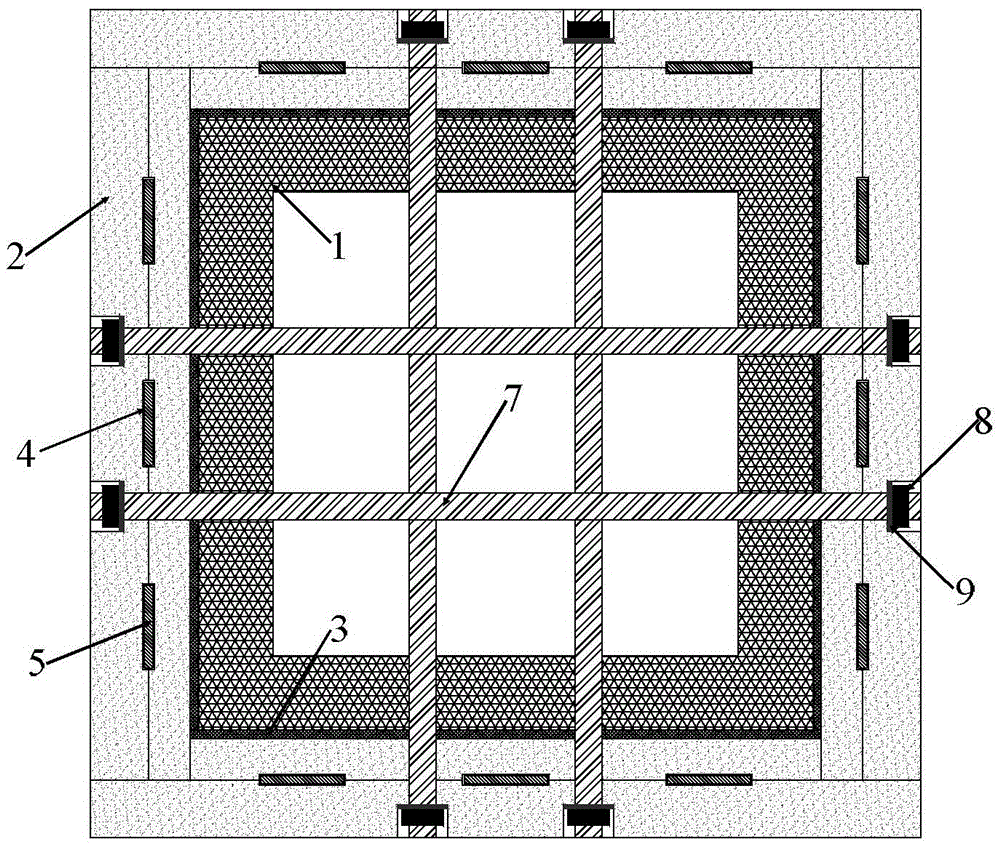

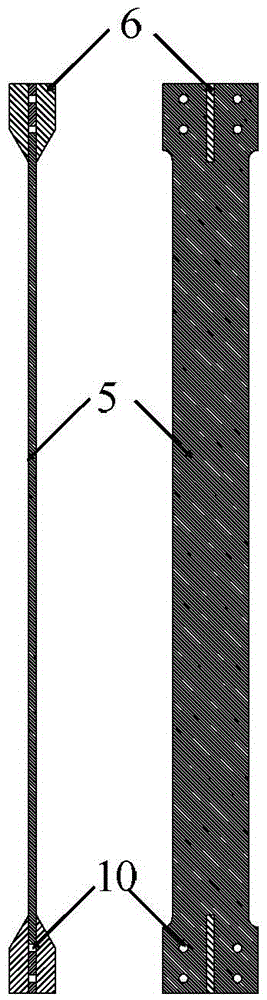

[0022] The present invention is a structure that improves the energy dissipation capacity of dry joint section assembled bridge piers under earthquake excitation and prevents the bottom section from being crushed by using replaceable UHPC plates with built-in energy dissipation steel plates and viscoelastic material layers. It is necessary to use replaceable UHPC plates, viscoelastic material layers, energy-dissipating steel plates, precision-rolled threaded steel bars, nuts, high-strength nuts, steel gaskets, embedded steel rods, and rubber cushions.

[0023] The replaceable UHPC boards are respectively provided with two pieces on the four sides of the bottom section of the pier, and a viscoelastic material layer is arranged between the UHPC board and the bottom section of the pier, and the viscoelastic material layer and the UHPC board are connected by cementation, and connected with the bottom section of the pier. The force is transmitted between the sections through frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com