Precision ball reducer

A technology of reducer and deceleration equipment, which is applied in the direction of mechanical equipment, belt/chain/gear, transmission device, etc. It can solve the problems of small number of teeth, low power conversion efficiency, and large friction coefficient, so as to improve output torque and power High conversion efficiency and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

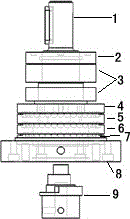

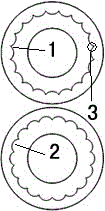

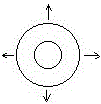

[0018] The motor drives the input shaft 9 to rotate, and the input shaft 9 is designed with a dynamic balance structure. The eccentric part (eccentric value p) in the middle of the input shaft 1 drives the fluctuation disc 5 to rotate. Bearing connection, when the input shaft 1 rotates, the wave plate produces two movements, one motion is to follow the circular rotation of the input shaft, and the other motion is to fluctuate with the eccentric part of the input shaft, and the anti-rotation plate 6 restricts the circular rotation of the wave plate 5 , let the fluctuation plate 5 do translational cross fluctuation according to the eccentric value p (see image 3 ). At this time, any point on the fluctuation plate 5 (take point D) will have the harmonic generated by the superposition of the point D's own position and translation fluctuation (see figure 2 Middle 1), assuming that the ball is fixed above the point D, according to the relative movement, the ball can walk out a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com