Motor driven transfer case with modular actuation

A gearbox and actuation technology, applied in the direction of vehicle gearbox, transmission, transmission control, etc., can solve problems such as complex gearbox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

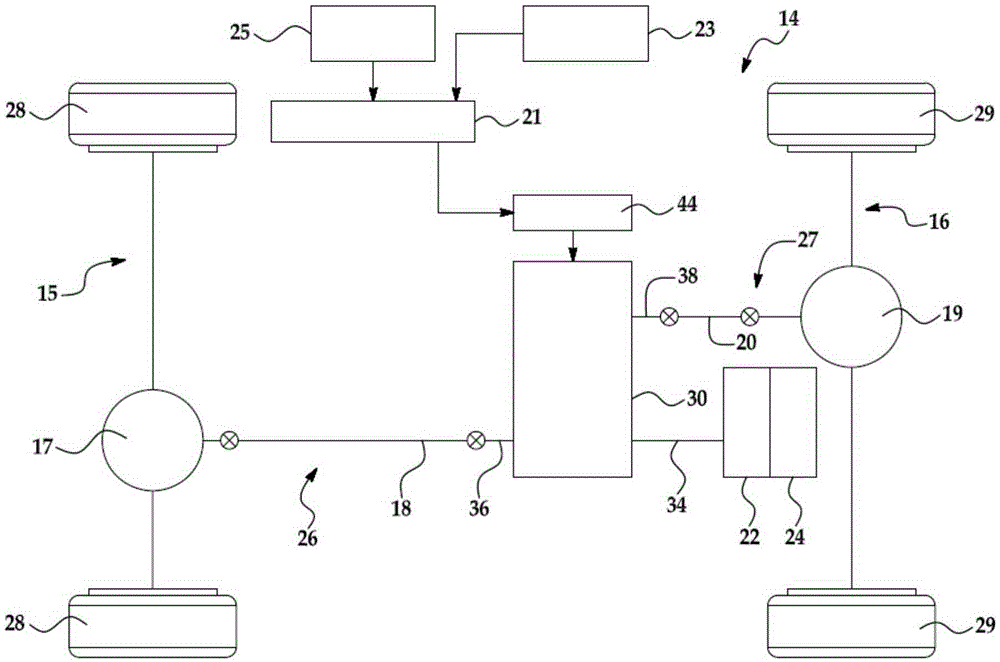

[0016] now refer to figure 1 , the vehicle 14 may include an internal combustion engine 24 and a power transfer device 22 for generating and transmitting drive torque to a front powertrain 26 and a rear powertrain 27 . The vehicle 14 may further include a transmission 30 that transmits drive torque from the internal combustion engine 24 and the power transfer device 22 to the front driveline 26 and the rear driveline 27 . Front driveline 26 may include a pair of front wheels 28 coupled to distally opposite ends of front axle assembly 15 , including front differential 17 , which may be coupled to front drive shaft 18 . An opposite end of the front powertrain 18 can be coupled to a first output shaft 36 of a transmission 30 . The first output shaft 36 can drive the front drive shaft 18 , and the front differential 17 can transmit driving energy to the pair of front wheels 28 through the front axle assembly 15 . Rear driveline 27 may include a pair of rear wheels 29 coupled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com